Dike foundation seepage deformation device under vertical load effect

A technology of vertical load and seepage deformation, which is applied in embankment engineering, flood control and flood fighting, and can solve problems such as unguaranteed embankment quality, high randomness, and complicated situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

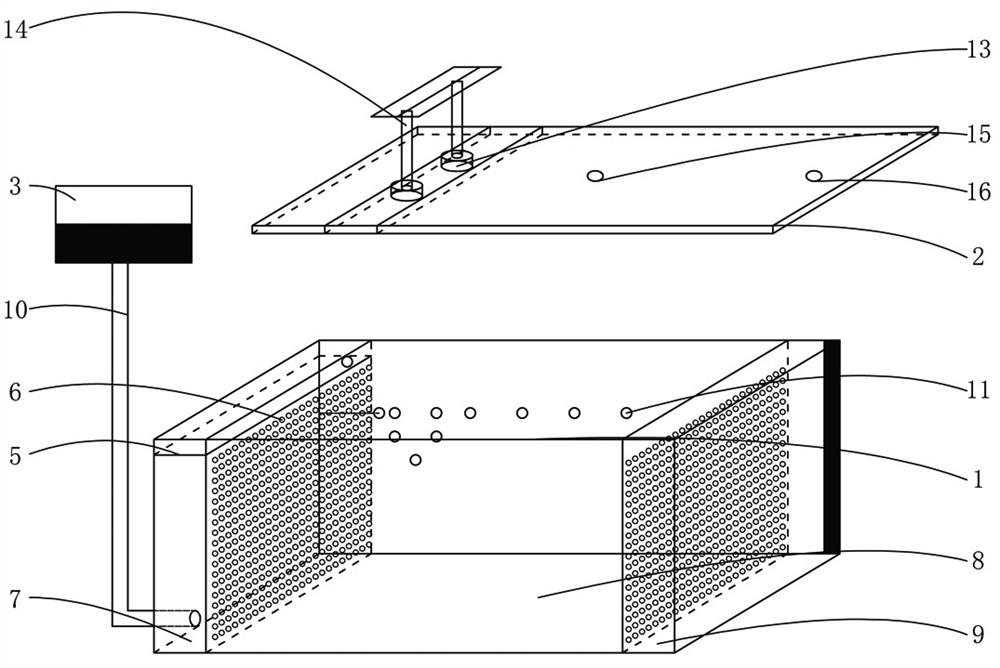

[0026] Embodiment 1: This embodiment aims to provide a seepage deformation device for embankment foundation under vertical load, which is mainly used in the study of the seepage capacity of embankment foundation, so as to simulate the pressure of seepage water in the embankment foundation under vertical load In order to ensure the safety of the embankment project, in this embodiment, a model groove 1 and a plastic anti-seepage composite vertical plate 4 are provided mainly for the seepage deformation device of the embankment foundation in this embodiment.

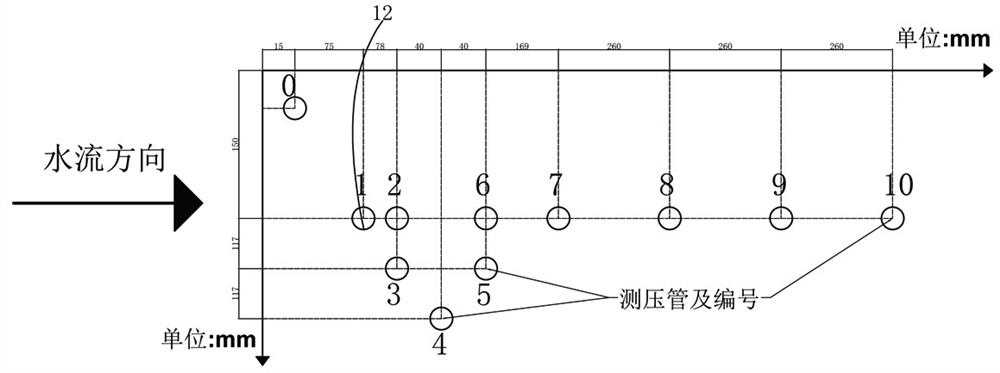

[0027] In a specific structure, such as Figure 1-3As shown in , a device for seepage deformation of embankment foundation under vertical load, including model groove 1, loading plate 2, water head control box 3 and plastic anti-seepage composite vertical plate 4, model groove 1 is surrounded by pressure bearing Plate 5, the inner sides of the pressure plates 5 on both sides are provided with sand separators 6. The sand sep...

Embodiment 2

[0029] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the difference lies in the further description of the specific structure of the water head control box 3 in this embodiment.

[0030] In a specific structure, such as figure 1 As shown in the figure, the water head control box 3 guides the water into the pressure-bearing area 7 through the water pipe 10 to simulate the water near the embankment foundation; the two sand separators 6 are respectively arranged at a distance of 50 centimeters from the pressure-bearing plates on both sides, close to the water head. The pressure-bearing area 7 on the side 3 of the control box is used to simulate the water level, and it is far away from the flat water area 9 on the side of the head control box 3 for water storage.

Embodiment 3

[0031] Embodiment 3: This embodiment is basically the same as Embodiment 1, and the difference lies in the further description of the specific structure of the loading board 2 in this embodiment.

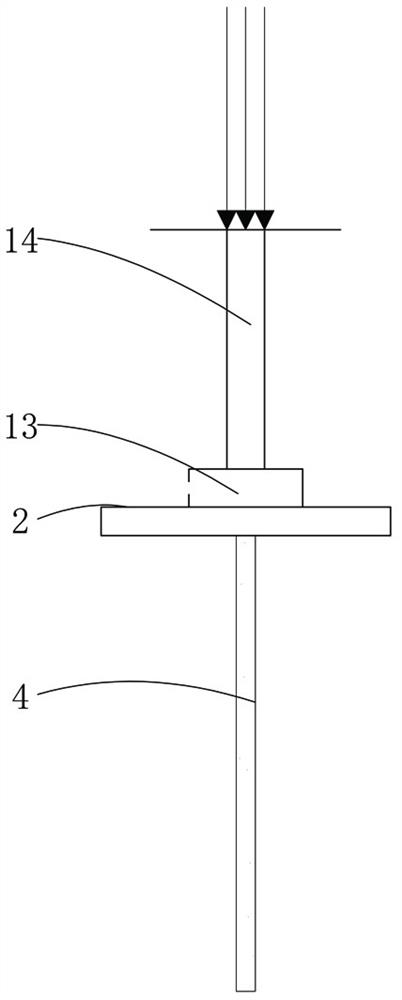

[0032] In a specific structure, such as Figure 3-6 As shown in , the loading plate 2 is provided with four guide cylinders 17 distributed in a rectangular shape, and a connecting rod 18 is inserted into the guide cylinder 17. The lower end of the heavy object is fixed with a flat plate 19; the plastic anti-seepage composite vertical plate 4 simulates the anti-seepage structure in the embankment foundation, which can only simulate vertical infiltration, and the embankment foundation also has lateral infiltration, which will also affect the research structure. The structure of the lateral permeability of the sand in the groove area 8 is not comprehensive enough. The guide cylinder 17, the connecting rod 18 and the flat plate 19 are set together. When in use, the flat plate 19 is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com