Inflation switch device with temperature rise current exceeding 4000 A

A switchgear and current technology, applied in the setting of switchgear, cooling/ventilation of substation/switchgear, electrical components, etc., can solve the problem of affecting the stability and service life of switchgear, reducing the insulation of insulating parts, and increasing the degree of overheating and other issues, to achieve the effect of improving heat dissipation, prolonging service life, and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

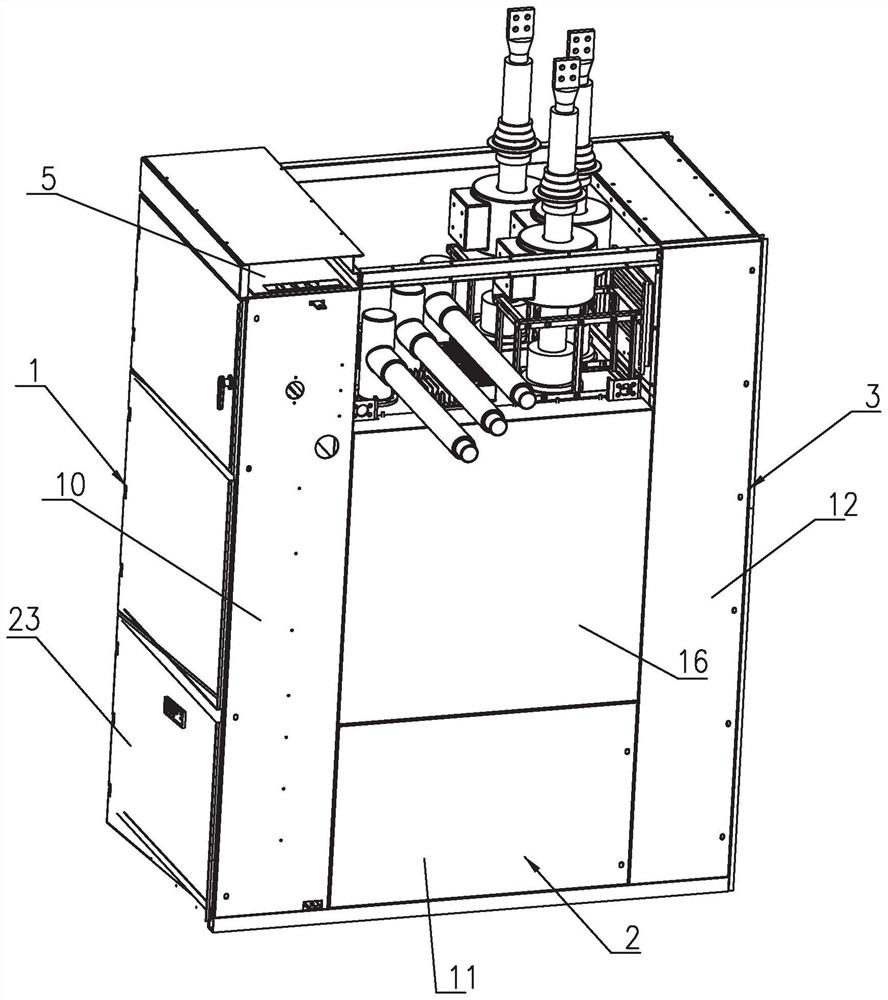

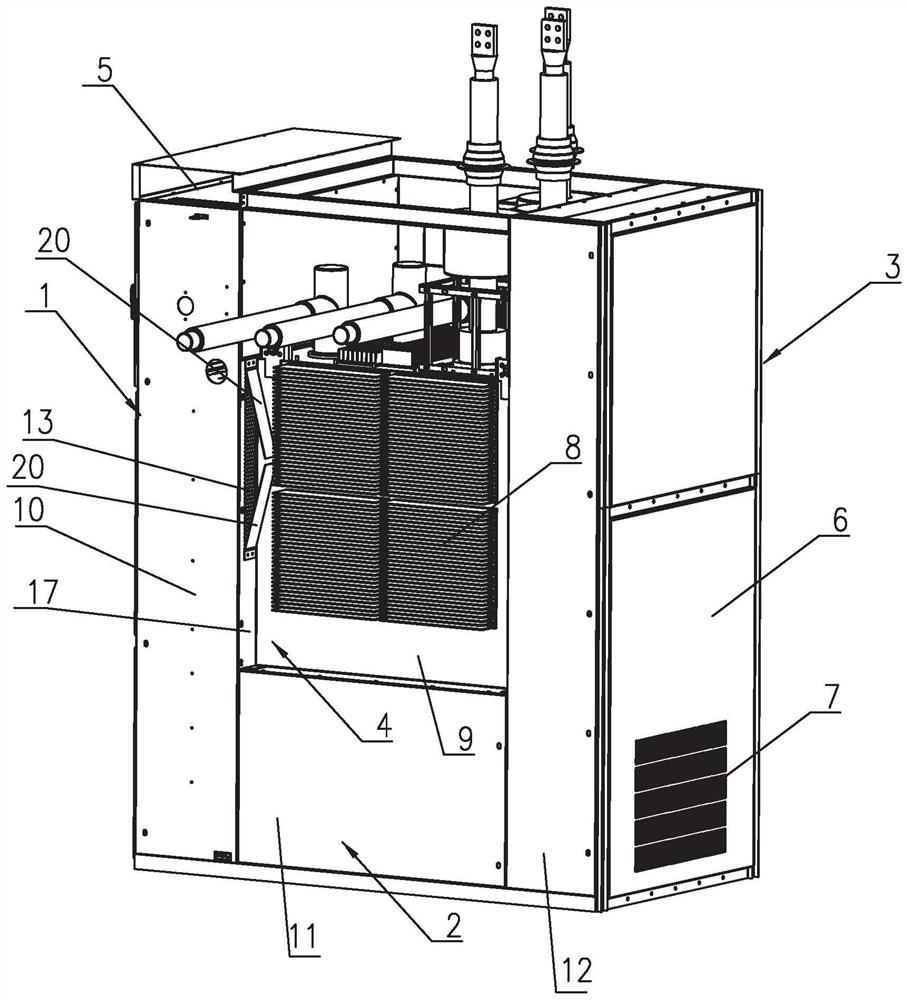

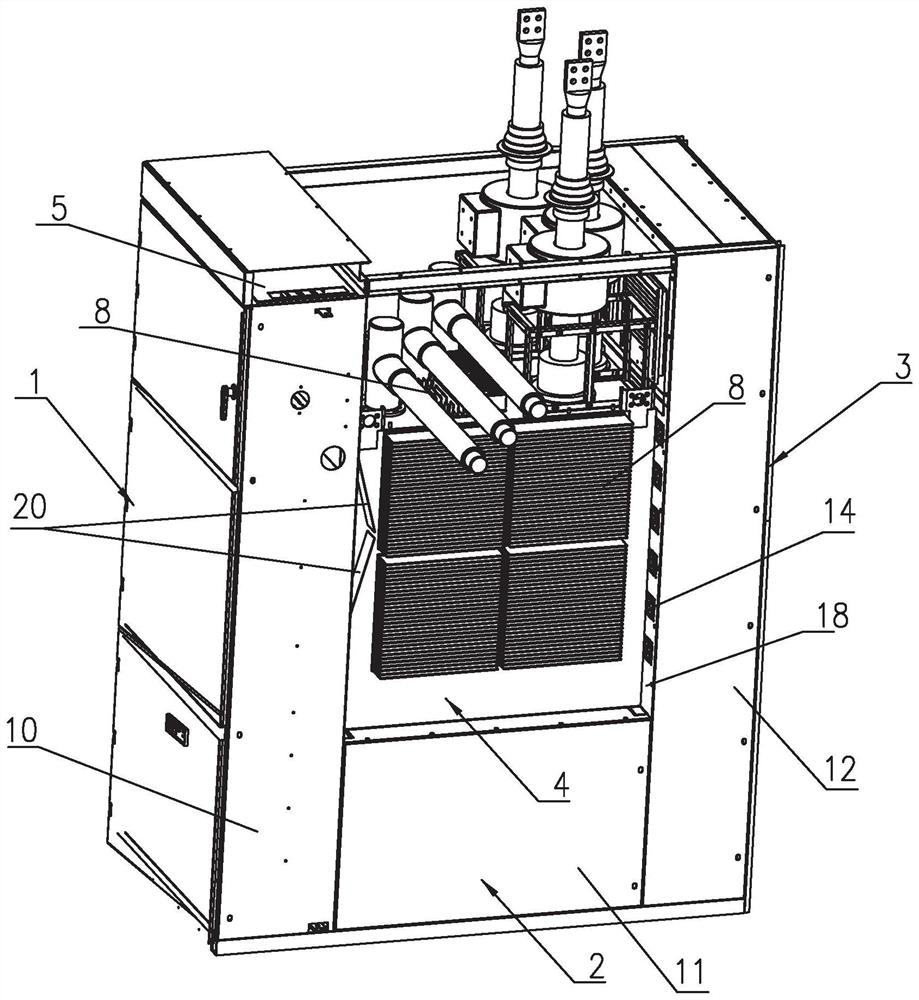

[0031] like Figures 1 to 7As shown, it is an inflatable switchgear of the present invention with a temperature rise current exceeding 4000A, including a front cabinet 1, a middle cabinet 2, a rear cabinet 3 and an air box 4, and the air box 4 is arranged on the top surface of the middle cabinet 2 and is located in the front cabinet. 1 and the rear cabinet 3, the top of the front cabinet 1 is provided with a first air inlet 5, the rear panel 6 of the rear cabinet 3 is provided with a second air inlet 7, and the second air inlet 7 is located at the bottom of the rear panel 6. , the two side panels 10 of the front cabinet 1, the two side panels 11 of the middle cabinet 2, the two side panels 12 of the rear cabinet 3 and the two side panels 9 of the air box 4 respectively have a height difference to form a recess. The two side plates 9 and the top plate are provided with heat dissipation plates 8. In this embodiment, studs are welded on the two side plates 9, and four aluminum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com