Preparation process of heat-preservation adjustable fabric

A preparation process and adjustable technology, which can be applied in the direction of thin material processing, double-sided fleece fabric cutting pile, spray/jet textile material processing, etc., and can solve the problems of fabrics being unavailable and single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The preparation process of the heat-insulating adjustable fabric includes the following steps:

[0038] Step 1: Prepare the material, prepare the yarn for warping, reed the surface warp and ground warp, and load the surface weft and ground weft onto the water jet loom to prepare for jet weaving.

[0039] In step 2, jet weaving is carried out by a water jet loom, alternately jet weaving through a double weave and a towel weave to form an initial fabric, which is wound up.

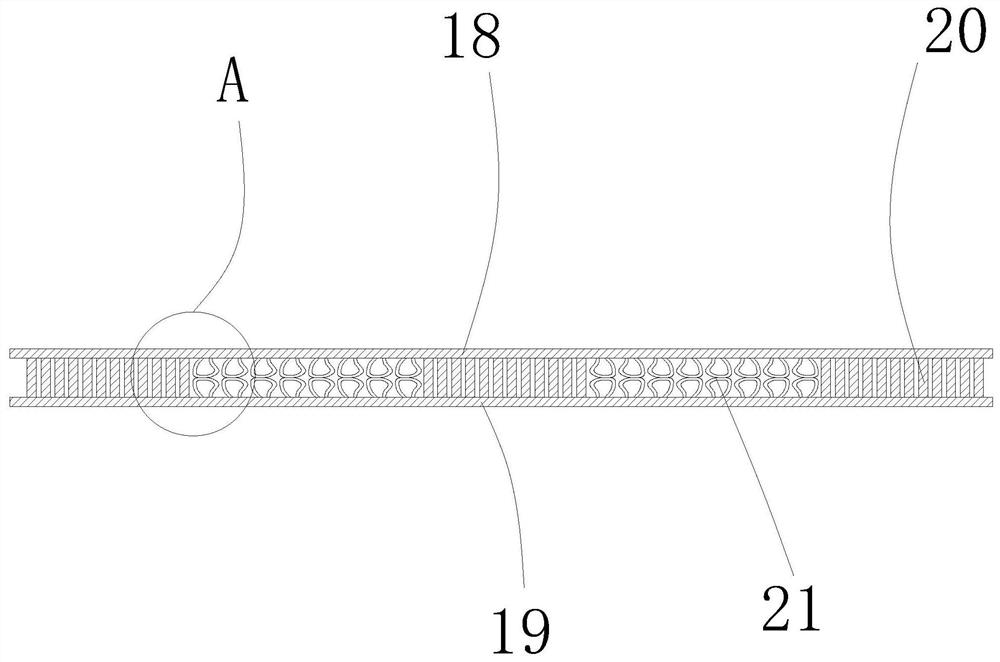

[0040] The initial fabric includes a top layer 18 and a bottom layer 19, the top layer 18 and the bottom layer 19 are fixedly connected by several coil sets, and adjacent coil sets are arranged at intervals, the coil sets are formed by a number of connecting coils 20, the bottom layer 19 and the top layer 18 between the adjacent coil sets The towel coils 21 are fixedly connected, and the towel coils 21 on both sides are arranged facing each other.

