Preparation method of chiral ZIF-8 (at) MXene/CA composite porous material

A technology of ZIF-8 and porous materials, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., to achieve the effects of improving adsorption separation selectivity, improving dispersibility and stability, and improving specific surface area and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

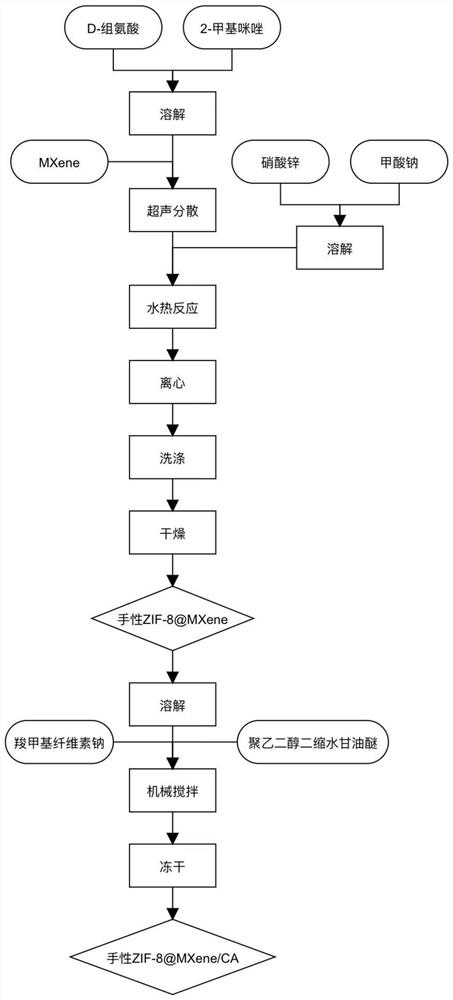

[0026] A preparation method of a chiral ZIF-8@MXene / CA composite porous material, comprising the following steps:

[0027] Step 1. Preparation of chiral ZIF-8@MXene materials: (1) Using D-histidine as the chiral ligand, 0.075g D-histidine and 0.285g 2-methylimidazole were dissolved in 10 mL of deionized In water, prepare 10mL mixed solution of D-histidine and 2-methylimidazole with a certain concentration;

[0028] (2) Dissolve 0.0135g of sodium formate and 0.145g of zinc nitrate in 1mL of deionized water to prepare 1mL of a mixed solution of zinc nitrate and sodium formate with a certain concentration;

[0029] (3) To the solution obtained in (1), add 100 mg of Ti peeled off by etching 3 C 2 -MXene, ultrasonically dispersed for 20min, then add the mixed solution obtained in (2) dropwise, and stir evenly;

[0030] (4) put the mixed solution obtained in (3) into the 85°C reactor for hydrothermal reaction for 24h;

[0031] (5) the mixed solution obtained in (4) is centrifuge...

Embodiment 2

[0038] A preparation method of a chiral ZIF-8@MXene / CA composite porous material, comprising the following steps:

[0039]Step 1. Preparation of chiral ZIF-8@MXene material: (1) Using D-histidine as the chiral ligand, 0.08g D-histidine and 0.29g 2-methylimidazole were dissolved in 12mL of deionized In water, prepare 12mL mixed solution of D-histidine and 2-methylimidazole with a certain concentration;

[0040] (2) Dissolve 0.014g of sodium formate and 0.15g of zinc nitrate in 1mL of deionized water to prepare a mixed solution of zinc nitrate and sodium formate of a certain concentration;

[0041] (3) To the solution obtained in (1), add 100 mg of Ti peeled off by etching 3 C 2 -MXene, ultrasonically dispersed for 30min, then added dropwise the mixed solution obtained in (2), and stirred evenly;

[0042] (4) put the mixed solution obtained in (3) into the 85°C reactor for hydrothermal reaction for 22h;

[0043] (5) the mixed solution obtained in (4) is centrifuged at a cent...

Embodiment 3

[0050] A preparation method of a chiral ZIF-8@MXene / CA composite porous material, comprising the following steps:

[0051] Step 1. Preparation of chiral ZIF-8@MXene material: (1) Using D-histidine as the chiral ligand, 0.07g D-histidine and 0.28g 2-methylimidazole were dissolved in 9mL of deionized In water, prepare 9mL mixed solution of certain concentration D-histidine and 2-methylimidazole;

[0052] (2) Dissolve 0.013g of sodium formate and 0.14g of zinc nitrate in 0.9mL of deionized water to prepare 0.9mL of a mixed solution of zinc nitrate and sodium formate with a certain concentration;

[0053] (3) To the solution obtained in (1), 90 mg of Ti peeled off by etching was added 3 C 2 -MXene, ultrasonically dispersed for 20min, then add the mixed solution obtained in (2) dropwise, and stir evenly;

[0054] (4) put the mixed solution obtained in (3) into the 80°C reactor for hydrothermal reaction for 24h;

[0055] (5) the mixed solution obtained in (4) is centrifuged at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap