Preparation method of nano hard alloy

A cemented carbide and nanotechnology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of tungsten alloy physical properties, tungsten carbide grain growth, uneven structure, etc., to improve the uniformity of material distribution , reduce the abnormal growth of grains, and improve the effect of transverse fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present application provides a preparation method of a nanometer cemented carbide, comprising the following steps:

[0035] Step S1: provide a ball mill, dissolve the dispersant in part of absolute ethanol, add powdered tungsten carbide, powdered cobalt, nucleation inhibitor, paraffin and remaining absolute ethanol into the ball mill, and continue ball milling to obtain the first nano-hard It is made of alloy compound, and the dispersant includes fatty alcohol polyoxyethylene ether, polyglycerol-6 laurate and stearic acid.

[0036] Fatty alcohol polyoxyethylene ether is a good surfactant, which can be well dissolved in paraffin to improve the activity of paraffin molecules and accelerate the dispersing speed of paraffin in the mixture; moreover, fatty alcohol polyoxyethylene ether can also reduce the The surface activity of powdered tungsten carbide and cobalt can improve the dispersibility of the powder; however, the fatty alcohol polyoxyethylene ...

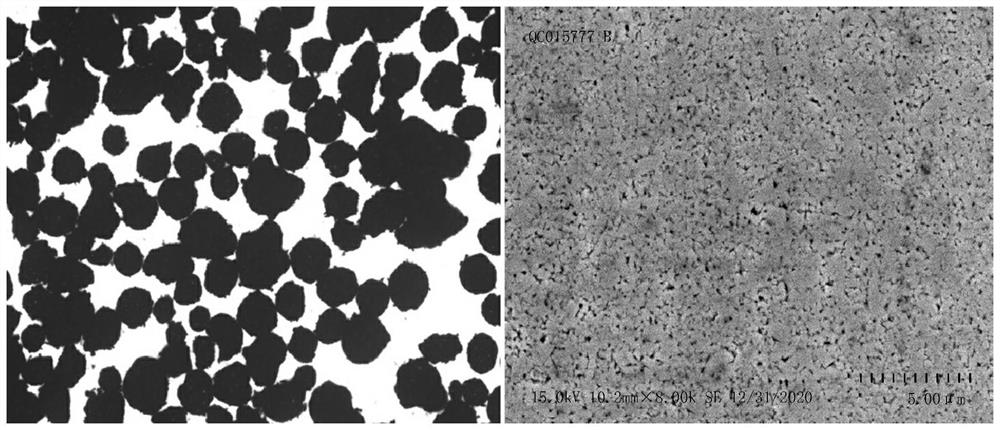

Embodiment 1

[0070] The embodiments of the present application provide a method for preparing a nano-hard alloy, which includes the following components in parts by mass: 89.1 parts of tungsten carbide, 10 parts of cobalt, 0.4 parts of vanadium carbide, 0.5 parts of chromium carbide, 2 parts of parts of paraffin, 27 parts of absolute ethanol, and 2 parts of dispersant. Wherein, the dispersing agent includes 30% by mass of fatty alcohol polyoxyethylene ether, 20% by mass of stearic acid and 50% by mass of polyglycerol-6 laurate.

[0071] The mixture of the above components was put into a ball mill for mixing and mixing to obtain a slurry (a planetary ball mill with a specification of 1.5L was used in this experiment, and the supplier of the ball mill was Changsha Tianchuang). Among them, the ratio of ball to material is 6:1, and the ratio of solid to liquid is 300ml / Kg. This time, the loading amount of each can is 600g, and the ball milling time is 78 hours, so as to obtain the first cemen...

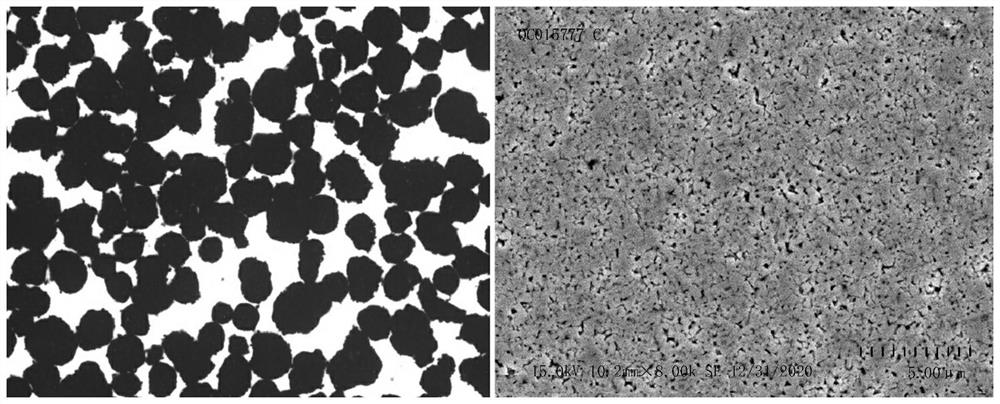

Embodiment 2

[0074] The embodiments of the present application provide a method for preparing a nano-hard alloy, which includes the following components in parts by mass: 89.1 parts of tungsten carbide, 10 parts of cobalt, 0.4 parts of vanadium carbide, 0.5 parts of chromium carbide, 2 parts of parts of paraffin, 27 parts of absolute ethanol, and 2 parts of dispersant. Wherein, the dispersing agent includes 35% by mass of fatty alcohol polyoxyethylene ether, 30% by mass of stearic acid and 35% by mass of polyglycerol-6 laurate.

[0075] The mixture of the above components was put into a ball mill for mixing and mixing to obtain a slurry (a planetary ball mill with a specification of 1.5L was used in this experiment, and the supplier of the ball mill was Changsha Tianchuang). Among them, the ratio of ball to material is 6:1, and the ratio of solid to liquid is 300ml / Kg. This time, the loading amount of each can is 600g, and the ball milling time is 78 hours, so as to obtain the first cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com