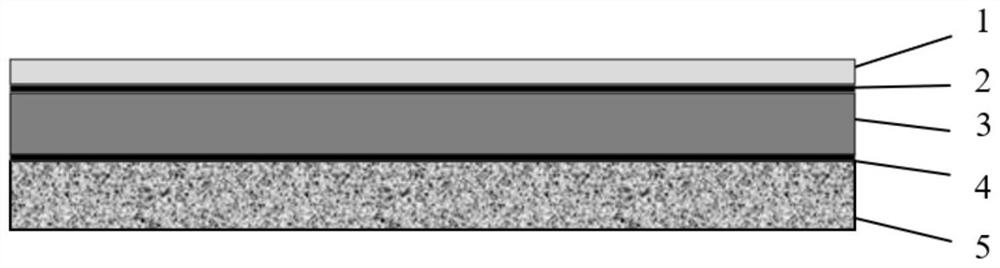

Cement concrete bridge deck asphalt pavement structure and pavement construction method

A cement concrete and asphalt pavement technology, which is applied to bridges, bridge parts, bridge construction, etc., to achieve the effects of improving bearing capacity, reducing construction control difficulty, and improving comfort and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The construction method of the asphalt paving structure of the cement concrete bridge, including the following steps:

[0056] (1) Milling, shot shot or cutting hair treatment of cement concrete bridges, and cleaning and cleaning. The roughness of the bridge deck is determined by the sand laying method to be 0.7mm.

[0057] (2) Spray the waterproof adhesive layer of non -adhesive wheel emulsion asphalt on the processed cement concrete bridge surface Ⅰ4. The intelligent sprinkler sprinkle is used to ensure that the sprinkler is uniform, and the amount of sprinkle is 0.9kg / m. 2 Essence

[0058] (3) After the construction of the waterproof adhesion layer is completed and the emulsification is completely breaking, the multi -functional layer 3 is paved. The asphalt mixture of the multi -functional layer 3 is asphalt, 90 parts of the thickness, 4.6 parts and 0.4 copies of the compound modified asphalt. Composition of Xuanwu Rock Fiber.

[0059] Multi -functional layer 3 hybrid m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com