T-beam production control method and system

A production control method and production line technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problem of lack of specific conditions to optimize the production period of T-beams, etc., to achieve the shortest construction period arrangement, simplify the algorithm, and improve the accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] Let: n be the total number of T beams to be processed, Y and Z respectively represent the length and width of the workshop, J is the total number of production lines, and I is the total number of processes.

[0094] It is assumed that the production of T beams in this embodiment has three processes of ABC, the production workshop has four production lines of A, B, C, D, and 7 pieces of T beams to be processed. That is, in this embodiment, the T beam production is divided into three processes, and the three processes are respectively expressed as process A, process B, and process C according to the processing order.

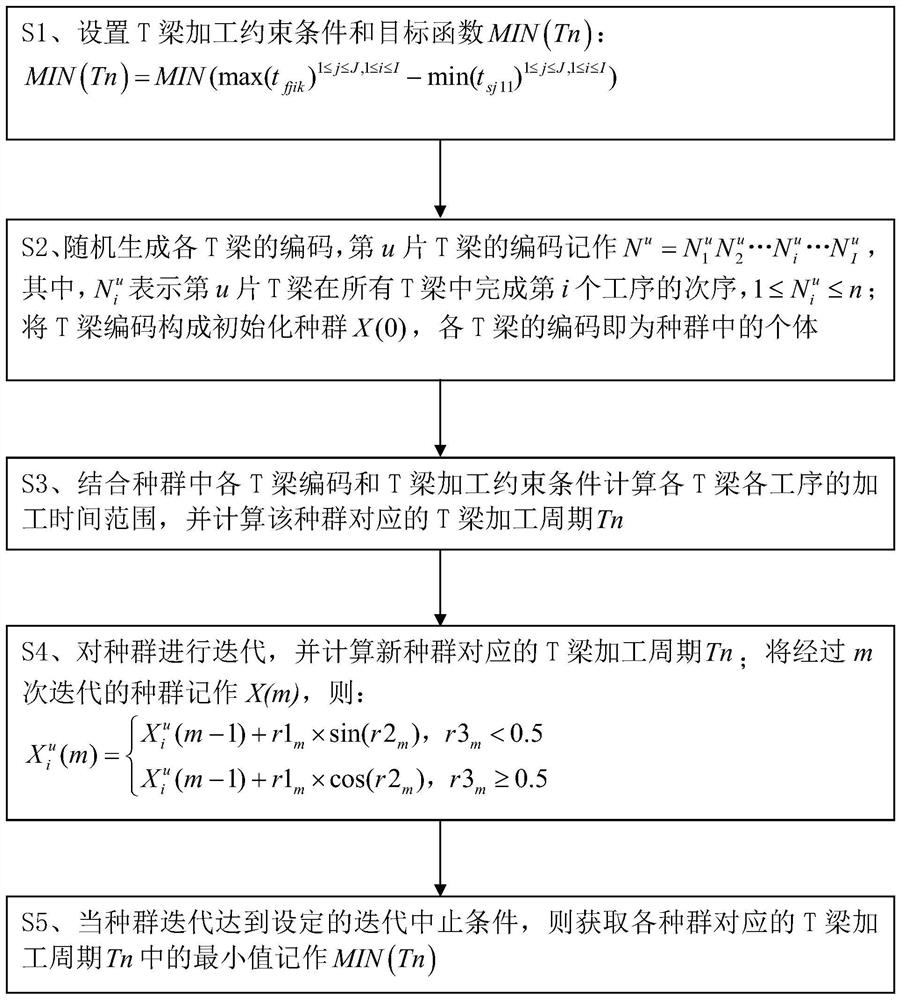

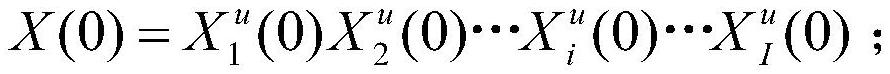

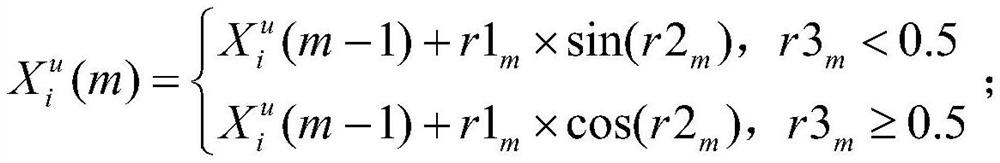

[0095] Step 1: Establish the objective function

[0096] The objective function is:

[0097] MIN(Tn)=min(max(t fjik ) 1≤j≤J,1≤i≤I -min(t sj11 ) 1≤j≤J,1≤i≤I ) (1)

[0098] Among them, n represents the total number of T beams to be processed, J represents the total number of T beam production lines, and I represents the total number of processes on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com