Isobaric kettle based on oil pressure type sealing

A technology of equal pressure and oil pressure, which is applied in the field of autoclave, can solve the problems of not being able to leak air in time, reduce the use effect, and affect the use of isobar, so as to avoid economic loss, reduce burden, and enhance the effect of warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

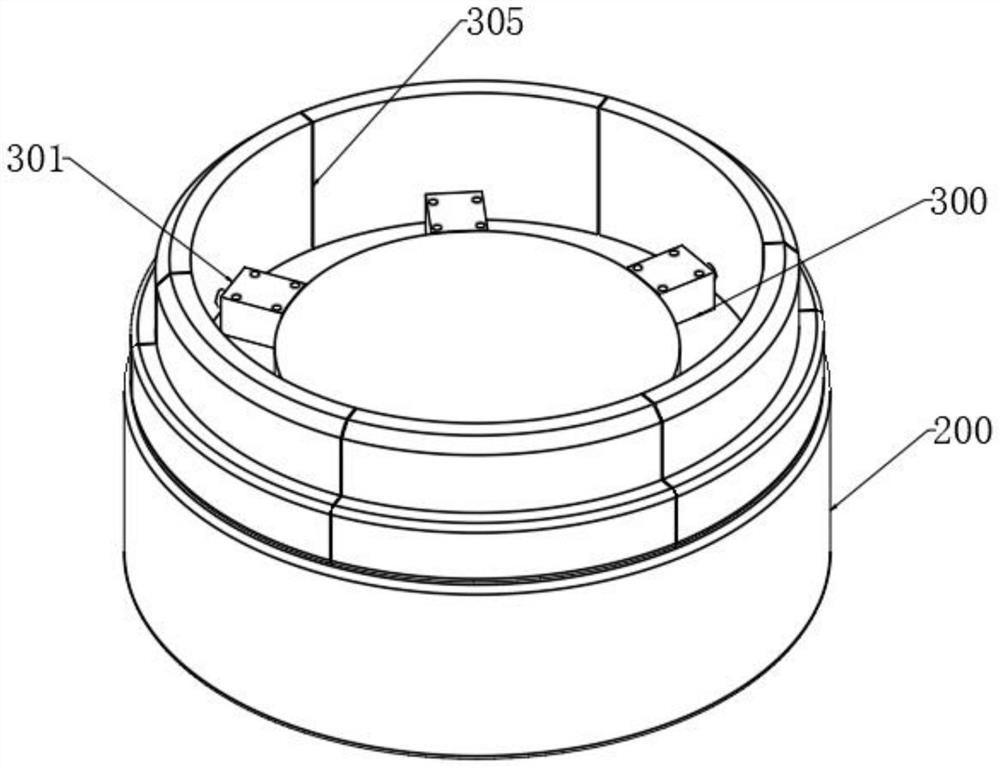

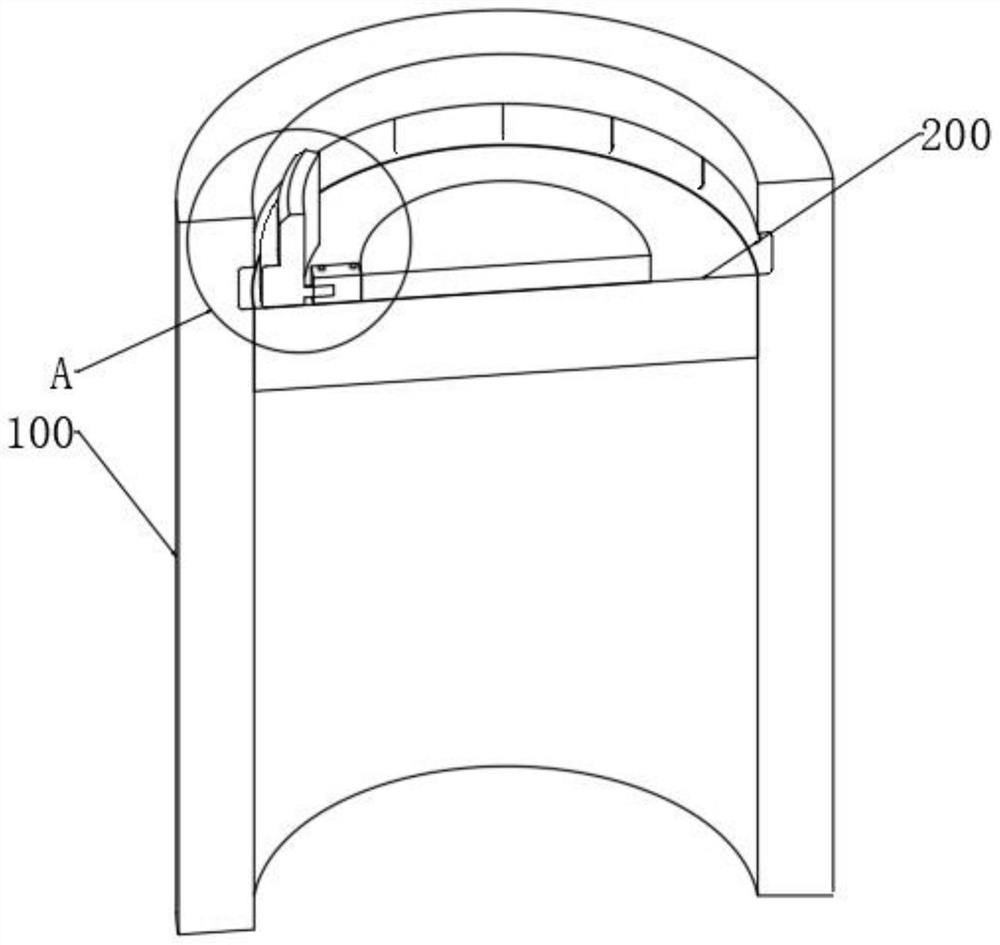

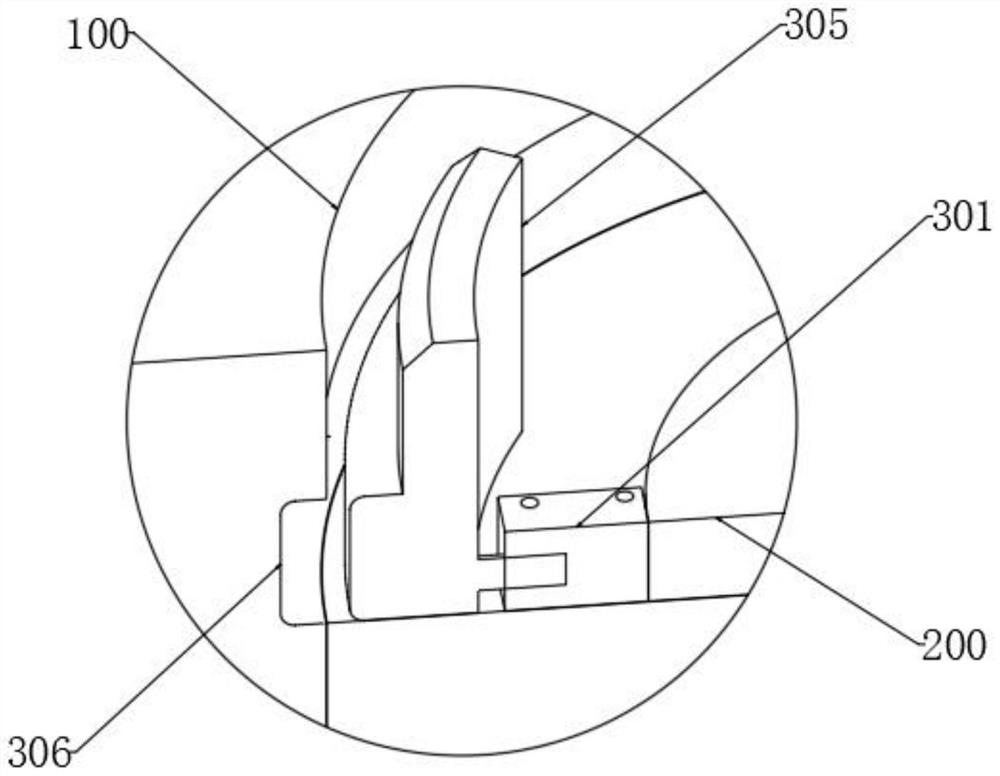

[0043] see Figure 1-9 , an isobaric autoclave based on oil pressure sealing, including an isobaric autoclave barrel 100, an isobaric autoclave cover 200 is provided inside the isobaric autoclave barrel 100, and the isobaric autoclave barrel 100 and the isobaric autoclave cover 200 are arranged A hydraulic engagement mechanism 300 is arranged between the two, and the inside of the hydraulic engagement mechanism 300 is respectively provided with an air leakage alarm mechanism 400 and a warning enhancement mechanism 500. In this solution, the hydraulic engagement mechanism 300 is used to push the buckle 305 and the slot 306 The isobaric autoclave body 100 is snapped and sealed to keep the internal pressure balanced during operation, and the air leakage alarm mechanism 400 drives the driving push rod 403 to press the contact type after the air leakage detector 401 detects the air leakage phenomenon. Control the switch 405 to light up the alarm 407 and sound the alarm, and the war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com