Flotation foam grade calculation method and device, electronic equipment and medium

A foam and grade technology, applied in the field of collaborative calculation of process data, can solve the problems of inability to give flotation foam grade, intelligent control restrictions, etc., and achieve the effect of intelligent control, strong interpretability, and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

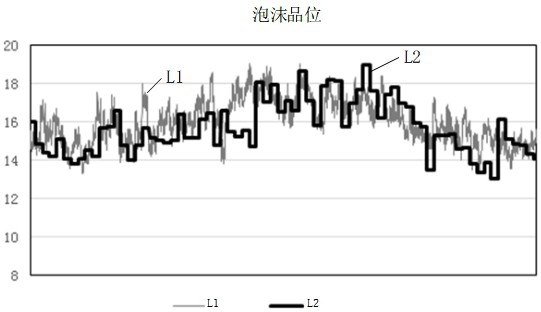

Examples

Embodiment 1

[0041] The embodiments of the present disclosure provide a method for calculating the grade of flotation froth.

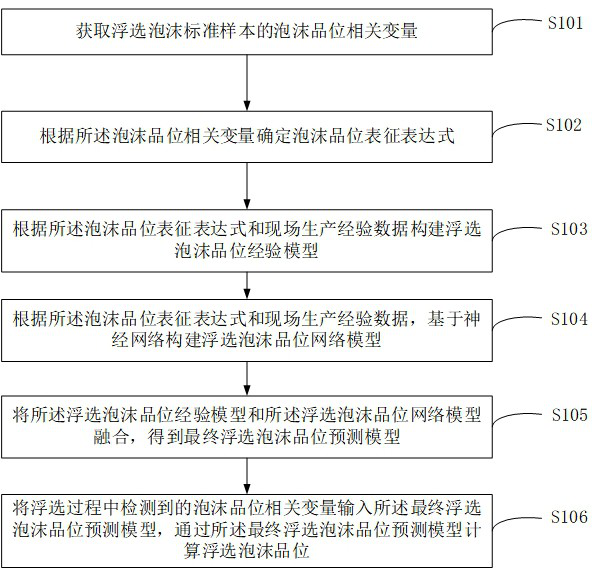

[0042] Specifically, see figure 1 , the calculation method of flotation froth grade includes:

[0043] Step S101, obtaining the froth grade-related variables of the flotation froth standard sample.

[0044] In this embodiment, the variables related to foam grade at least include: relative mineralization degree of foam, foam flow rate matrix, raw ore grade, grinding product particle size and foam color characteristic matrix.

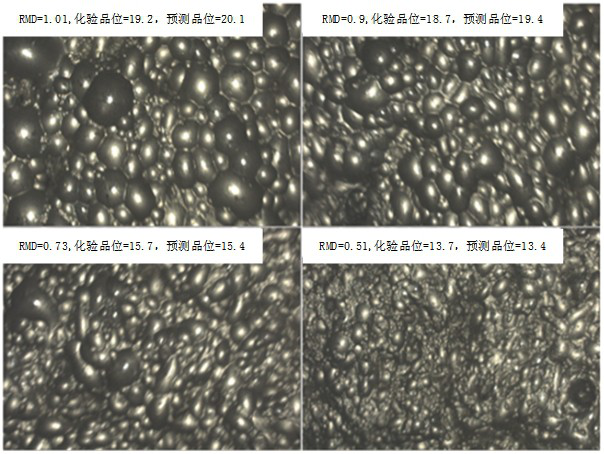

[0045]Carry out process inspection for flotation foam process, collect production data and establish related database. The main factors affecting the foam grade are analyzed, and the factors affecting the foam grade at least include the properties of the raw ore, the quality of the grinding products, and the characteristic parameters of the foam. Observe the mineralization phenomenon of the flotation froth and determine the installation pos...

Embodiment 2

[0197] In addition, embodiments of the present disclosure provide a flotation froth grade calculation device.

[0198] Specifically, as Figure 10 As shown, the flotation froth grade calculation device 500 provided in this embodiment includes:

[0199] The obtaining module 501 is used for obtaining the froth grade-related variables of the flotation froth standard sample, the froth grade-related variables at least include: the relative mineralization degree of the froth, the froth flow velocity matrix, the raw ore grade, the particle size of the grinding product and the froth color feature matrix;

[0200] A determination module 502, configured to determine a foam grade representation expression according to the foam grade related variable;

[0201] The first building module 503 is used for constructing an empirical model of flotation froth grade according to the froth grade characterization expression and on-site production experience data;

[0202] The second building modul...

Embodiment 3

[0230] In addition, an embodiment of the present disclosure provides an electronic device, including a memory and a processor, wherein the memory stores a computer program, and when the computer program runs on the processor, the flotation froth grade provided in Embodiment 1 is executed calculation method.

[0231] The electronic device provided in this embodiment can implement the method for calculating the flotation froth grade provided in Embodiment 1, and in order to avoid repetition, details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com