Medicine quality inspection sampling device with pressurizing and discharging functions

A drug quality, inspection and sampling technology, applied in the direction of sampling devices, etc., can solve problems such as easy pollution of drug liquid, influence of drug liquid volume, and deviation of drug liquid volume, so as to avoid excessive residue, good quantitative effect, convenient cleaning and Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

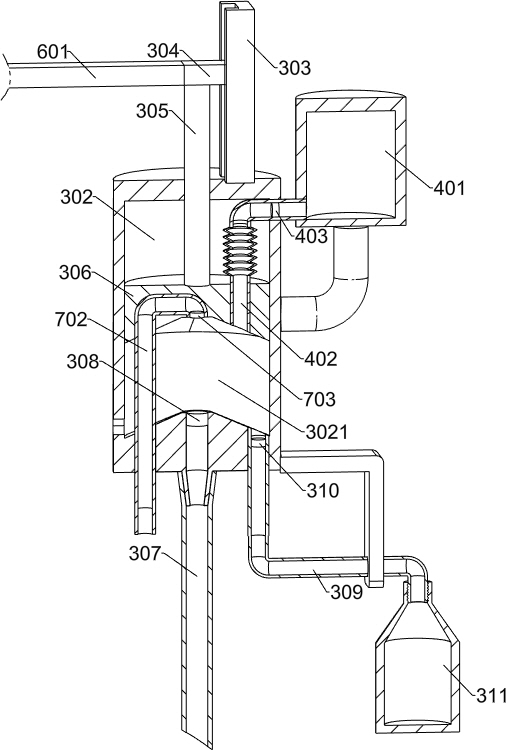

[0029] A sampling device for drug quality inspection with pressurized discharge function, such as figure 1 As shown, it includes an operation table 1, a console 2 is arranged on the front part of the left side of the upper surface of the operation table 1, a limit hole for limiting the position of the medicine bottle is opened on the right part of the upper surface of the operation table 1, and a limit hole on the operation table 1 is provided. A medicine bottle is placed in the position hole, a sampling mechanism 3 for sampling the medicinal liquid in the medicine bottle is arranged at the rear of the upper surface of the operating table 1, and a cleaning assembly for cleaning the sampling mechanism 3 after sampling is arranged on the right side of the upper part of the sampling mechanism 3 4. The left side of the upper part of the sampling mechanism 3 is provided with a pressurized discharge mechanism 5 for assisting the discharge of the medicinal liquid in the sampling mecha...

Embodiment 2

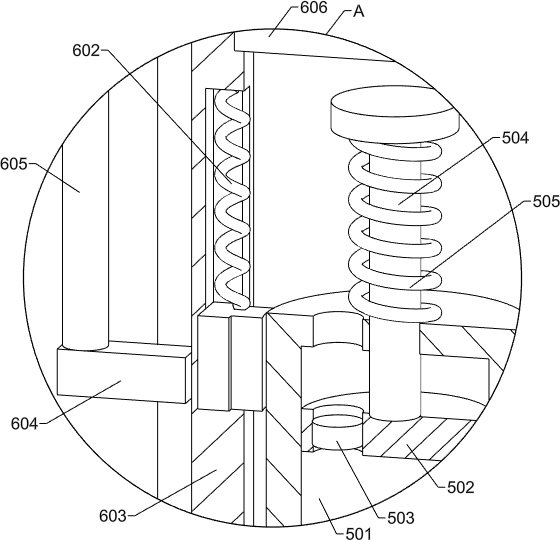

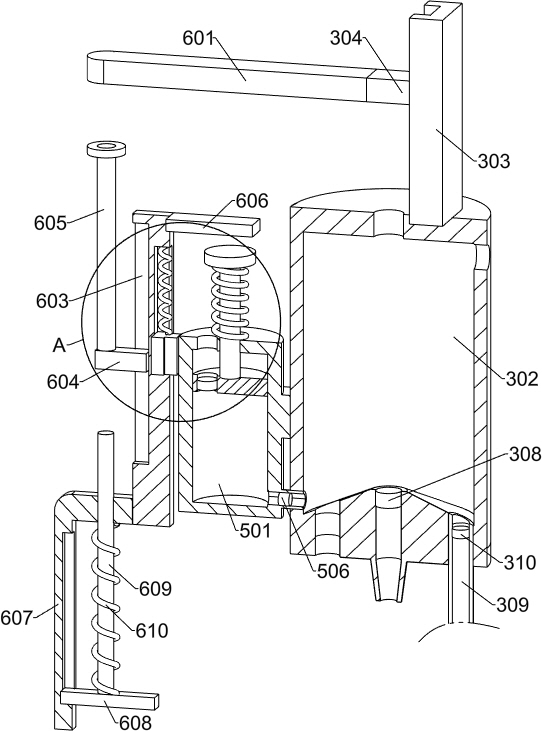

[0032] On the basis of Example 1, as figure 2 and image 3 As shown, the sampling mechanism 3 includes a hydraulic push rod 301, the hydraulic push rod 301 is electrically connected with the console 2, the telescopic end of the hydraulic push rod 301 is fixedly connected with a sampling cylinder 302 through a support plate, and the right part of the upper surface of the sampling cylinder 302 is welded There is a first electric sliding rail 303, a first electric sliding block 304 is slidably arranged on the first electric sliding rail 303, the first electric sliding block 304 is electrically connected with the console 2, and the lower part of the first electric sliding block 304 is fixedly connected with a first electric sliding block 304. A sliding rod 305, the first sliding rod 305 penetrates the upper part of the sampling cylinder 302 and is slidably connected with it. The sampling cylinder 302 is slidably provided with a sampling piston 306, and a sampling cavity 3021 is f...

Embodiment 3

[0043] On the basis of Example 2, as Figure 8 and Figure 9As shown, also includes a disinfection mechanism 8, the disinfection mechanism 8 is arranged in the lower part of the sampling mechanism 3, the disinfection mechanism 8 is used for the disinfection of the sampling mechanism 3, the disinfection mechanism 8 is electrically connected with the console 2, and the disinfection mechanism 8 includes an L-shaped limiter. The position plate 801, the L-shaped limit plate 801 is welded on the left part of the upper surface of the console 1, the right side of the upper part of the L-shaped limit plate 801 is a circular ring, and the right side of the upper part of the L-shaped limit plate 801 is rotated and provided with a rotating sleeve Tube 802, the upper part of the operating table 1 is provided with two through grooves, the two through grooves on the operating table 1 are slidably provided with a U-shaped rod 803, the right part of the U-shaped rod 803 is provided with a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com