Fabricated anti-seismic structure of composite floor slab and prefabricated wall and construction method of fabricated anti-seismic structure

A technology of superimposing floor slabs and prefabricated walls, which is applied to floors, building structures, walls, etc., can solve problems such as prone to collapse, and achieve the effect of avoiding cracking or tipping, avoiding tipping, and achieving reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

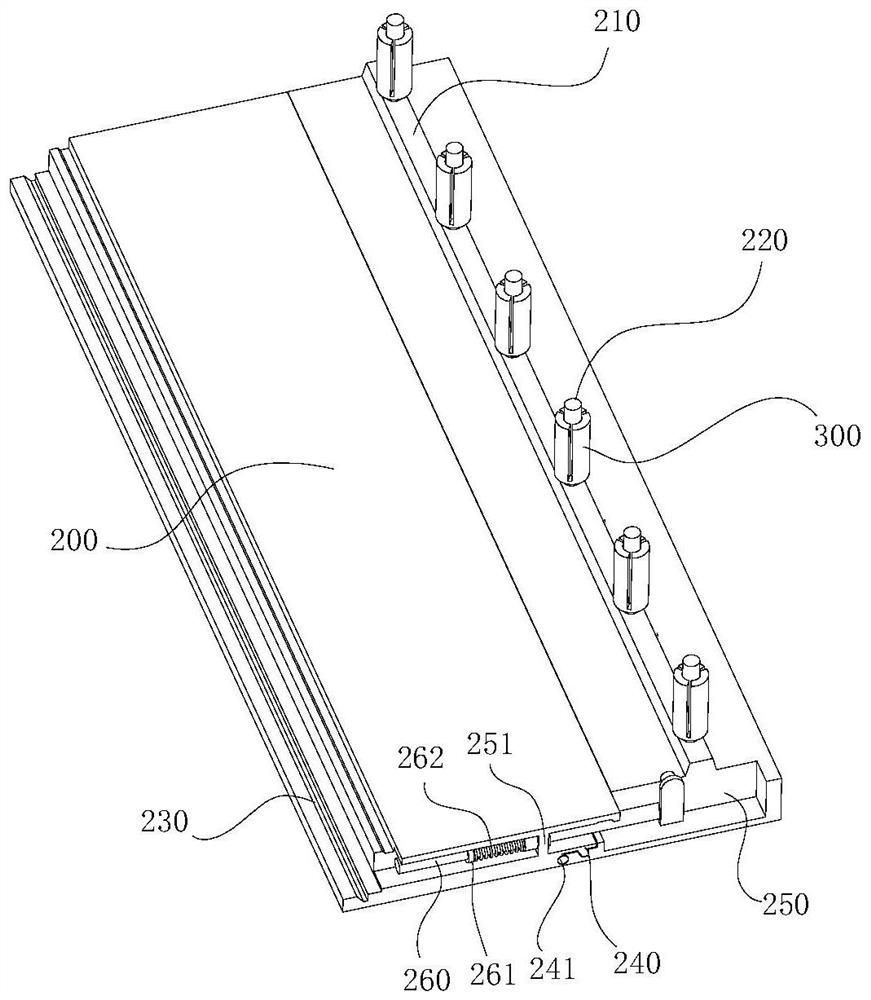

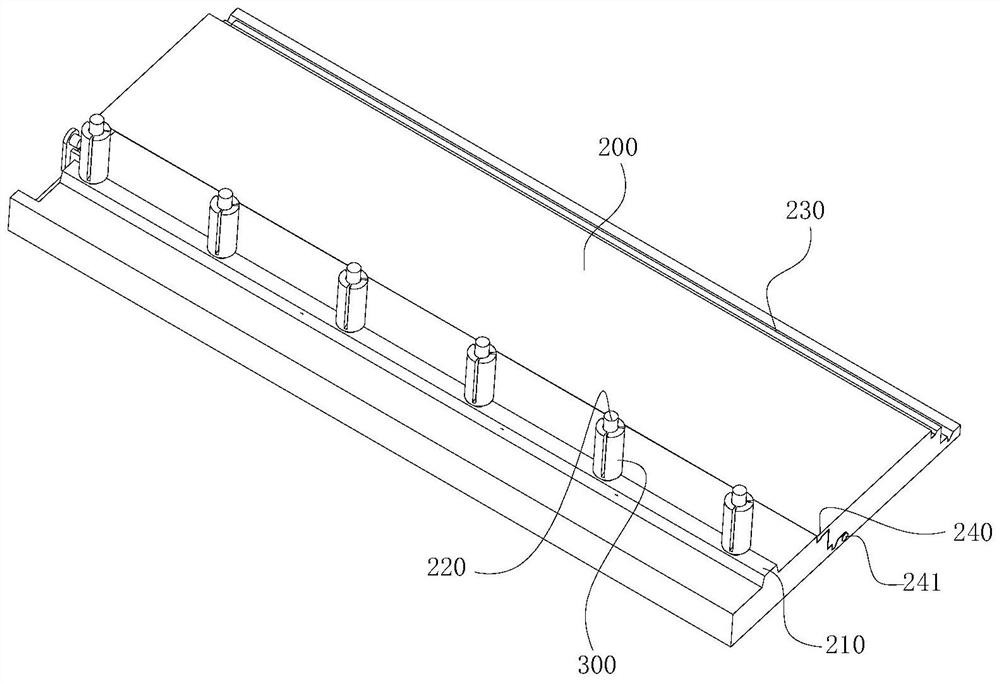

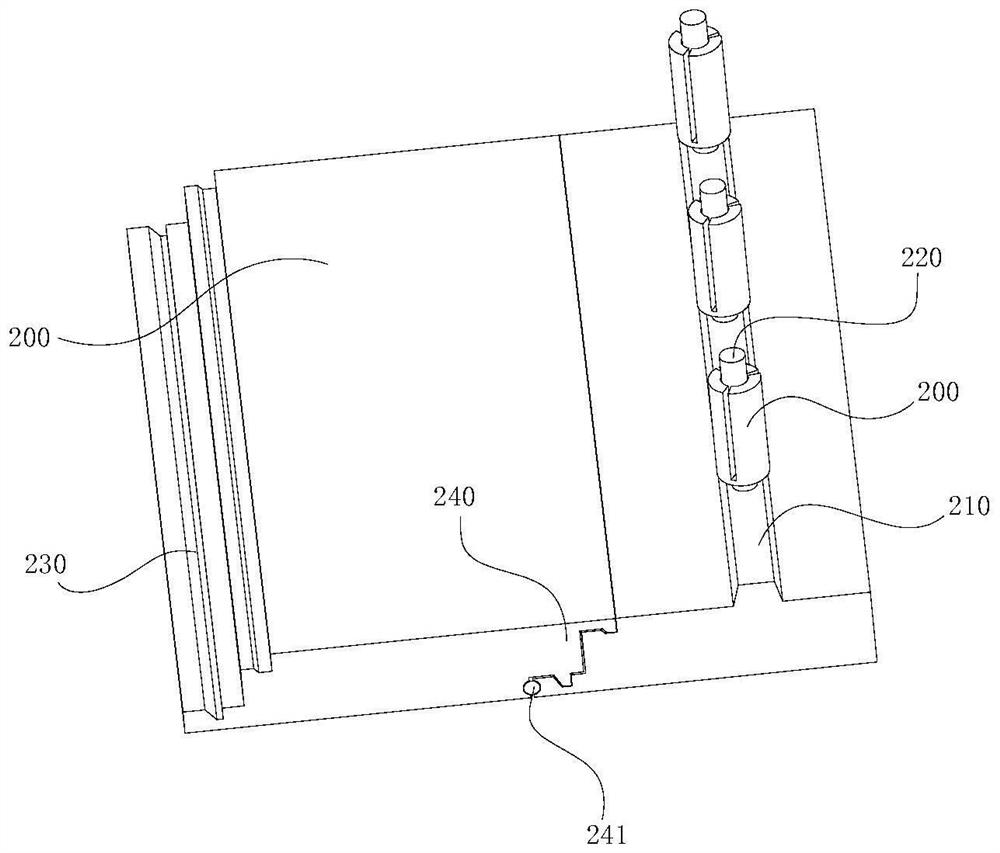

[0043] combined with Figure 1 to Figure 6 , the prefabricated seismic structure of the laminated floor slab and the prefabricated wall body in this embodiment includes a matching wall body 100 and a laminated floor slab 200. The multiple laminated floor slabs 200 are spliced together to form the floor slab of the entire prefabricated building. A movable gap is set between one end of the wall body 100 and the superimposed floor slab 200, and a buffer sleeve 300 is arranged in the movable gap. After the floor slab 200 is produced in the factory according to the designed size, a buffer sleeve 300 is arranged in the movable gap between the wall body 100 and the superimposed floor slab 200. The buffer sleeve 300 can effectively absorb the impact force generated by the lateral swing of the wall body 100, so that the wall body 100 can present a certain intensity of shaking based on the horizontal plane, so as to effectively absorb energy, thereby achieving the purpose of anti-vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com