Ultrafiltration membrane sewage treatment equipment based on non-compact filter element

A sewage treatment equipment, compact technology, applied in osmosis/dialysis water/sewage treatment, sustainable biological treatment, membrane technology, etc., can solve the problem of high frequency of filter element fouling, poor backwash effect, and reduced filtration effect and other problems to achieve the effect of improving efficiency, improving backwashing efficiency and backwashing effect, and improving filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

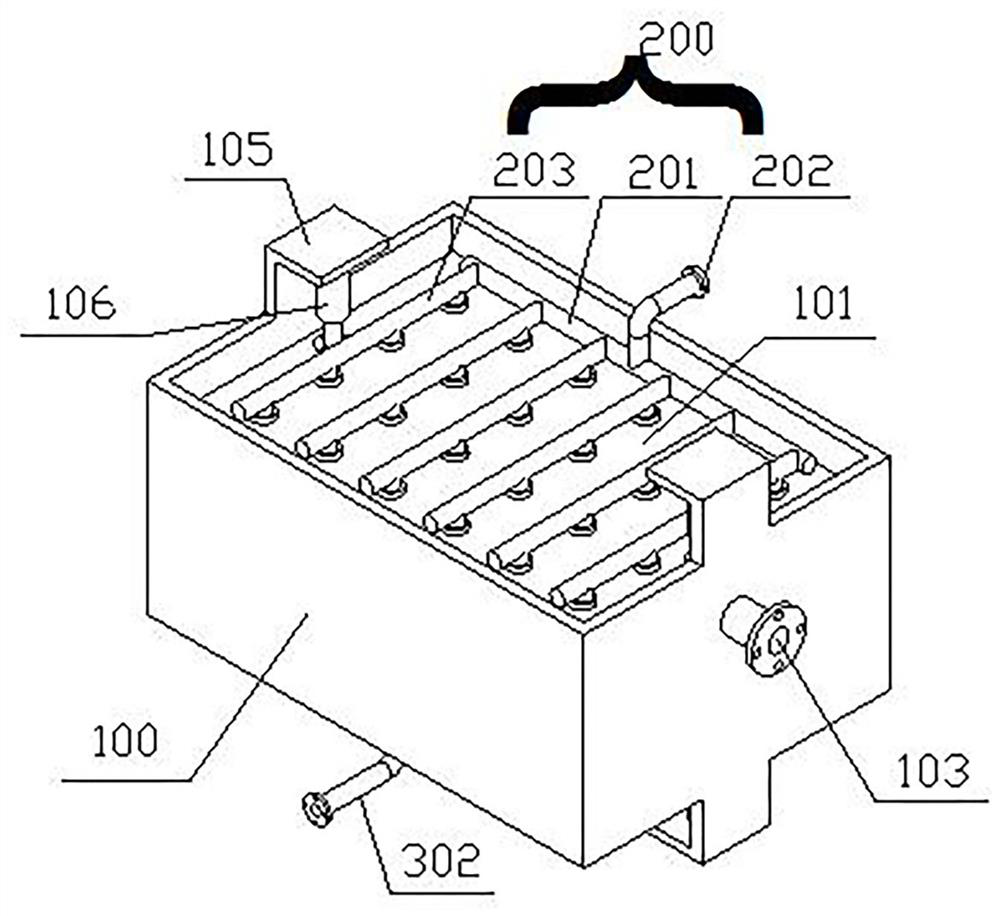

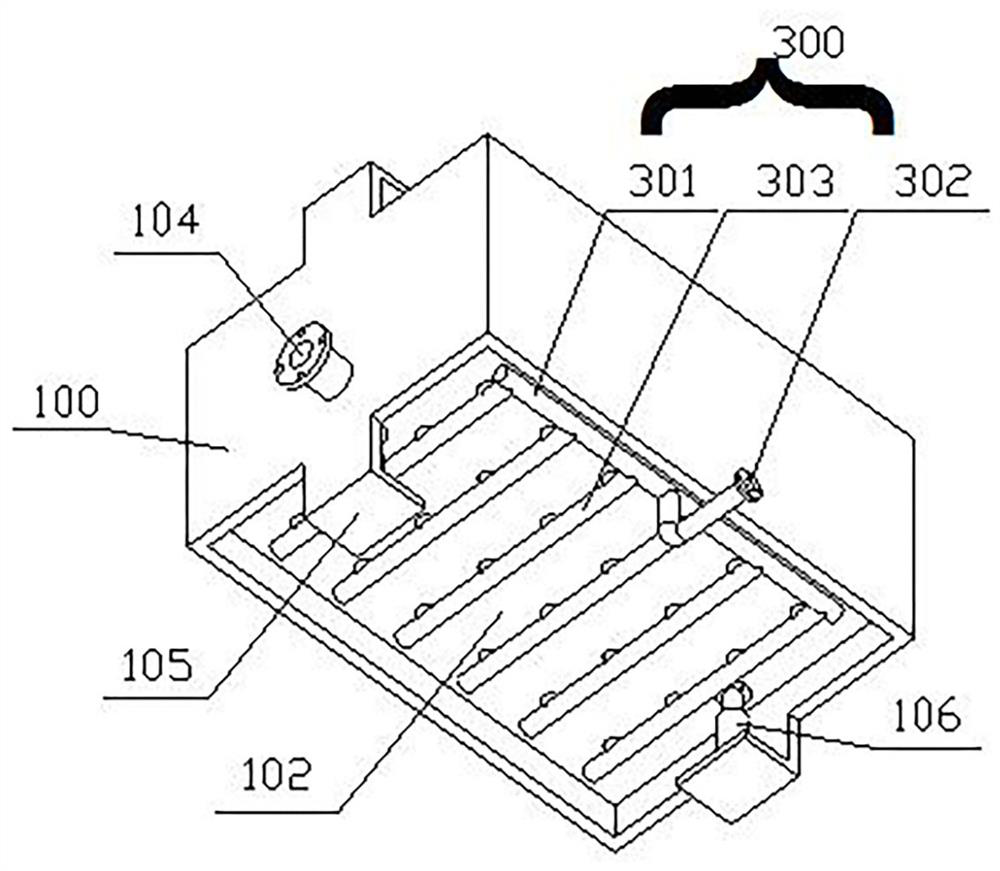

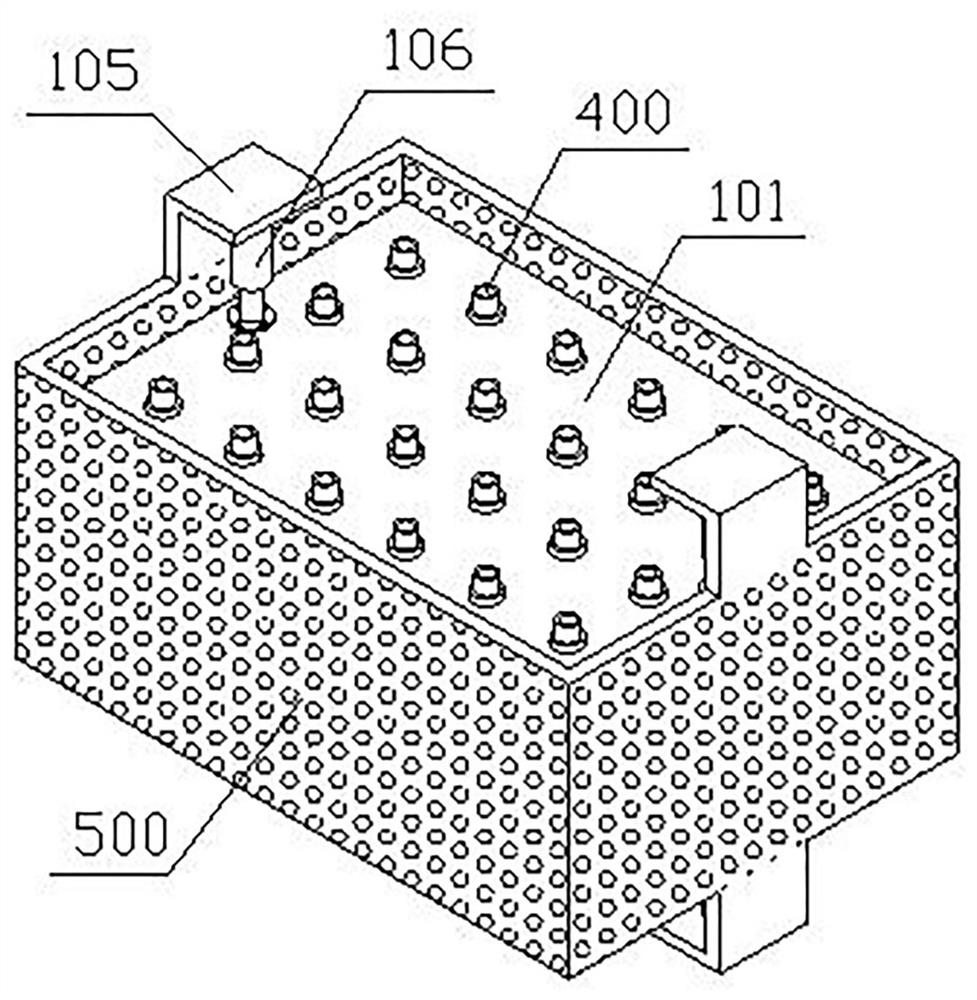

[0037] The invention discloses an ultrafiltration membrane sewage treatment equipment based on a non-compact filter element, such as Figure 1-4As shown, it includes an assembly box, a water outlet piping system 200, a backwash piping system 300 and multiple rows of non-compact filter elements 400, wherein the multiple rows of non-compact filter elements 400 are arranged side by side to form a filtering mechanism. The water outlet pipe system 200 of the present invention includes a water outlet main pipe 201, a water outlet joint 202 and a plurality of water outlet branch pipes 203. The outlet ends of each row of non-compact filter elements 400 are respectively connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com