Intelligent driving device for oil field pumping unit

A driving device and pumping unit technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of low motor power factor, large waste of electric energy, low oil well output, etc., and reduce reactive power loss. , avoid downtime and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

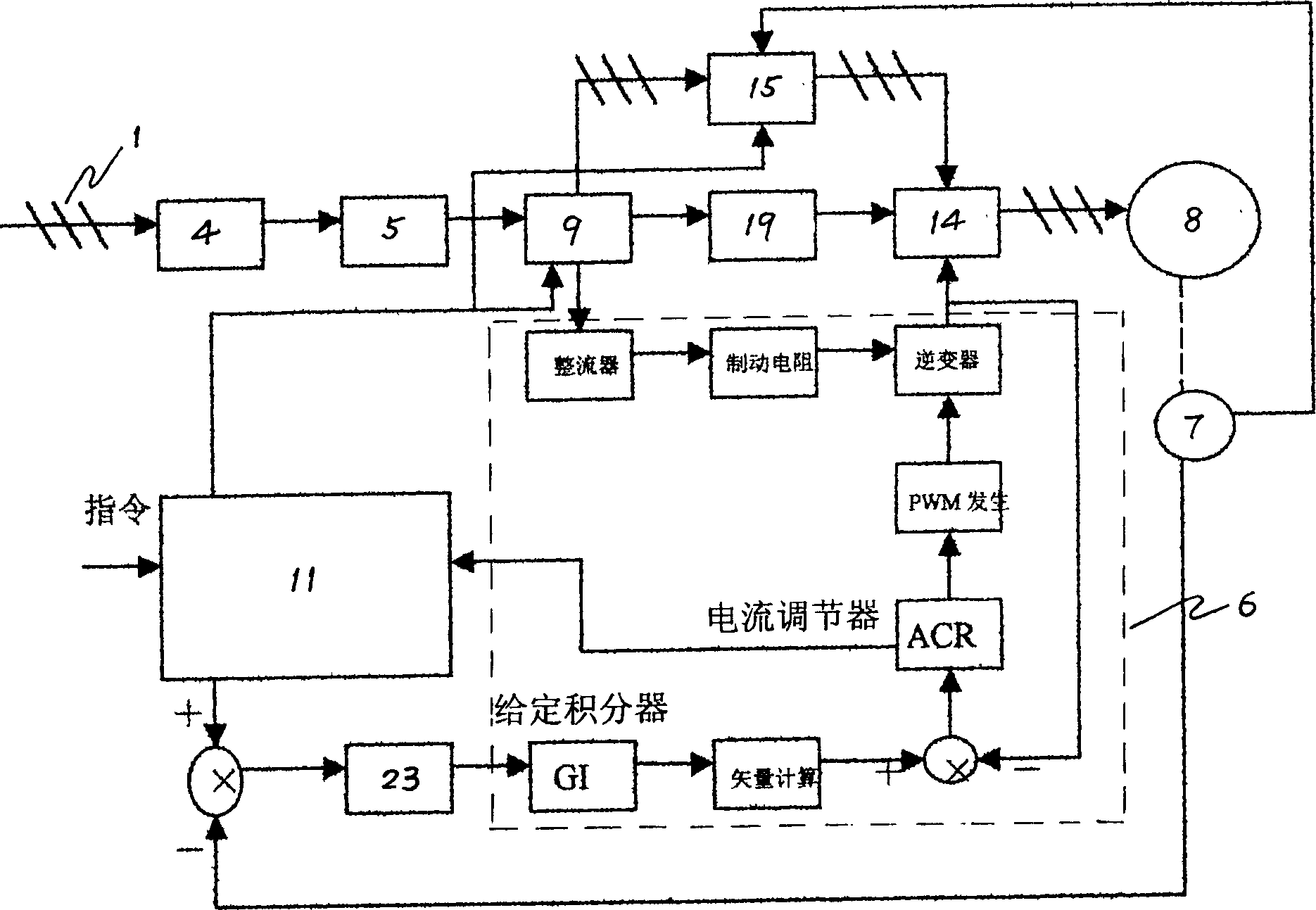

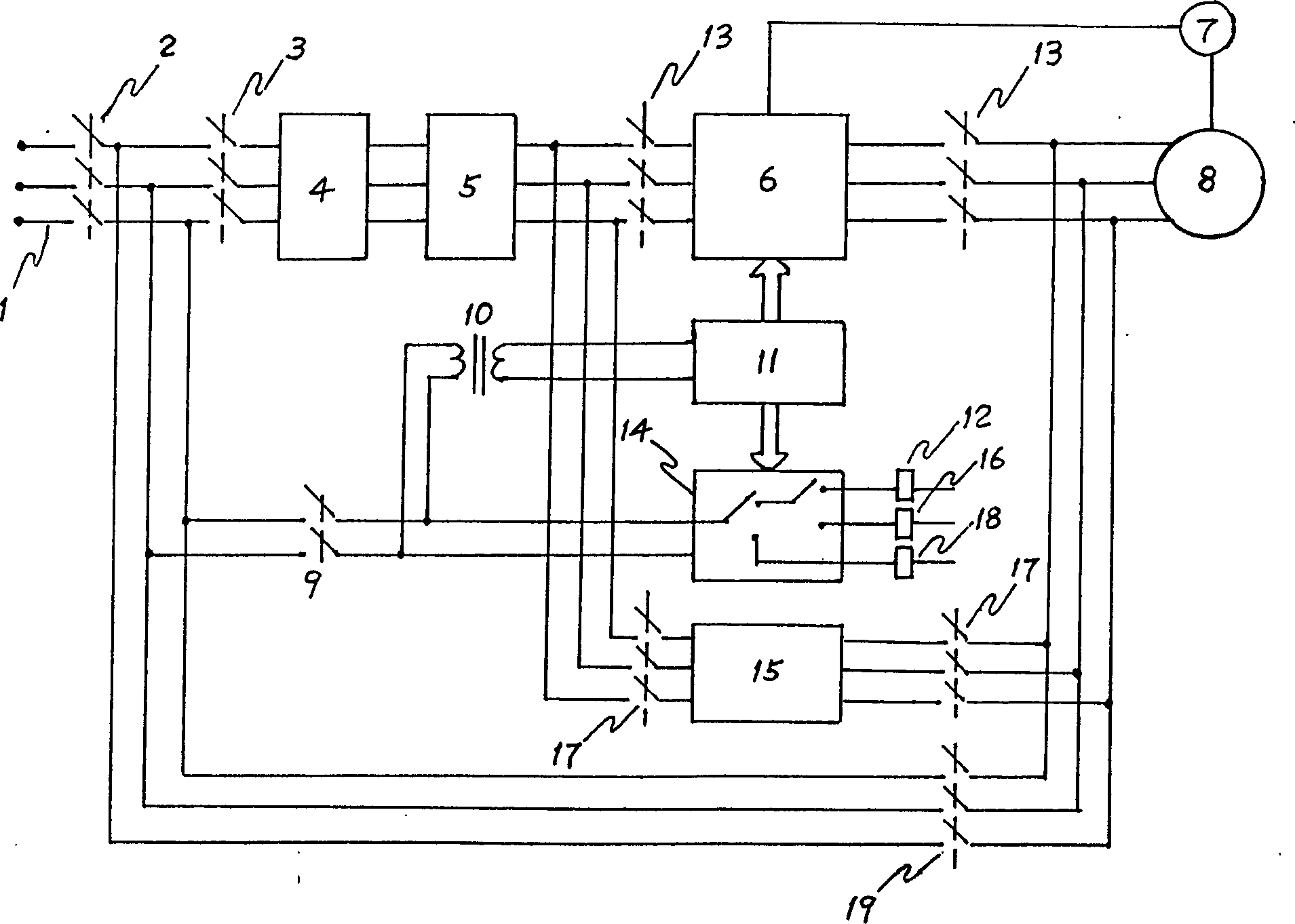

[0015] Embodiment 1. A kind of intelligent driving device of oilfield pumping unit, as figure 1 and image 3 shown. It consists of a three-phase main circuit 1 and its control circuit installed on the drive motor of the pumping unit. A circuit breaker 2, a circuit breaker 2 3, a power filter 4, an AC reactor 5 and an AC servo controller 6 are sequentially connected in series on the main circuit. A position sensor 7 is also connected between the AC servo controller 6 and the drive motor 8 . The position sensor 7 is located on the shaft of the drive motor 8 . The control circuit consists of a transfer switch 9 connected to the two phases between the circuit breaker 1 2 and the circuit breaker 2 3 of the three-phase main circuit 1, a control transformer 10 connected to the transfer switch 9, and a secondary circuit connected to the control transformer 10. The control computer 11 on the winding and the AC servo controller 6 is formed.

[0016] Embodiment 1 is a mode in which ...

