Continuous wind tunnel airflow temperature cooling method

A cooling method and wind tunnel technology, applied in aerodynamic tests, machine/structural component testing, instruments, etc., can solve the problems of difficult control, wide range of heat exchange requirements, high precision requirements, etc., and achieve reasonable technical reserves Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

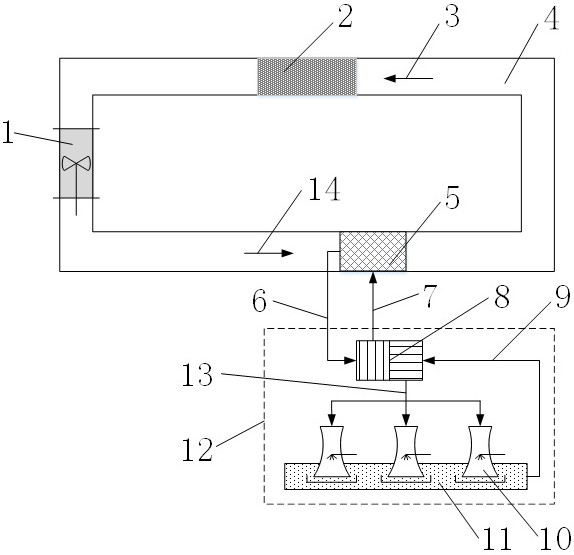

[0058] The circulating water system 12 of this embodiment adopts the form of a combination of an open water circuit and a closed water circuit. The open water circuit is ordinary industrial water, and the water volume is about 28,000 m 3 / h, the pipe material is carbon steel, which can effectively reduce the construction cost and operating cost under the premise of meeting the needs of use; the closed water circuit is specially treated demineralized water, and the water volume is about 22000m 3 / h, the pipe material is stainless steel, to ensure that the water flow will not be rusted, scaled and blocked in the narrow flow channel, so as to ensure the safety of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com