Cutting machine for high-precision PTC (Positive Temperature Coefficient) thermosensitive resistor

A thermistor and cutting machine technology, applied in metal processing, etc., can solve the problems of low production efficiency, cutting efficiency, low cutting precision, cumbersome process, etc., and achieve the effect of improving progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

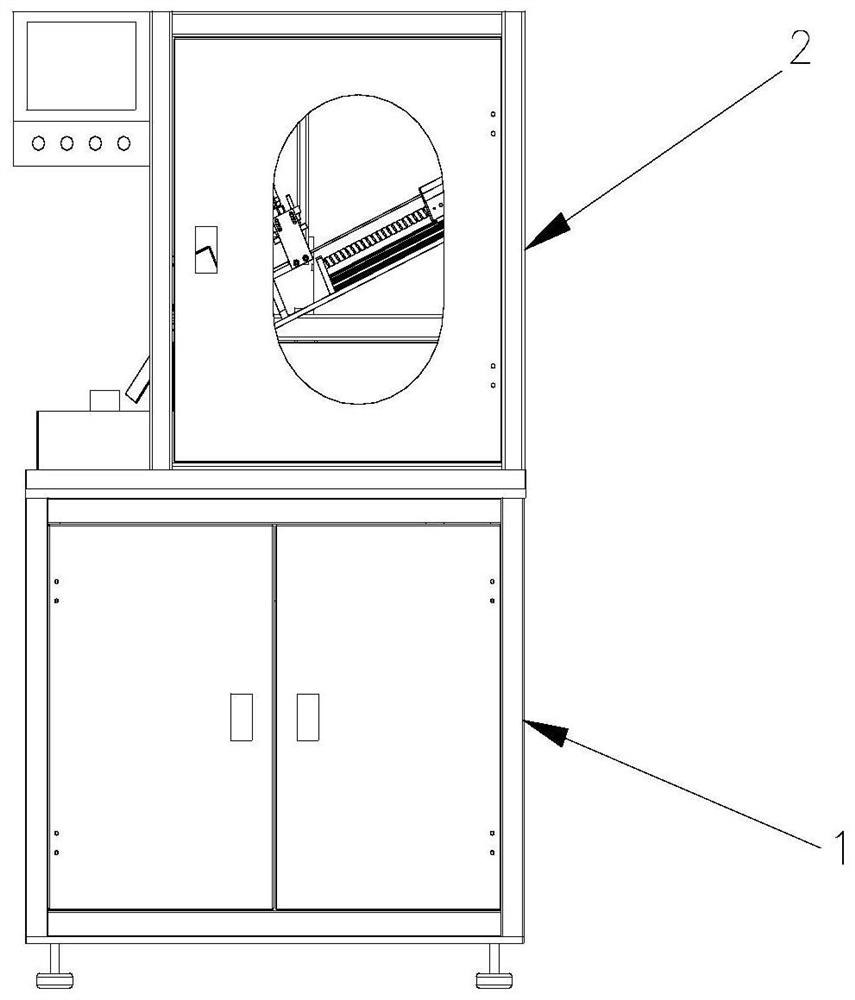

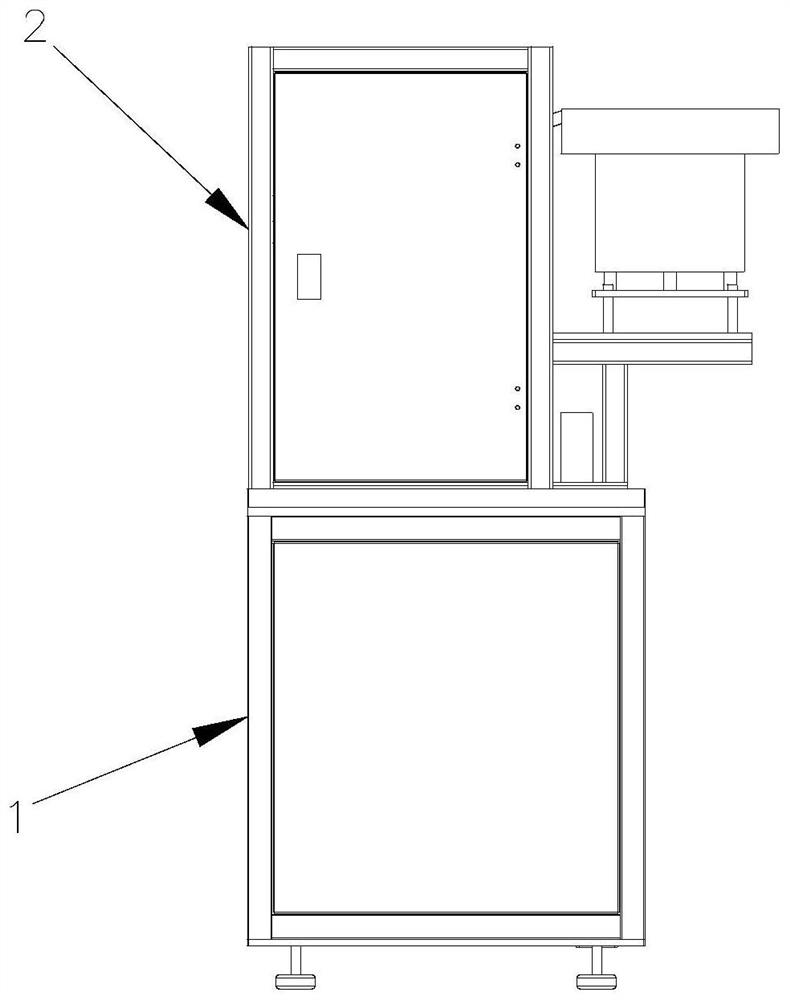

[0029] A high-precision PTC thermistor cutting machine, such as Figure 1-2 As shown, a frame 1 is included, and a cutting working device 2 is mounted above the frame 1 .