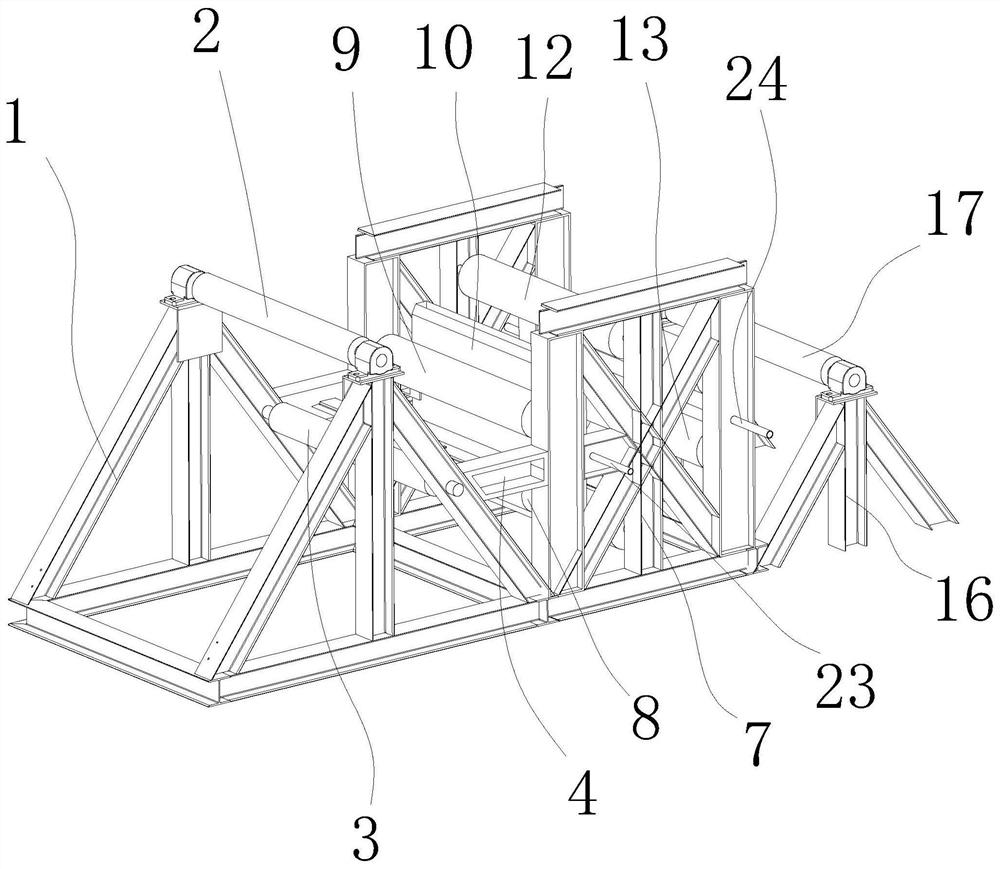

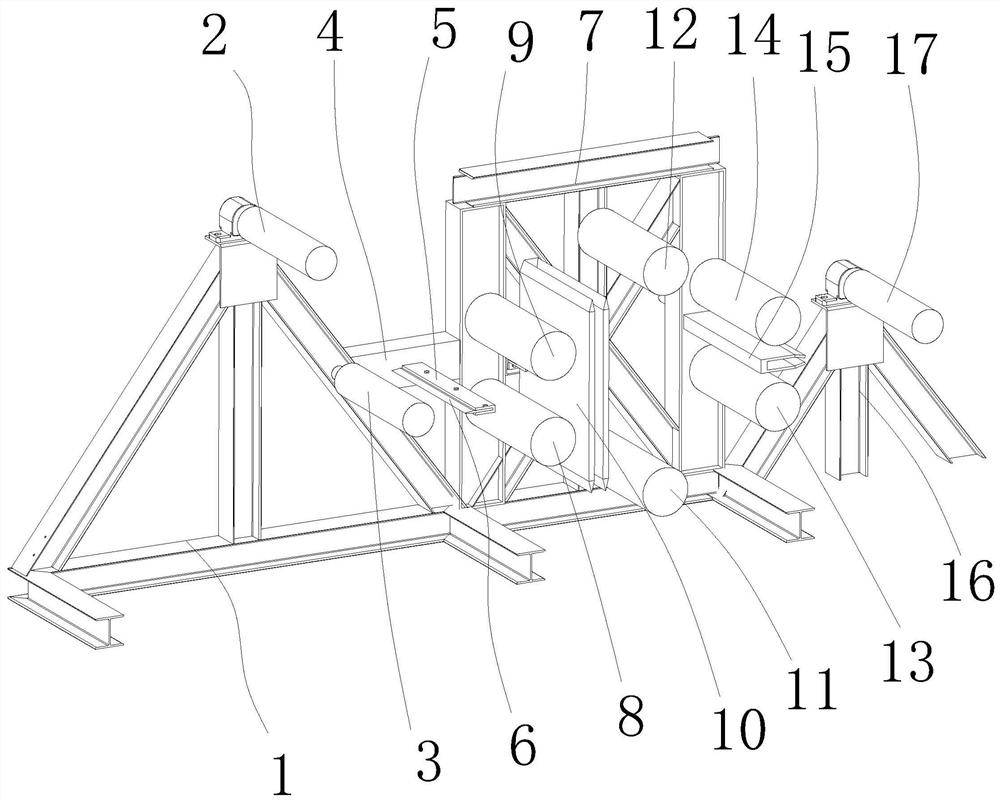

[0041] Step 3, put the initial fabric on the unwind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com