Automatic gas meter packaging system

A gas meter and automatic technology, which is applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of high packaging operation cost, high operation cost, and low efficiency of manipulators, achieve efficient and continuous packaging operations, and reduce operating costs , the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

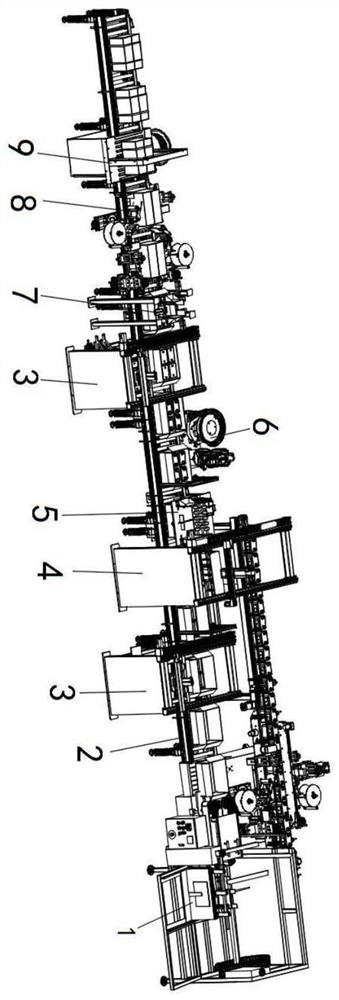

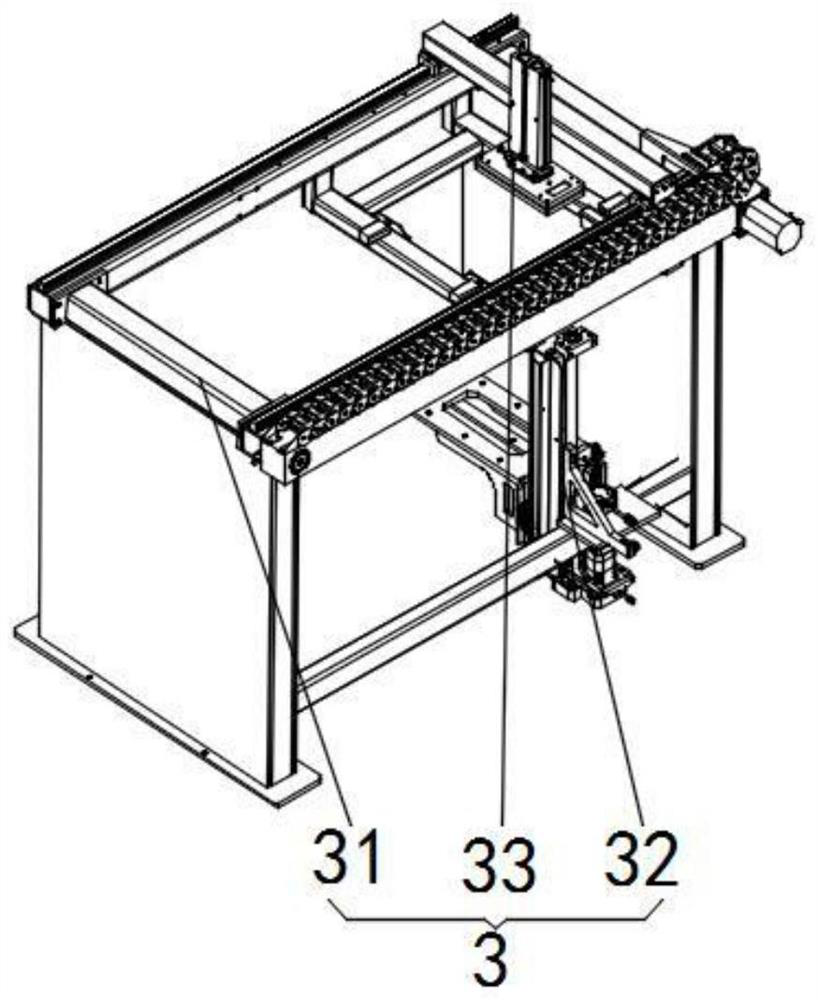

[0044]A gas meter automatic packing system of this embodiment, such as figure 1 As shown in the figure, it includes a packing box transmission line 2, and the packing box transmission line 2 is sequentially provided with a packing box unpacking machine 1, a gas meter three-axis pickup device 4, a box body labeling machine 8, and a box body baler 9 along the transmission direction. Between the packing box unpacking machine 1 and the inlet end of the gas meter three-axis pickup device 4 and between the outlet end of the gas meter three-axis pickup device 4 and the box labeling machine 8, an inner support placing device 3 is provided; figure 2 As shown, the inner support placing device 3 includes an inner support support frame 31 mounted across the top of the packaging box transmission line 2, and the end of the inner support support frame 31 located at the top of the packaging box transmission line 2 is the inner support discharge end. One end of the inner support support frame...