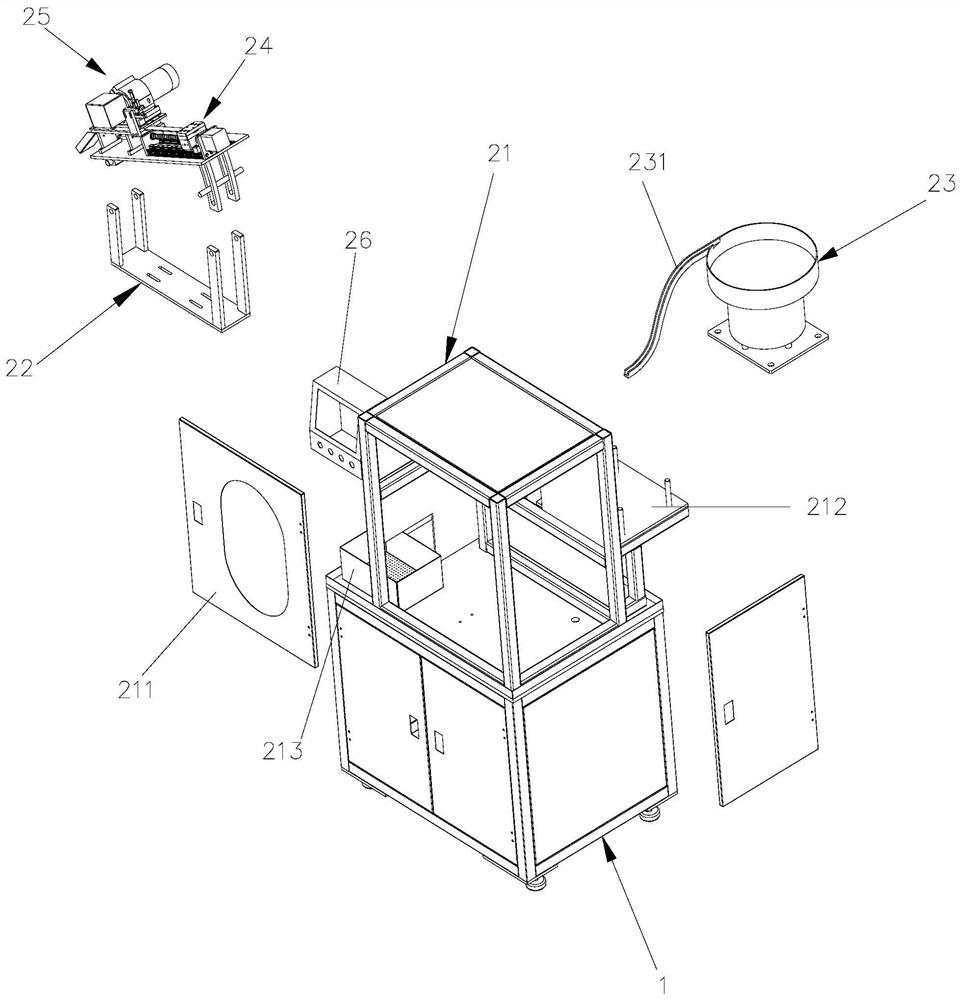

[0030] like image 3 As shown, the cutting working device 2 includes a box body 21 welded with the frame 1 , a mounting frame 22 installed in the box body 21 , and a feeding vibration plate fixed on one side of the box body 21 23. The pushing mechanism 24 fixed on the mounting frame 22, the cutting mechanism 25 fixed on the mounting frame 22 and cooperating with the pushing mechanism 24, and the outside of the box body 21 for controlling cutting The touch screen controller 26 of the working device 2 . The four sides of the box body 21 are all fixed with a cover plate 211 by screws, and the cover plate 211 on the front side of the box body 21 is provided with an observation window. A material vibrating plate 23 is installed, and one side of the box body 21 is clamped with a finished box 213 loaded with th...

Embodiment 2

[0034] In this embodiment, the difference is that the mounting bracket 22 is fixedly installed, such as Figure 7-8 As shown, the mounting frame 22 is non-adjustable. The mounting frame 22 includes a bottom plate 221 fixed with the box body 21 , support columns 222 welded on the four corners of the bottom plate 221 , and the support columns 222 The movably assembled mounting plate 223 is provided below the mounting plate 223 and is used for fixing the threaded seat 226 with the support column 222 by means of bolts. The support columns 222 on the bottom plate 221 are all of the same height, so that the mounting plate 223 can be fixed on the bottom plate 221 horizontally, which is more convenient for material loading.

[0035] Combining Embodiment 1 and Embodiment 2, the operation mode of the cutting machine is: feeding → material arrangement → material cutting → discharging.

[0036] Specifically, the operation program is set through the touch screen controller 26, the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com