Embodiment 2

[0017] Embodiment 2. A kind of intelligent driving device of oilfield pumping unit, refer to Figure 1 ~ Figure 4 . The two ends of the AC servo controller 6 on the main circuit 1 are respectively connected to a normally open contact group 13 of an AC contactor 12, and the transfer switch 9 is also connected to a control computer 11 for switching on the AC contactor. One 12 or the switching device 14 of the coil of the AC contactor two 16, between the AC reactor 5 on the main circuit 1 and the normally open contact group 13 of the AC contactor one 12 and between the driving motor 8 is also connected with a soft The start controller 15 and the two ends of the soft start controller 15 are respectively connected to a normally open contact group 17 of an AC contactor 2 16 .

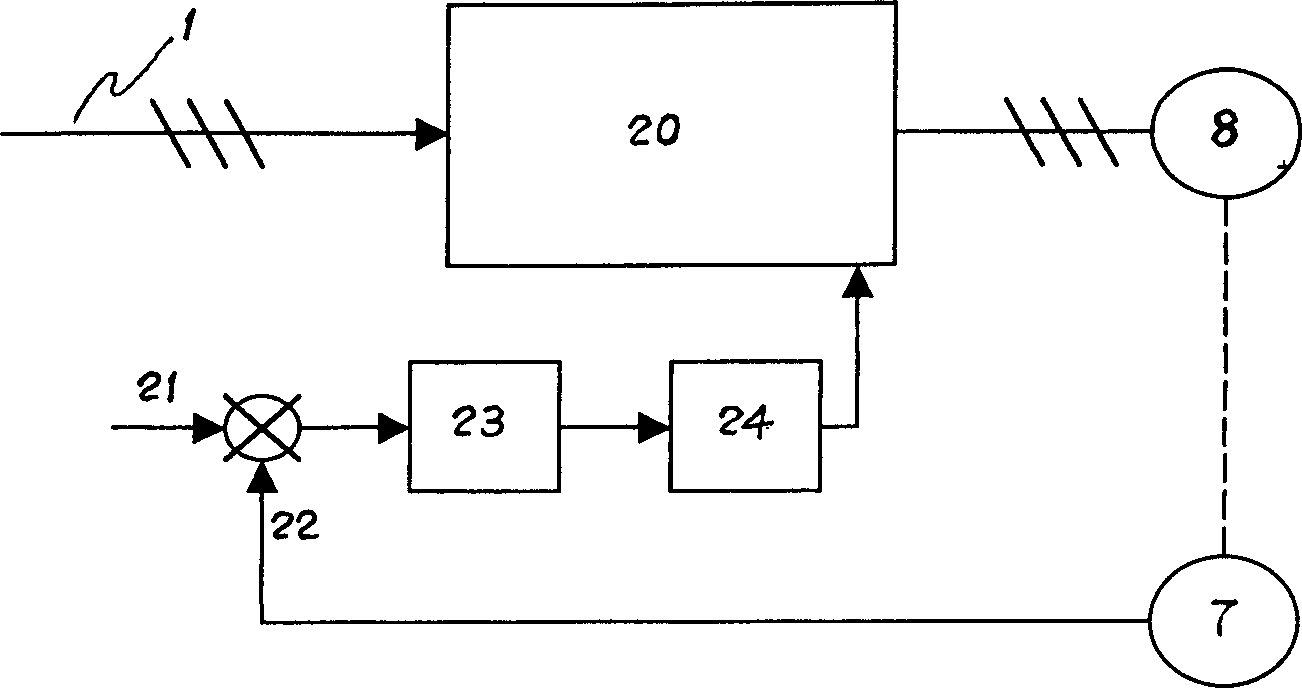

[0018] The soft start controller 15 is connected to the rotational speed regulator 23 controlled by the bidirectional thyristor voltage regulator 20 connected on the main circuit 1 and the position signal 22...

Embodiment 3

[0020] Embodiment 3. A kind of intelligent driving device of oilfield pumping unit, refer to image 3 . Its three-phase main circuit 1 is also connected with a normally open contact group 19 of an AC contactor three 18 between the circuit breaker one 2 and the circuit breaker two 3 and between the drive motor 8, and the said transfer switch 9 is connected A switching device 14 that can be controlled by the control computer 11 is used to switch the coils of AC contactor one 12, AC contactor two 16 or AC contactor three 18. Switching device 14 also has manual switch.

[0021] Embodiment 3 is a mode in which the motor is directly driven by the power frequency power supply of the power grid. That is to say, under special circumstances, if the control computer or the servo system fails, or the state of the oil well itself is abnormal, the system can automatically switch to the power frequency power supply of the power grid, and the main circuit 1 is normally open through the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com