Embodiment 2

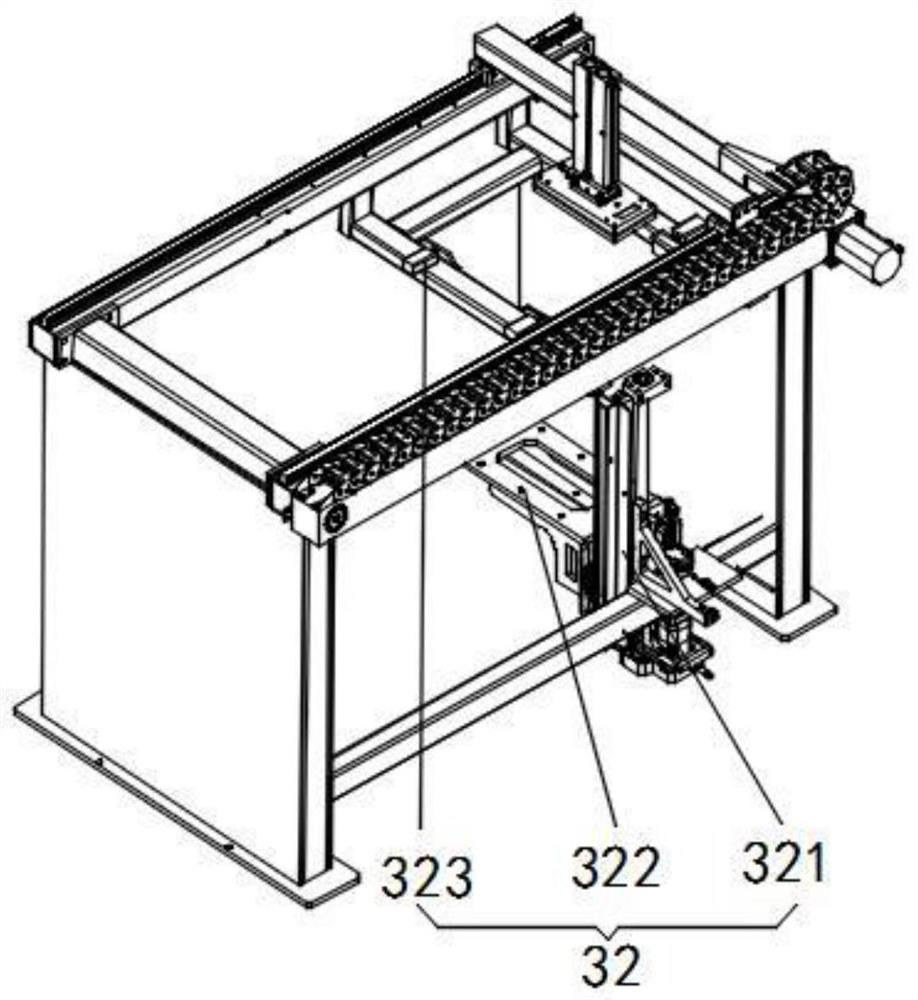

[0049] This embodiment is further optimized on the basis of Embodiment 1, such as image 3 As shown, the inner support lifting and loading device 32 includes an inner support lifting device 321, an inner support carrier 322, and an inner support layering device 323, and the inner support lifting device 321 is arranged in the vertical direction of the inner support The inner support loading end of the support frame 31 is provided with an inner support carrier 322 on the lifting end of the inner support jacking device 321 , and an inner support layering device 323 is provided on the top of the inner support jacking device 321 .

[0050] The inner support carrier 322 is directly connected to the lifting end of the inner support lifting device 321 through connecting bolts, and a plurality of inner supports are stacked on the inner support carrier 322 . The inner support lifting device 321 drives the stacked inner supports to move upward. When the top inner support moves to the fee...

Embodiment 3

[0066] This embodiment is further optimized on the basis of the above-mentioned embodiment 1 or 2. Between the outlet end of the gas meter three-axis pick-up device 4 and the box labeling machine 8, along the transmission direction, a partition placing device 5 and Protective cover mounting device 6.

[0067] further, as Image 6 As shown, the partition placement device 5 includes a shuttle material support 51, and a paper partition shuttle material slit 52 is arranged on the shuttle material support 51 parallel to the transmission direction, and the shuttle material support 51 is located on the paper partition shuttle material. The two ends of the slit 52 are respectively slidably provided with clipping supports 53; between the clipping end faces of the clipping supports 53 at both ends, a partition shuttle wheel group 54 is rotated parallel to the paper partition shuttle slit 52. A pushing device 57 is arranged between the clipping end faces of the clipping support 53 perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com