Mounting structure for magnetic head

A mounting structure and magnetic head technology, which is applied in the configuration/installation, fixed installation, magnetic recording, etc. of the recording head, which can solve the problems of increased number of parts, increased cost, troublesome thread cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation

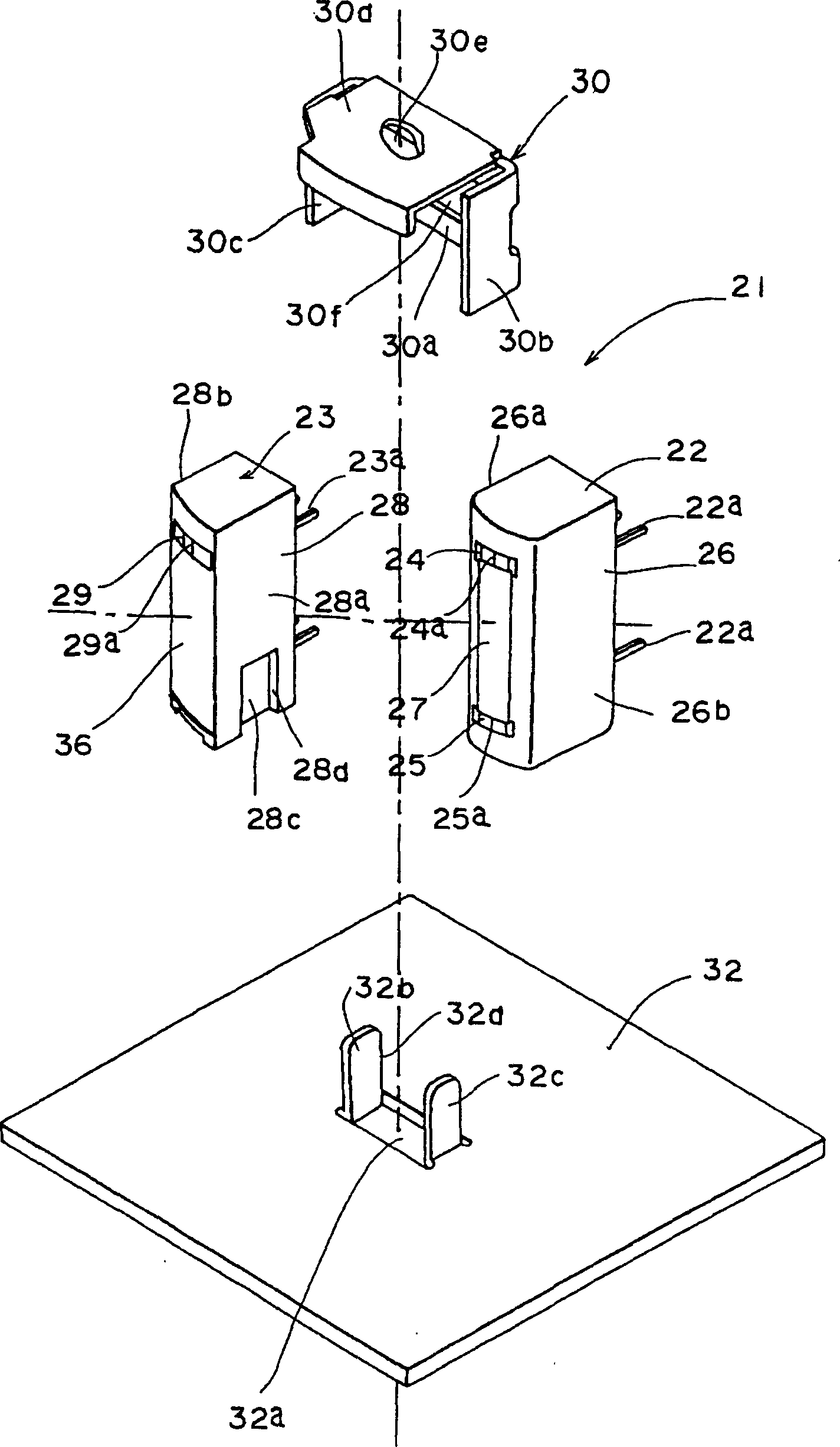

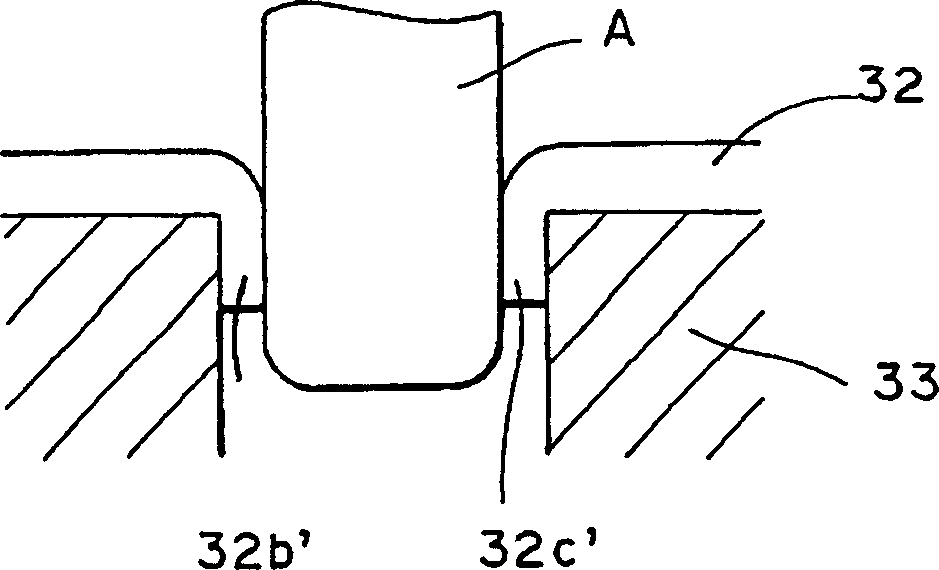

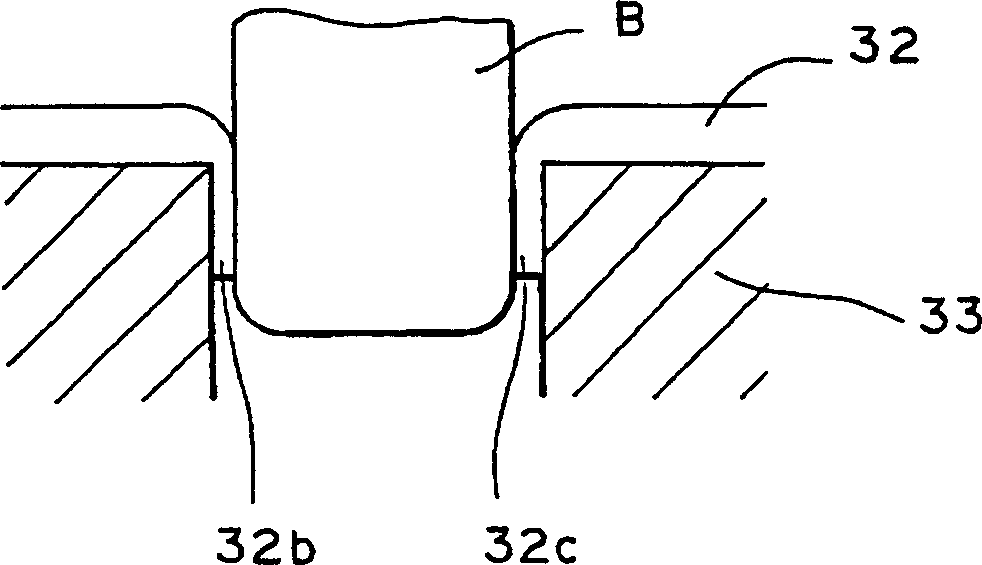

[0026] figure 1 To show an exploded perspective view of the main part of one embodiment of the magnetic head mounting structure of the present invention, by punching holes at given places on the mounting plate 32 made of rolled steel plate or the like, the opening 32a and the opposite sides at its two sides are made. A pair of bent pieces 32b, 32c. Such as Figure 2A , Figure 2B As shown, the forming method of the bent pieces 32b, 32c is to place the mounting plate 32 with a thickness of about 1.2mm on the metal mold 33, as the first process, in Figure 2A In this case, the mounting plate 32 is punched from above with a punch A, and a part thereof is bent to both sides to form bent portions 32b', 32c'. Then, as a second process, in Figure 2B In this process, the above-mentioned bent parts 32b', 32c' are drawn and thinned by using a punch B having a diameter larger than that of the punch A, and the bent parts 32b, 32c are formed to a thi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap