Continuous rotary motor blade and stator friction pair with surface texture

A rotary motor and surface texture technology, which is applied in the field of hydraulic transmission, can solve the problems of small friction coefficient and wear amount, reduce the friction characteristics between motor friction pairs, etc., and achieve the goals of improving wear resistance, reducing friction, and reducing friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

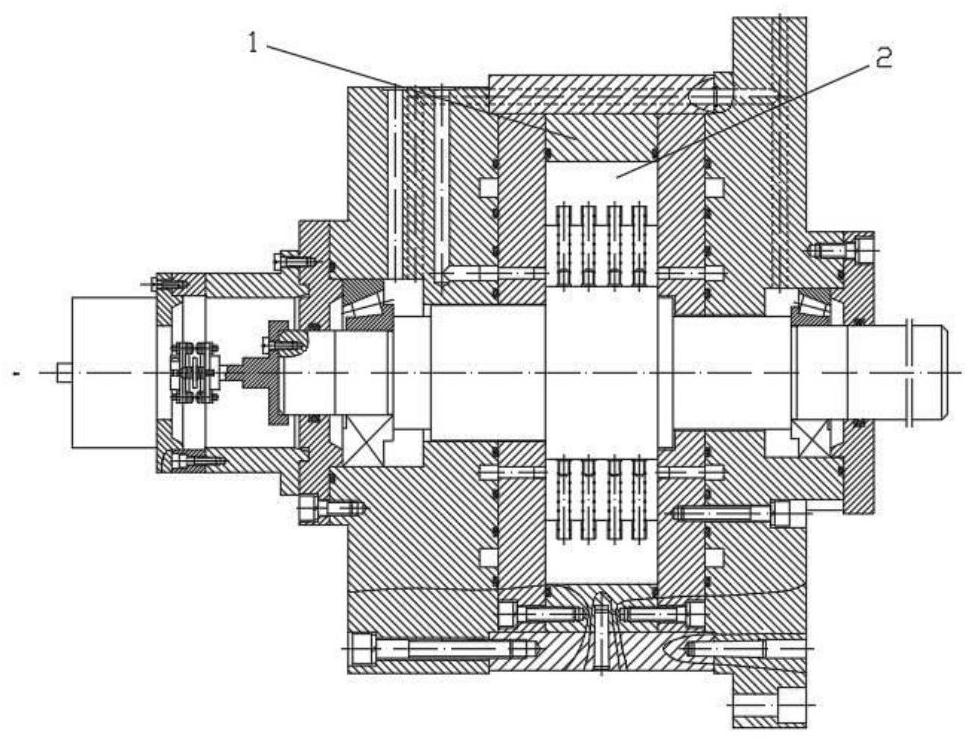

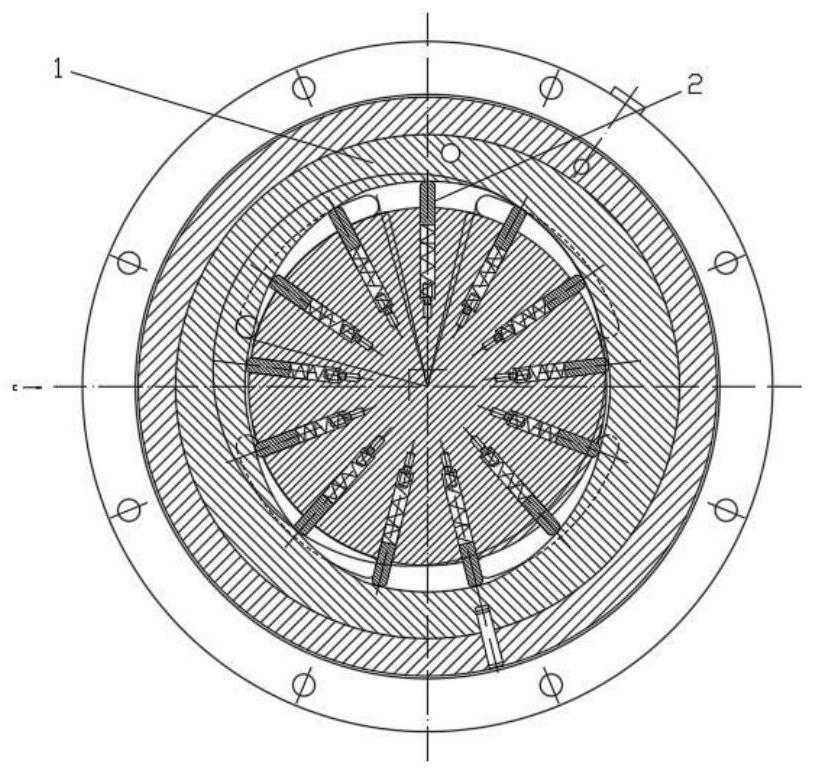

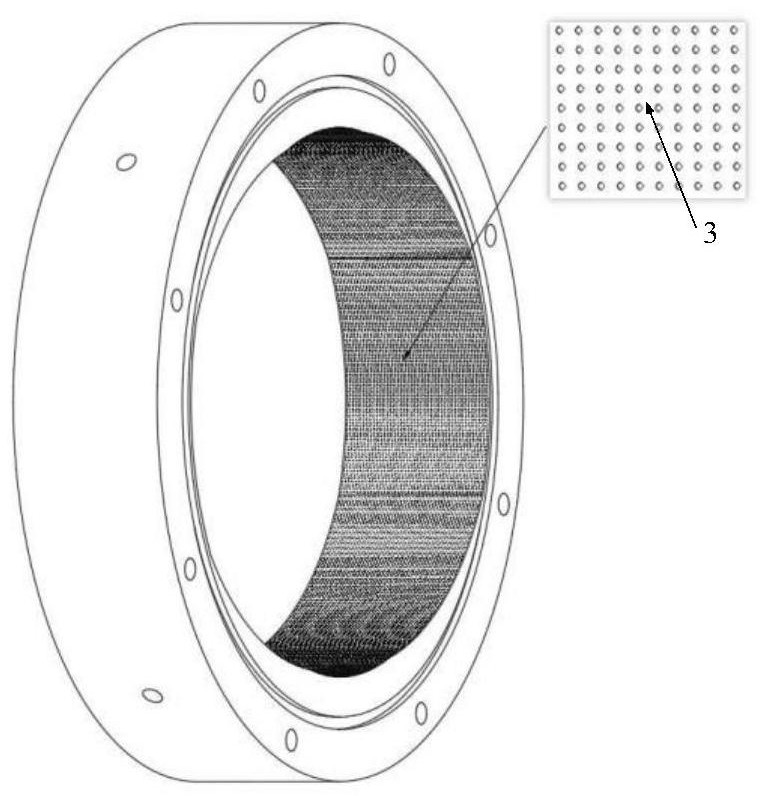

[0025] exist figure 1 , figure 2 , image 3 and Figure 4 In the shown schematic diagram of a continuous rotary motor blade and stator friction pair with surface texture, the present invention includes a blade and stator friction pair composed of the inner surface of the stator 1 and the top of the blade 2, and the inner surface of the stator 1 of the friction pair is rubbed. Both the surface and the friction surface of the top of the blade 2 are provided with a number of pit textured units 3 to form a non-smooth surface morphology, that is, the friction surface of the friction pair with surface texture is the inner surface of the stator 1 and the top of the blade 2 two. friction surface.

[0026] The depth of the dimple texture unit body 3 is 10-35 μm, and its opening area on the friction surface is 7854-196350 μm 2 , the area ratios of the pit texture unit 3 are 10%, 20%, 30%, 40%, 50% and 60%.

[0027] The above-mentioned pit texture unit bodies 3 are evenly and regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com