Novel anti-missing signal acquisition method for rotary machinery

A signal acquisition and rotating machinery technology, applied in computer parts, motor generator testing, comprehensive factory control, etc., can solve problems such as inapplicability to rotating machinery, a small number of indicators, rigid acquisition strategies, etc., to avoid missed sampling, The effect of precise collection

Pending Publication Date: 2022-08-09

台州守敬应用科技研究院有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the strategy of continuous collection or fixed-point collection is usually adopted for signal collection of mechanical structures; continuous collection means continuous collection of vibration data, and fixed-point collection means collection at fixed time intervals; this kind of collection strategy is relatively rigid, and the amount of data collected It is large but contains low amount of effective information, and it is easy to miss the data at the time of failure, so it is not suitable for rotating machinery; in order to solve the above problems, practitioners in the industrial field have used vibration signal indicators as the standard for signal trigger collection, but the indicators used are generalized The ability is poor and the number of indicators is small, the effect of trigger collection is poor, and it cannot be applied in multiple industrial scenarios

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

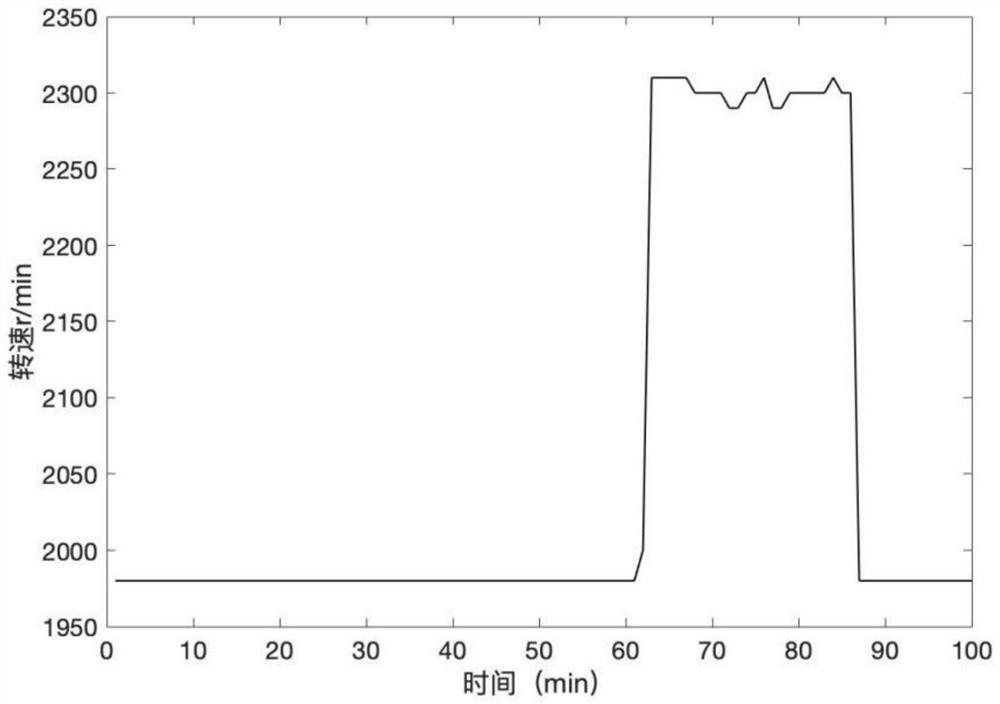

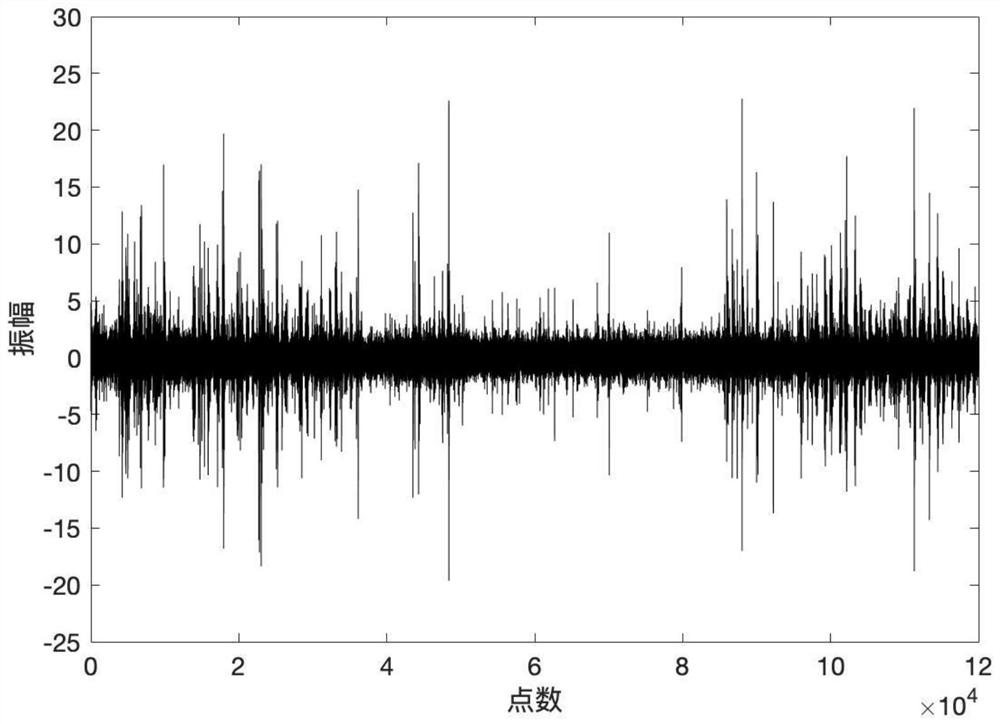

[0038] Taking a company's full life cycle motor bearing as an example, the effectiveness of the patented method of the present invention is verified. The duration of this full life cycle experiment is one month. The motor bearing will be prefabricated with minor inner ring faults and run uninterruptedly on the test bench under actual working conditions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

