Suction cleaner for floor

A floor and suction inlet technology, which is applied in the direction of cleaning floors, household utensils, suction nozzles, etc., can solve the problems of smaller suction inlets, complicated turbine shapes, and inability to completely suck in dust, etc., to achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

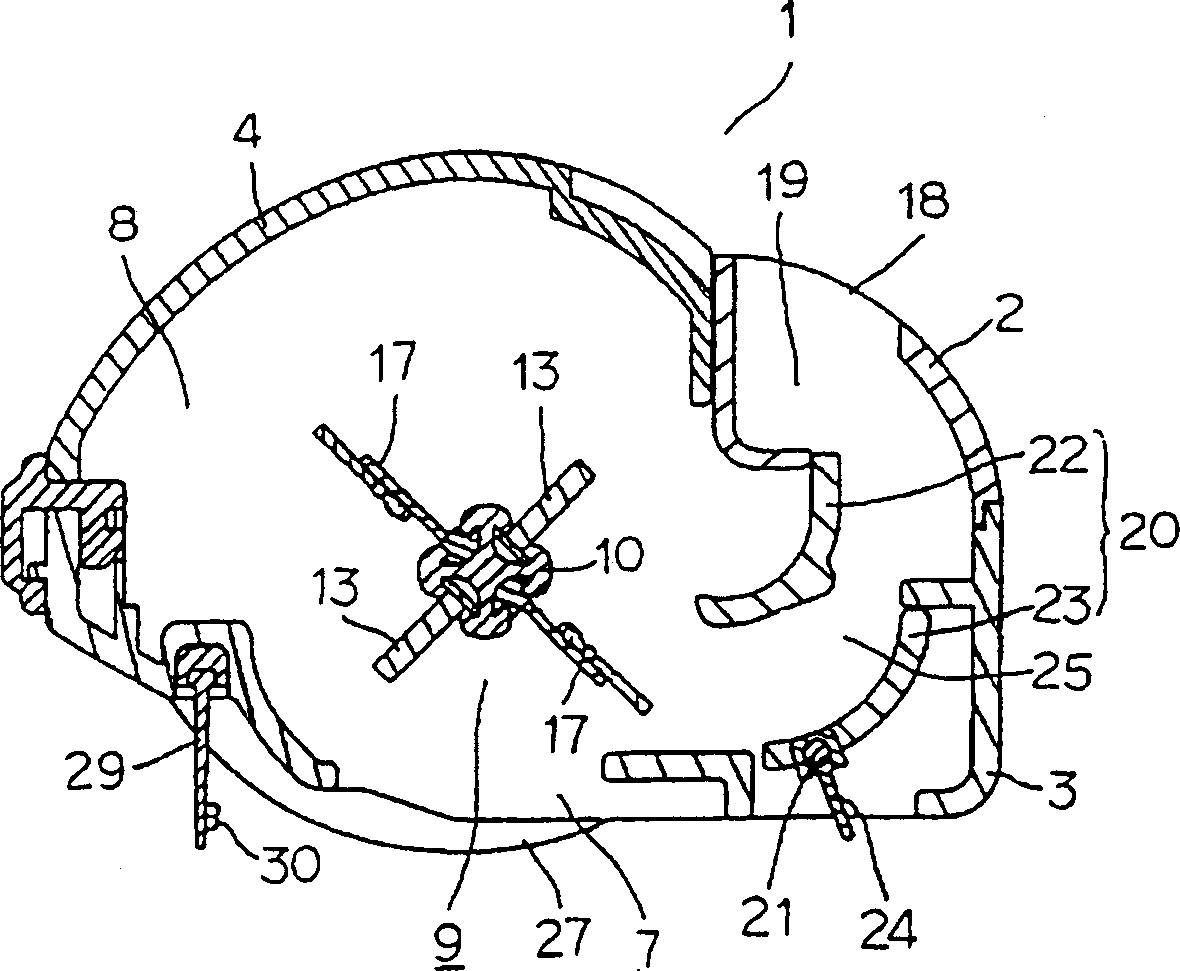

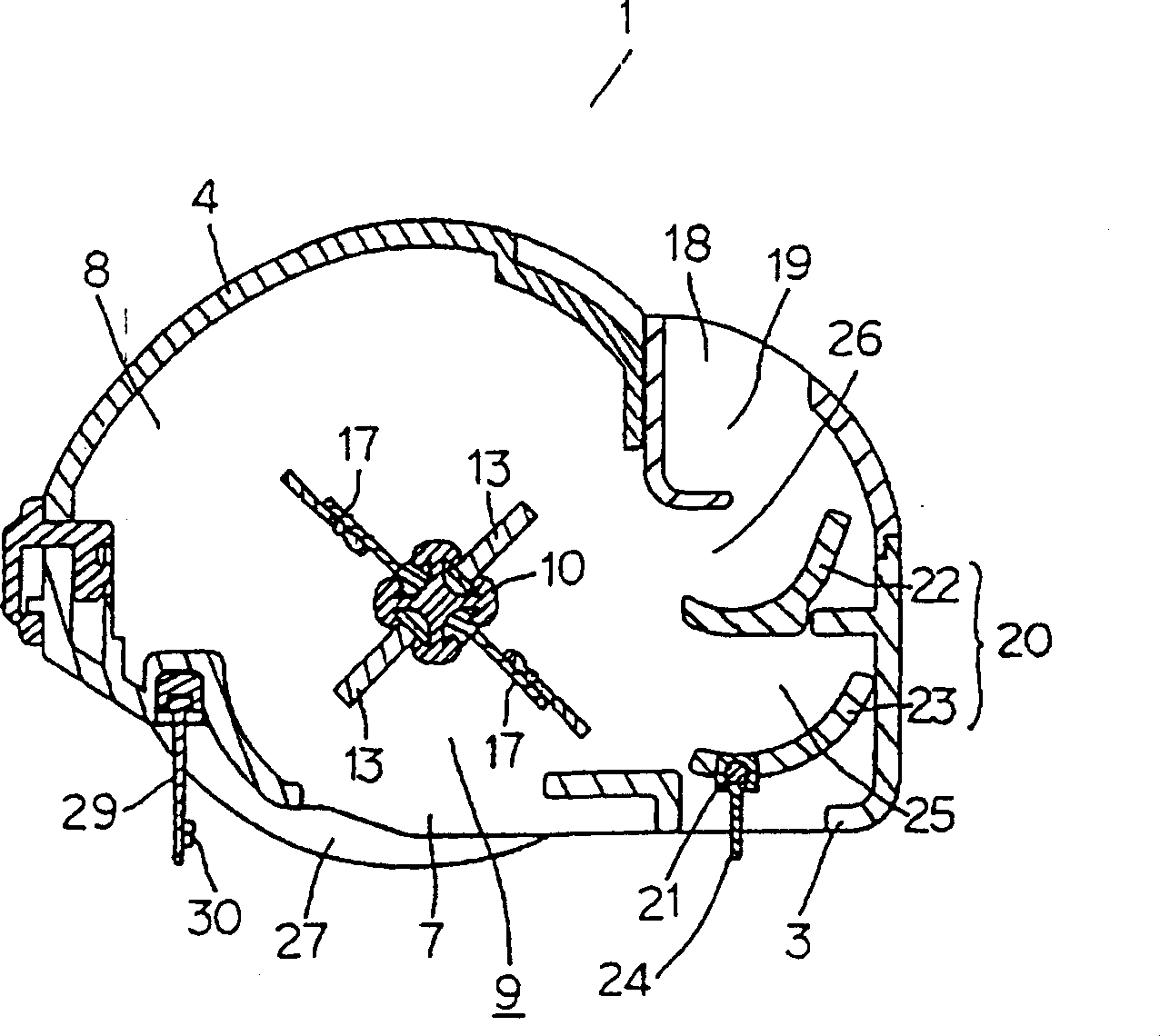

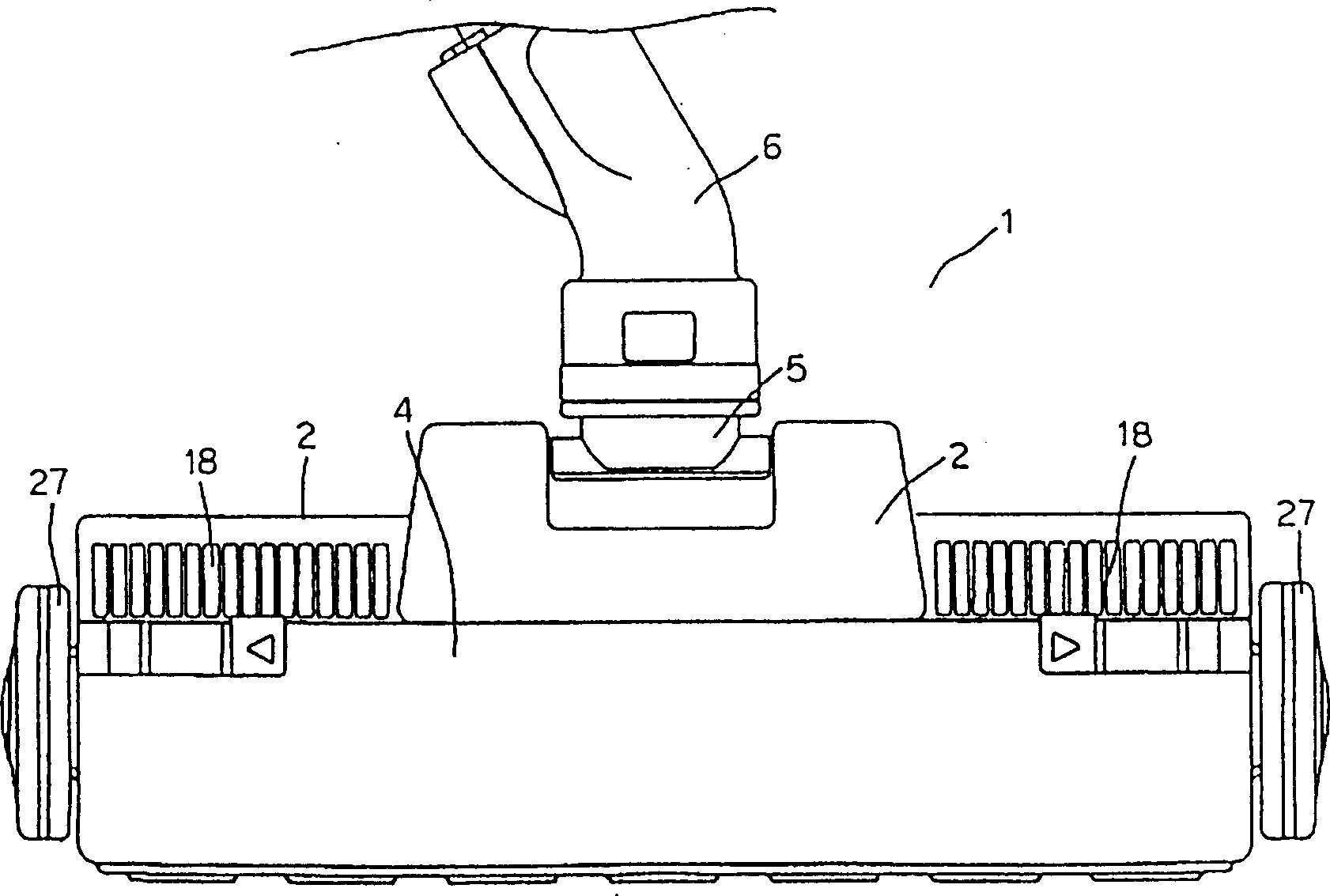

[0030] In the accompanying drawings, 1 is the main body of the vacuum cleaner, which is supported between the upper and lower shells 2 and 3 by the upper shell 2, the lower shell 3, and the cover body 4 that is fastened to the aforementioned upper shell 2 and the lower shell 3 and can be disassembled arbitrarily. And it consists of the rotating pipe 5 which can rotate arbitrarily in an up-down direction, and the connecting pipe 6 supported by this rotating pipe 5 and which can rotate arbitrarily. 7 is a suction port formed on the bottom surface of the aforementioned dust collector body 1, and 8 is a rotating brush storage chamber formed in the aforementioned dust collector body 1. 9 is a rotating brush that is housed in the rotating brush storage chamber 8 in a freely rotatable state facing the aforementioned suction port 7. The rubber-made first vane 13 attached to the helical groove 11 of the core 10, and a pair of second vanes 15 having a base 14 inserted into the helical g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com