Pole piece lithium supplementing all-in-one machine and lithium supplementing method thereof

An all-in-one machine and pole piece technology, which is applied in electrode manufacturing, battery electrodes, structural parts, etc., can solve the problems affecting the quality of lithium supplementation of pole pieces, the lithium film and pole piece are prone to offset, and the lithium film and pole piece are pressed. Problems such as low precision, to achieve the effect of high precision and guaranteed precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

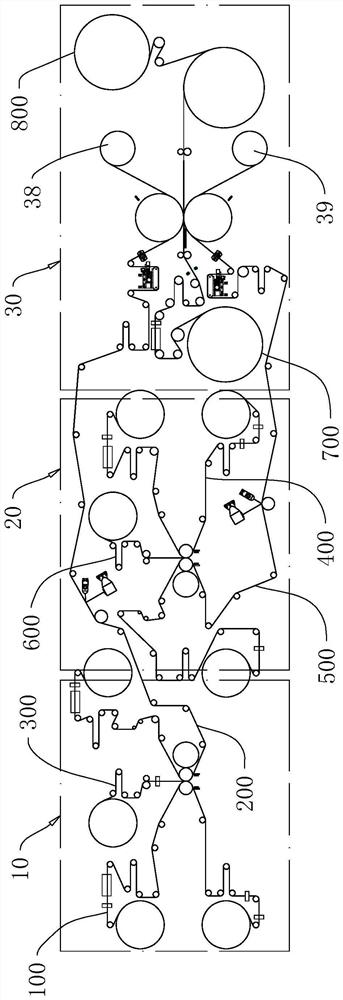

[0053] Attached to the following Figure 1-12 This application will be described in further detail.

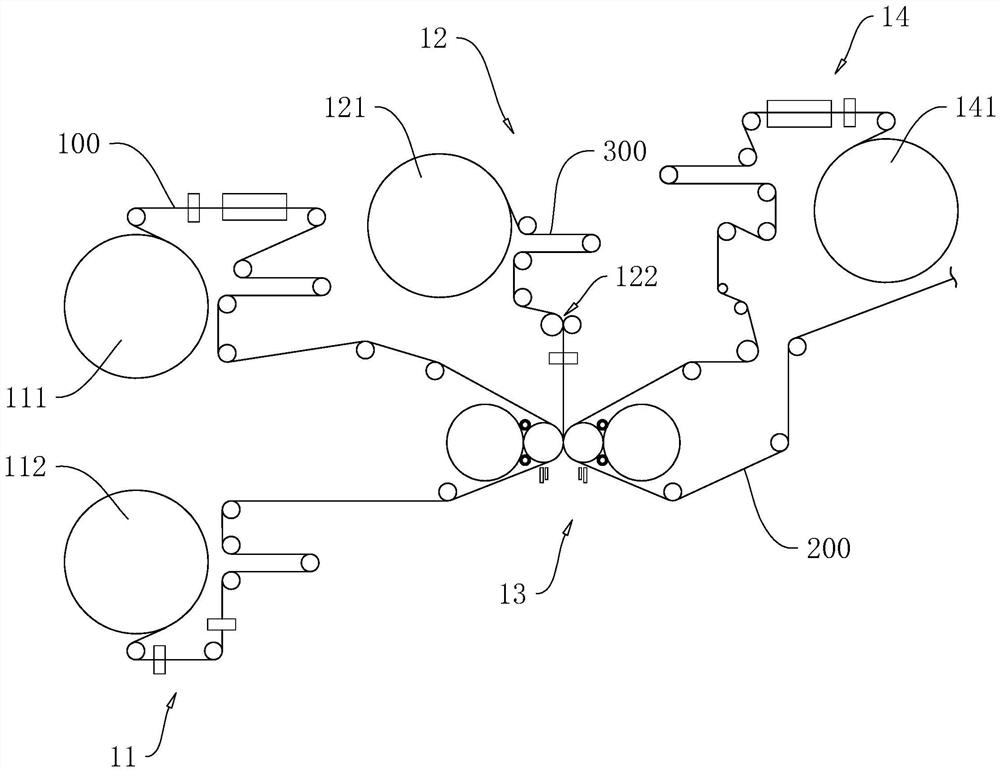

[0054] The embodiment of the present application discloses an all-in-one machine for replenishing lithium with a pole piece. refer to figure 1 , the pole piece 700 lithium supplement production line includes a first rolling device 10, a second rolling device 20 and a laminating device 30. The first rolling device 10 and the second rolling device 20 roll the first lithium strip 300 into a thin lithium film, thin lithium The film is attached to the protective film for transportation. The first calendering device 10 and the second calendering device 20 generate two protective films with a thin lithium film, and the laminating device 30 pairs the pole piece 700 and two protective films with a thin lithium film. Pressing is performed to cover the thin lithium film on the protective film with the pole piece 700 .

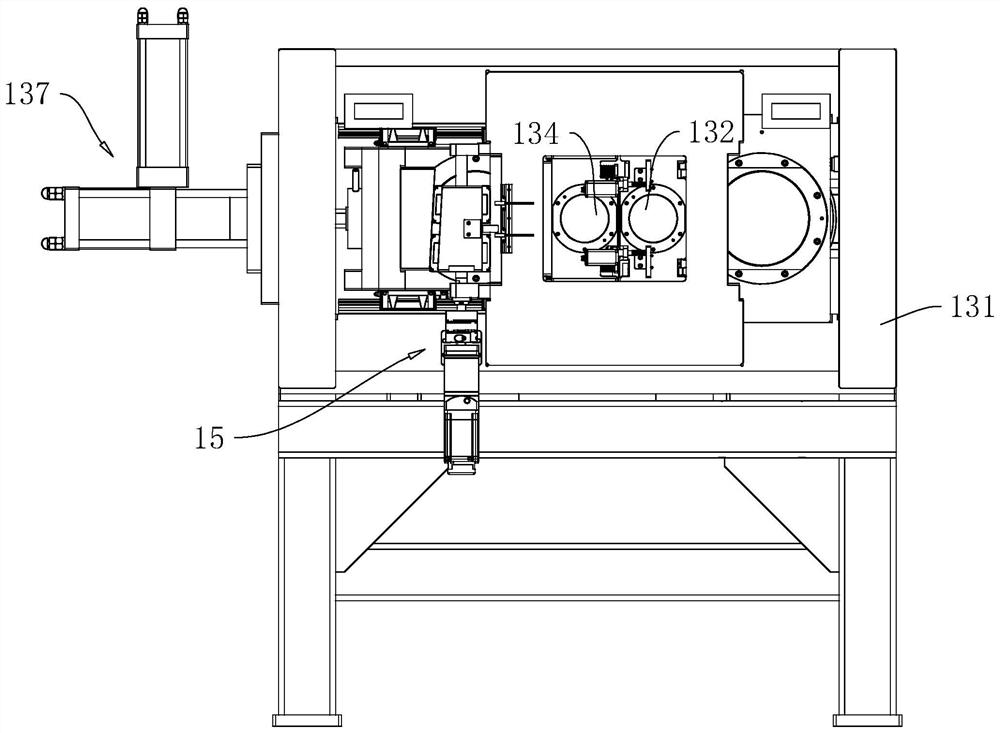

[0055] refer to figure 2 The first calendering device 10 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com