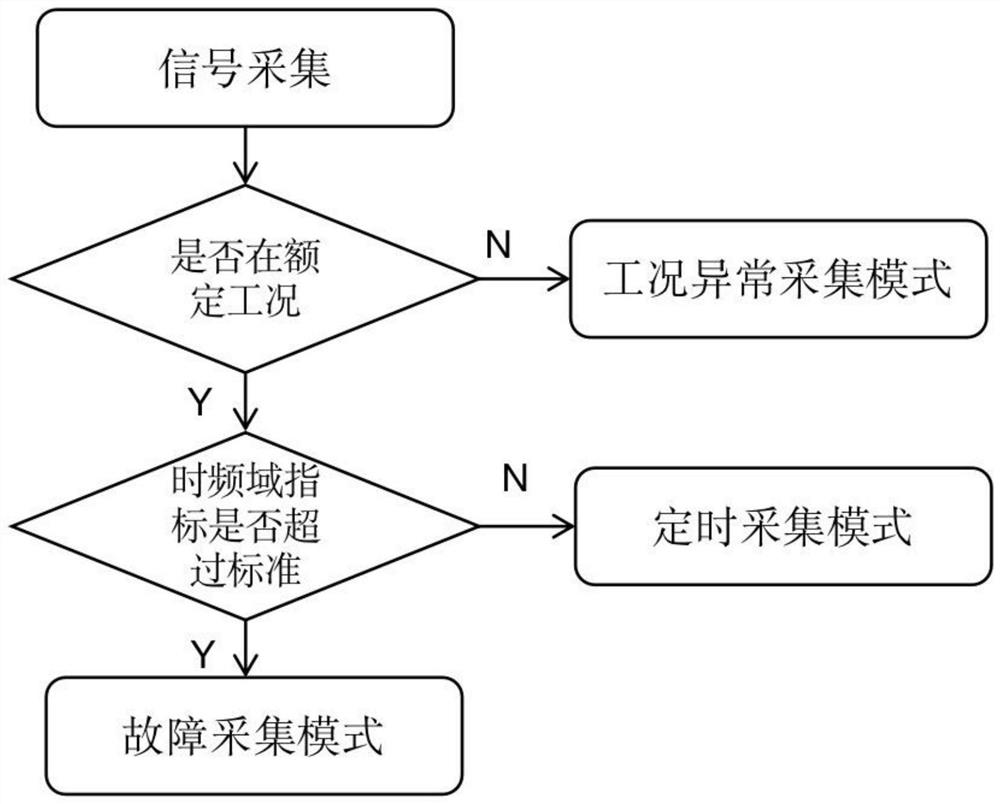

The invention relates to a novel anti-missed-sampling signal acquisition method for a rotary machine, which comprises three anti-missed-sampling logics which are a fault acquisition mode, an abnormal working condition acquisition mode and a timing acquisition mode in sequence from high to low according to priority ranking, and is controllable in signal sampling frequency and capable of sampling in real time. According to the invention, triggering acquisition of signals is carried out through multiple index parameters, and three acquisition modes, namely a fault acquisition mode, a working condition abnormity acquisition mode and a timing acquisition mode, are established; different types of index parameters are used for constructing an evaluation index library, seven dimensioned indexes and seven dimensionless indexes are adopted in a fault acquisition mode, multiple algorithm judgment strategies are formulated according to actual working conditions, and an optimal acquisition strategy is formulated, so that accurate acquisition of signals at a fault moment is realized, and missing acquisition of fault signals is avoided to the greatest extent.

Description

technical field [0001] The invention relates to the field of signal collection, in particular to a novel leak-proof signal collection method for rotating machinery. Background technique [0002] At present, the signal acquisition for mechanical structures usually adopts the strategy of continuous acquisition or fixed-point acquisition; continuous acquisition means continuous acquisition of vibration data, and fixed-point acquisition means acquisition at fixed time intervals; this type of acquisition strategy is relatively rigid, and the amount of data collected It is relatively large but contains a low amount of effective information, and it is easy to miss the data at the time of failure. It is not suitable for rotating machinery. In order to solve the above problems, practitioners in the industrial field have used vibration signal indicators as the standard to trigger signal acquisition, but the indicators used are generalized. The ability is poor, the number of indicators...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06K9/00G06K9/62G01D21/02G01R31/34

CPCG01D21/02G01R31/343G06F2218/12G06F18/2433Y02P90/02

Inventor 易永余蔡璇璇

Owner 台州守敬应用科技研究院有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com