Intelligent chip removal machine tool

A machine tool and chip removal technology, which is applied in the field of machine tools, can solve problems such as inability to recycle and blockage of cutting fluid pipes, and achieve the effects of protecting tools, prolonging service life, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

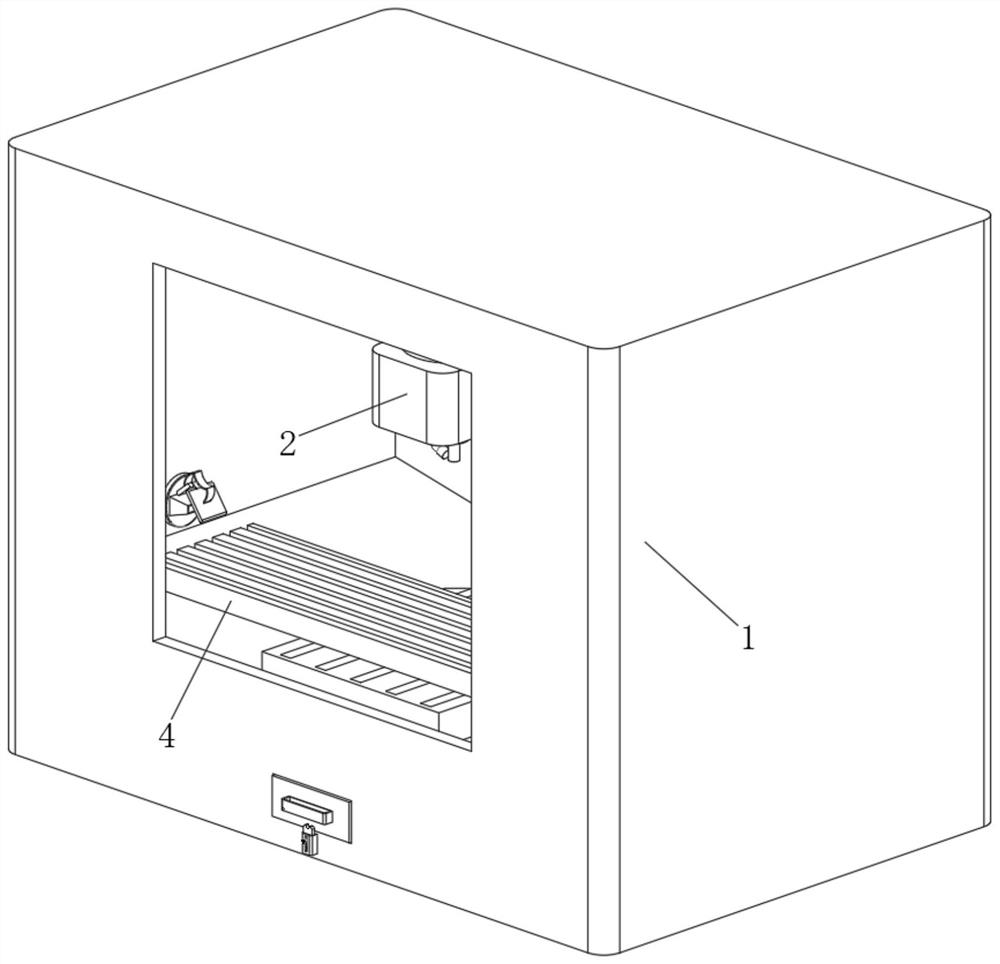

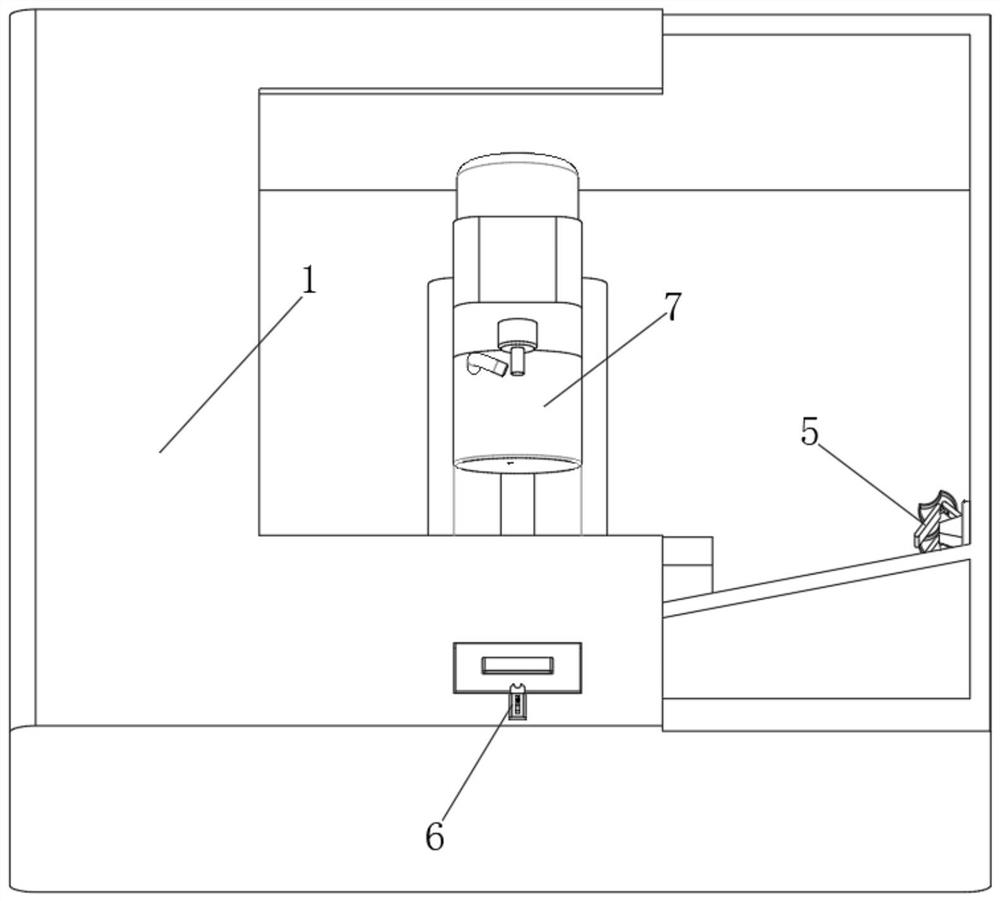

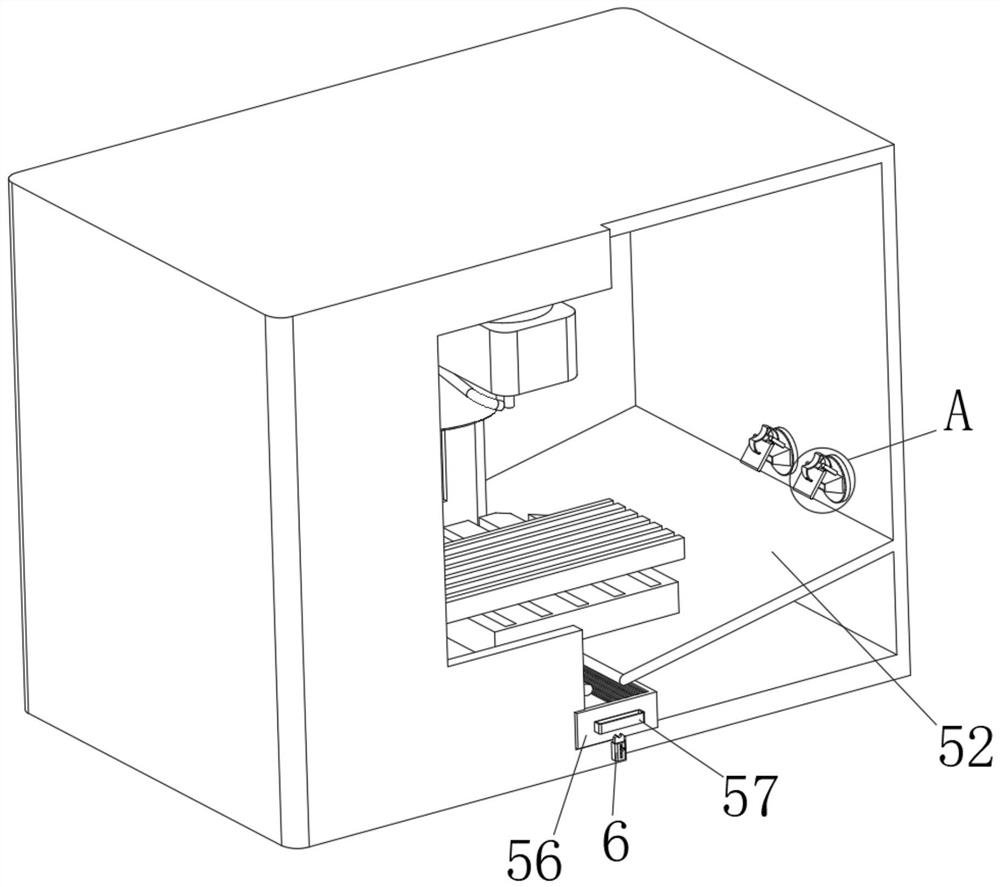

[0025] see Figure 1-6 As shown, an intelligent chip removal machine tool includes a machine tool shell 1, a machine tool body 2 is fixedly installed inside the machine tool shell 1, a tool 3 is arranged on the surface of the machine tool body 2, and the surface of the machine tool body 2 is fixedly installed Organic machine frame 4, the inside of described machine tool housing 1 is provided with collection mechanism 5, and described collection mechanism 5 comprises shower head 51, and described shower head 51 is fixedly connected with the inner wall of machine tool housing 1, and the quantity of described shower head 51 is four and It is symmetrically arranged in pairs, and the inner wall of the machine tool shell 1 is fixedly equipped with two symmetrically arranged guide plates 52, and the surface of the spray head 51 is fixedly installed with a mounting plate 53, and the inner wall of the mounting plate 53 is rotatably installed with The movable plate 54 has an elastic pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com