Computer vision-based system for preventing stacking faults in PCB (Printed Circuit Board) lamination hot melting

A computer vision and layer prevention technology, applied in the field of error-proofing systems, can solve problems such as stacking errors and visual fatigue, and achieve the effect of ensuring quality and reducing visual fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

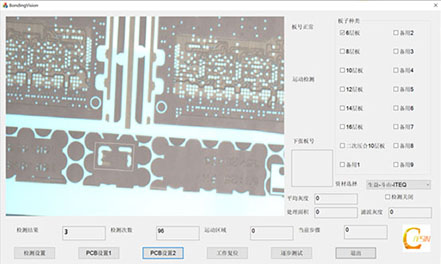

[0029] In order to achieve the above purpose, figure 1 It is a hardware topology diagram showing a device for identifying and detecting the stacking sequence of PCB boards in a conventional hot-melt board forming process.

[0030] The hardware of the equipment to identify and detect the stacking sequence of PCB boards consists of a digital camera, an industrial computer that processes images and IO logic, a cylinder that controls the lifting of the camera, a remote IO module that interacts with the equipment PLC and the signal of the cylinder solenoid valve, solenoid valve, and material detection. It consists of sensors, relays and related mechanical fixing and adjustment components.

[0031] The digital camera adopts an ordinary industrial camera, which is different from an industrial smart camera. It only collects images without processing. The processing is done by software, which can realize more flexible and complex arithmetic processing. It is used to collect image data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com