High-precision rotary horizontal workbench

A workbench and high-precision technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to reduce production costs, ensure processing accuracy, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

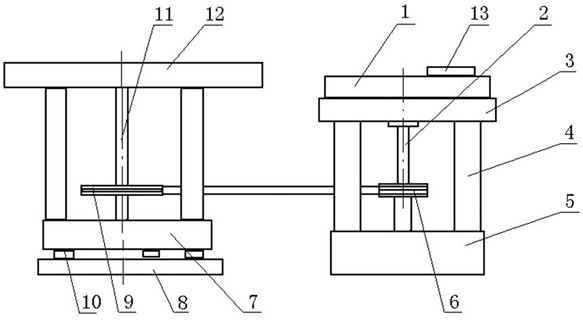

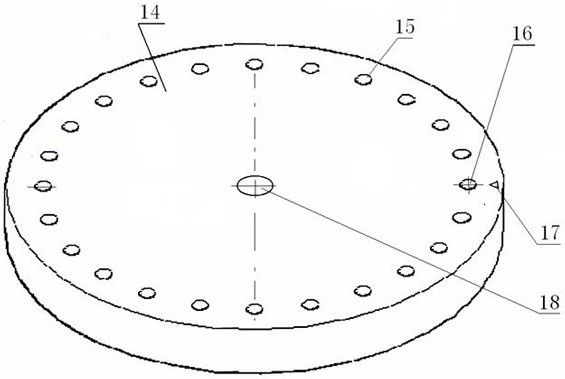

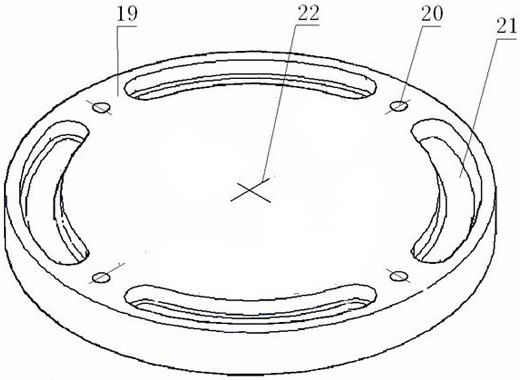

[0020] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a high-precision rotary horizontal workbench includes a workbench 12, a workbench support base 7, a workbench central axis 11, a large pulley 9, four annular support rollers 10, a workbench chassis 8, a rotating disk 1. Rotating shaft 2, small pulley 6, circular base plate 3, bracket 4, auxiliary base 5 and deflection angle assembly 13, worktable 12, worktable support seat 7, worktable central axis 11, large pulley 9 and support roller 10 is an integrated structure, the central axis 11 of the worktable is located below the worktable 12, the large pulley 9 is installed on the central axis 11 of the worktable, the four supporting rollers 10 are located under the supporting seat 7 of the worktable, and the four supporting rollers 10 Make a circular motion on the worktable chassis, the auxiliary base 5 is located beside the worktable chassis 8, the circular base plate 3 is fixed above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com