Production safety assessment management method and system for manufacturing industry production line

A technology of safety assessment and management methods, applied in the field of production safety assessment management methods and systems of manufacturing production lines, can solve problems such as failure to consider production stability and the inability of evaluation methods to meet diversity, improve adaptability, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below with reference to the accompanying drawings, through the description of the embodiments, the specific implementation of the present application, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, and the manufacturing process and operation and use methods, etc., are described in further detail to help those skilled in the art to have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention. For the convenience of description, the directions mentioned in this application are based on the directions shown in the accompanying drawings.

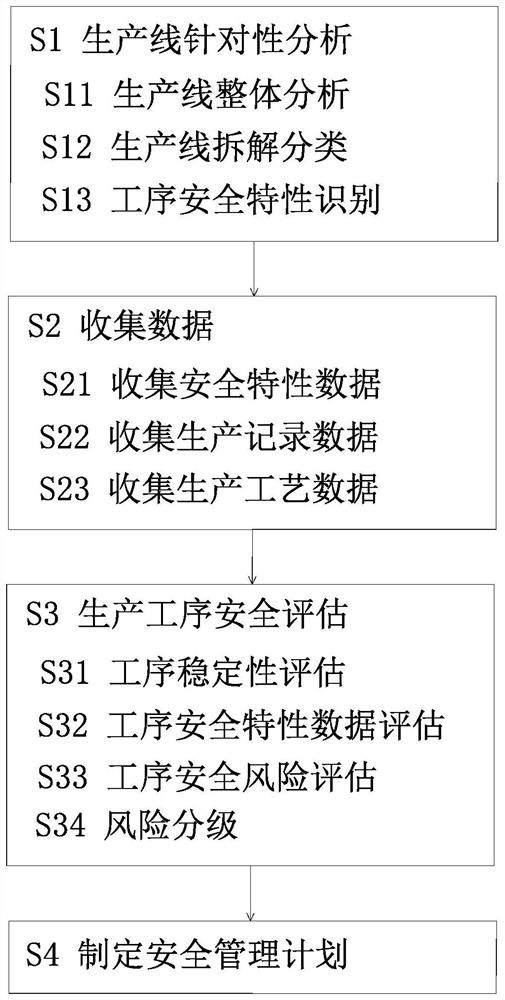

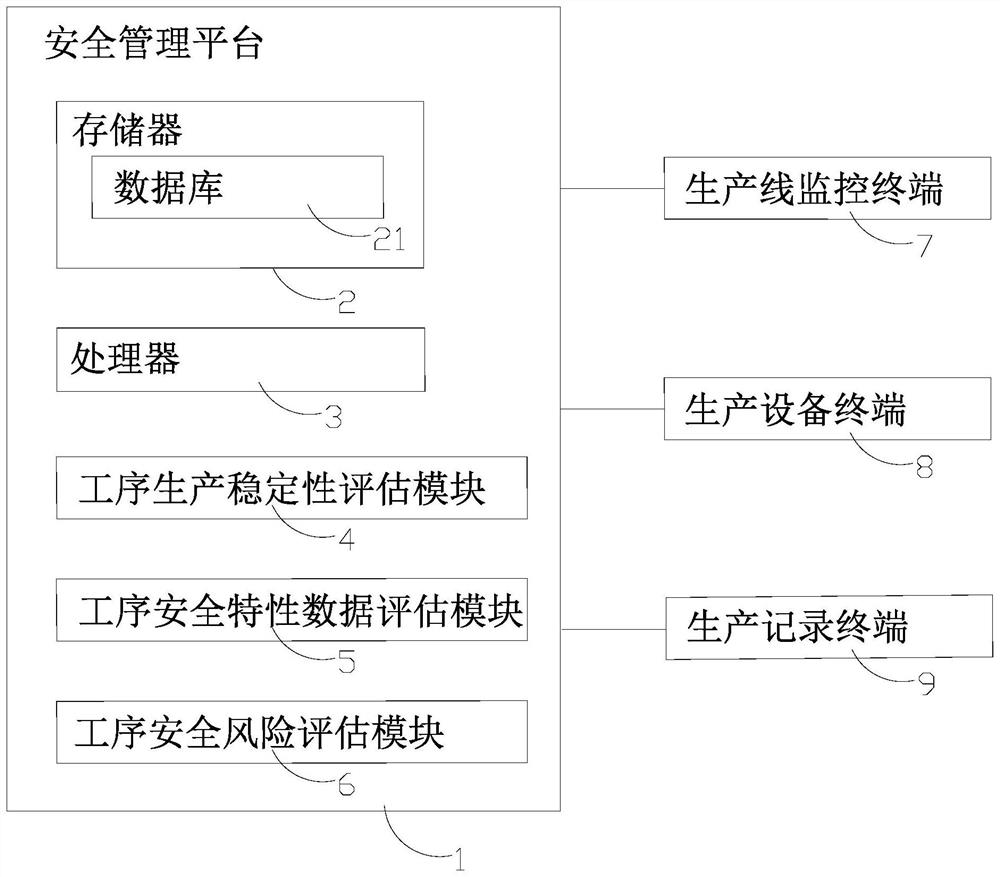

[0046] refer to Figure 1-Figure 2 As shown, a production safety assessment management method for a manufacturing production line includes the following steps:

[0047] Step S1, the targeted analysis of the production line, first analyze the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com