Automobile interior and exterior decoration coating structure with lightproof decorative patterns

An automotive interior and exterior decoration, transparent coating technology, applied in the coating, metal material coating process, vacuum evaporation plating and other directions, can solve the decorative effect of a single color, difficult to achieve pattern decoration effect, difficult to achieve light transmission, problems such as wave penetration, to achieve the effect of beautiful overall appearance and good wave permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

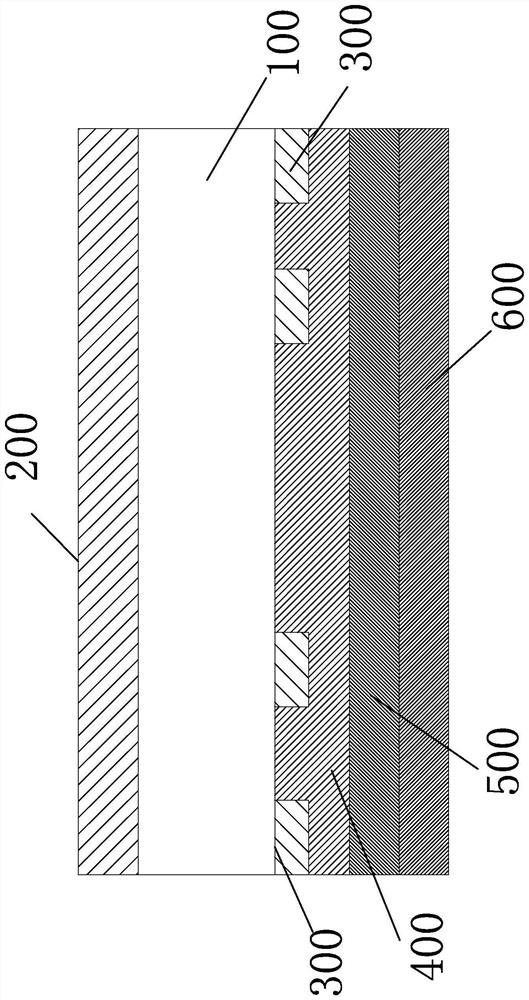

[0020] like figure 1 As shown in the figure, the coating structure for the interior and exterior of the automobile with the opaque decorative pattern can realize the wave-transmitting function when a non-conductive coating such as indium is plated, and includes a material layer 100, a first coating layer and a second coating layer, The material layer 100 is a transparent material, the material of the material layer 100 is one of PC, PMMA or ABS material, the upper surface of the material layer 100 has a front protective layer 200, the front protective layer 200 is a transparent coating, the front protective layer 200 It is realized by one of spraying, flow coating or printing. The first coating layer and the second coating layer are interlaced together, and a partial area of the second coating layer is stacked together with the first coating layer and is located on the lower surface of the material layer 100. The remaining area of the coating layer is directly located on t...

Embodiment 2

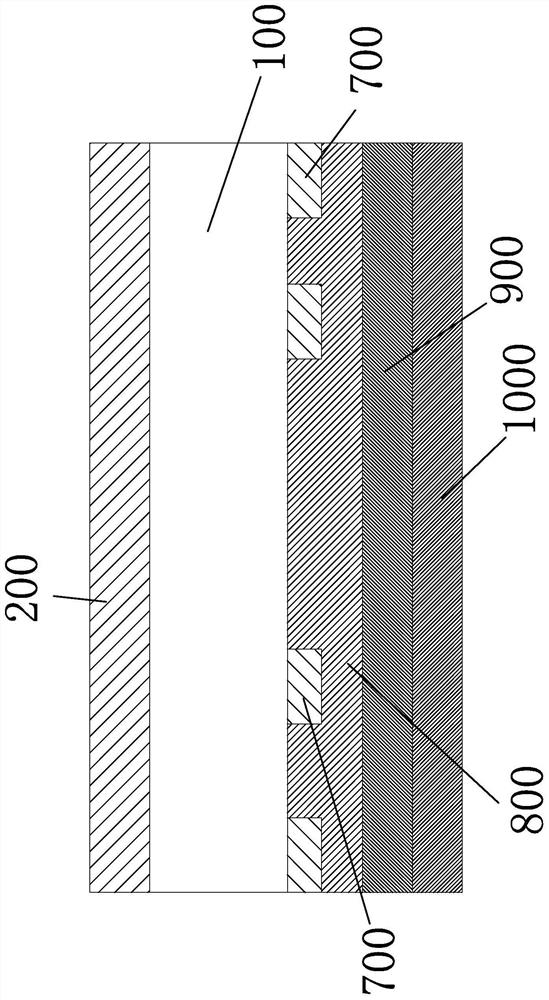

[0023] like figure 2 As shown, when the first coating is the second colored coating 700 of black or other colors, and the second coating is the transparent coating 800, the second colored coating 700 can be realized by spraying, curtain coating, printing, etc. The second colored coating 700 is located under the material layer 100. The second colored coating 700 does not cover the entire lower surface area of the material layer 100. The second colored coating 700 only covers a partial area of the lower surface of the material layer 100. After the second colored coating 700 is applied to the entire back surface of the layer 100, then laser engraving is performed, and the upper part of the material layer 100 is peeled off to form the second colored coating 700, wherein the second colored coating 700 and the transparent coating 800 are staggered. Together, a partial area of the transparent coating 800 is laminated with the second colored coating 700 and is located on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com