Alkaline storage battery with scroll electrode body

A scroll-shaped electrode body technology, which is applied to the conductive connection between the scroll-shaped electrode body and the metal outer can, and the conductive connection between the scroll-shaped electrode body and the current collector, which can solve the problem of reducing the operating voltage and current Problems such as uneven distribution and non-welding of the current collector for the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

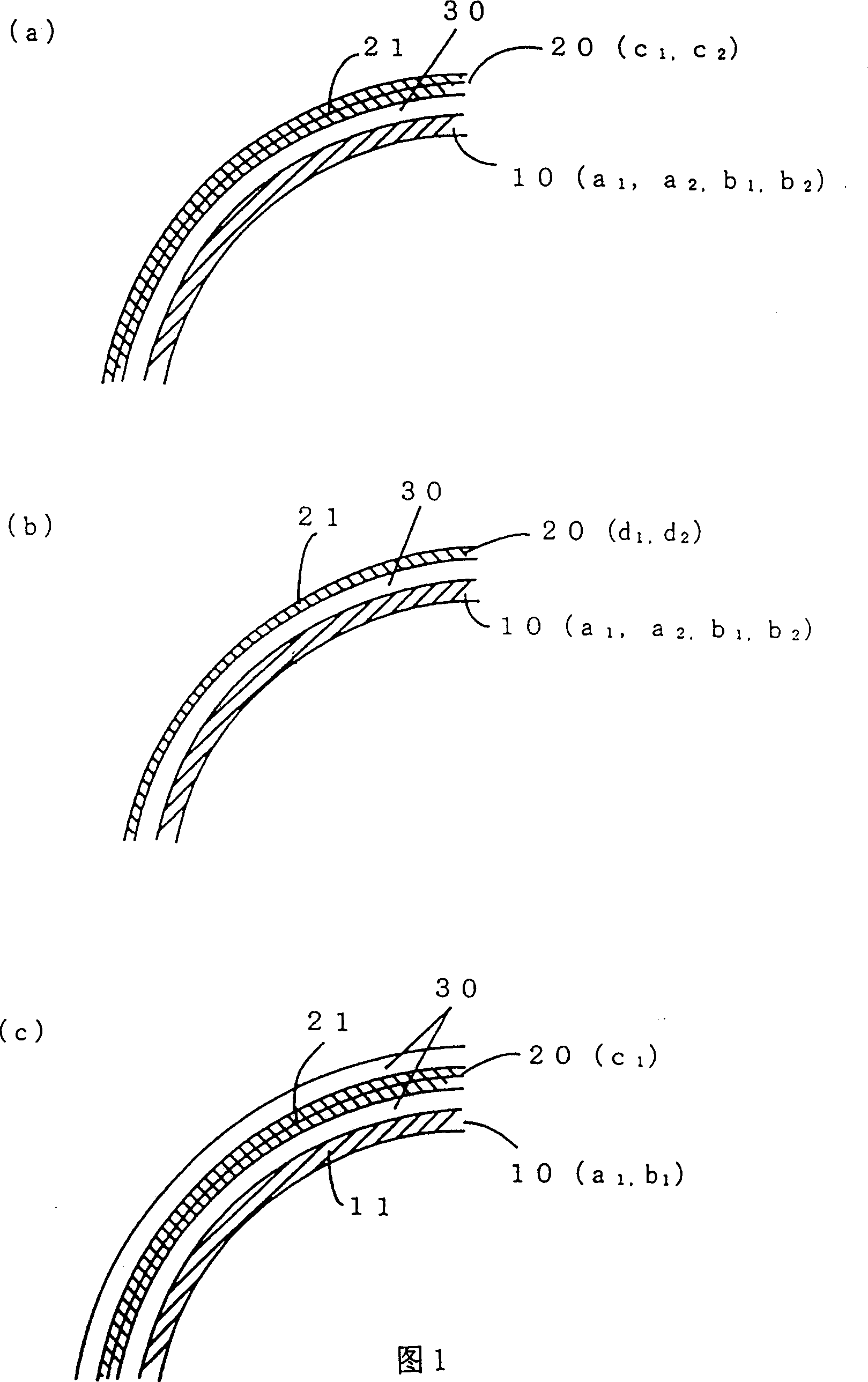

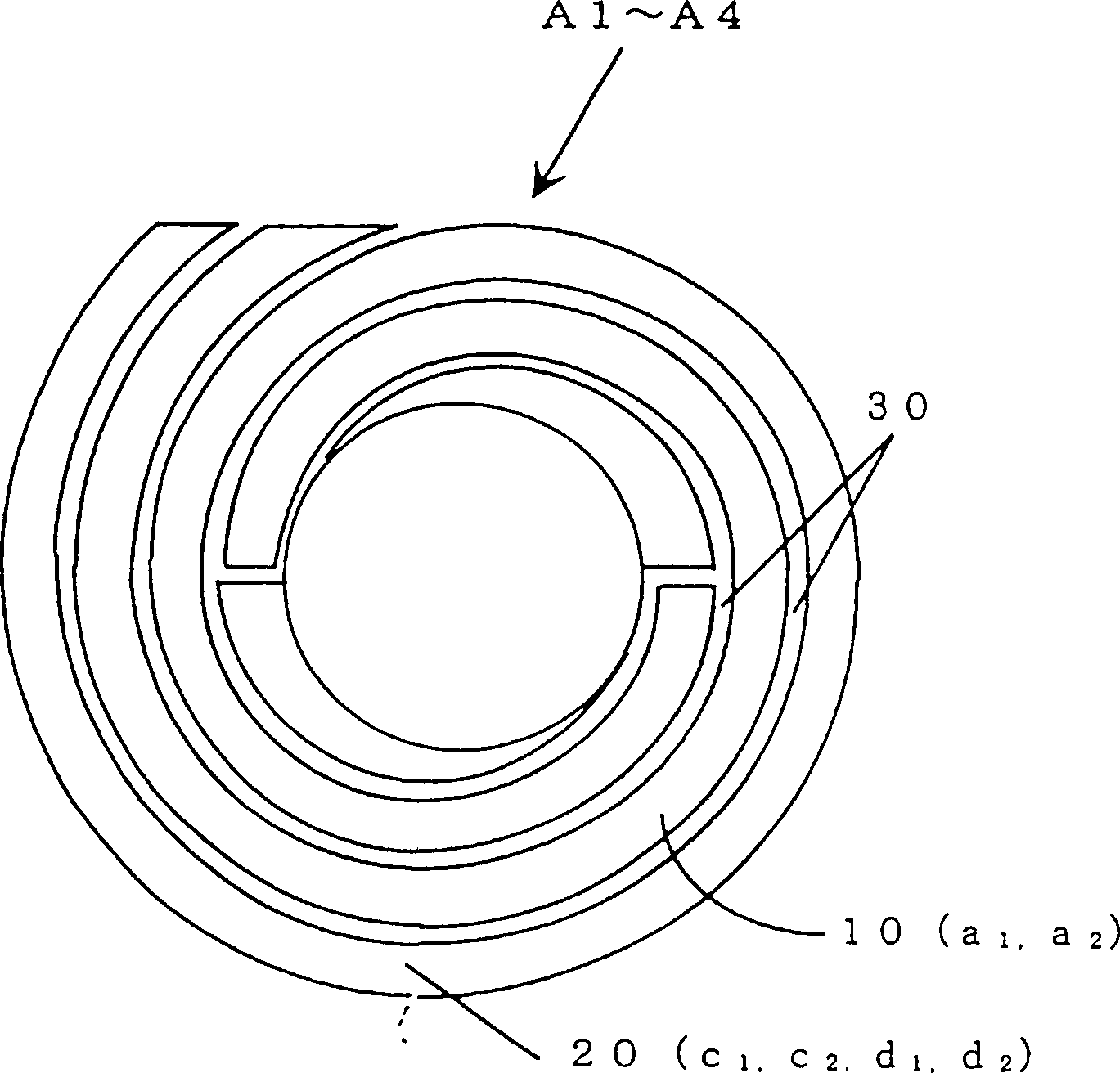

[0033] A separator 30 made of polypropylene non-woven fabric is placed between the sintered nickel positive electrode plate a1 and the hydrogen-absorbing alloy negative electrode plate c1 prepared above, and the upper end of the positive electrode plate a1 is lower than the upper end of the separator 30. protruding, the lower end of the negative plate c1 protrudes more than the lower end of the separator 30 for accumulation, and then uses a winding core not shown in the figure, as shown in Figure 1 (a) and figure 2 As shown, the negative electrode plate c1 is wound in a spiral shape on the outermost periphery to produce a spiral electrode group A1. The diameter of the spiral electrode group wound in a spiral shape in this way was about 22 mm. In addition, a negative electrode active material exists outside the core body of the negative electrode plate c1 on the outermost periphery of the spiral electrode group A1.

[0034] Thereafter, the lower end of the negative electrode p...

Embodiment 2

[0036] A separator 30 made of polypropylene non-woven fabric is placed between the sintered nickel positive electrode plate a1 and the hydrogen-absorbing alloy negative electrode plate d1 prepared above, and the upper end of the positive electrode plate a1 is lower than the upper end of the separator 30. protruding, the lower end of the negative plate d1 protrudes more than the lower end of the separator 30 for accumulation, and then adopts a winding core not shown in the figure, as shown in Figure 1(b) and figure 2 As shown, the negative electrode plate d1 is wound in a spiral shape on the outermost periphery to produce a spiral electrode group A2. The diameter of the spiral electrode group A2 wound in a spiral shape in this way is about 22 mm. In addition, no negative electrode active material exists outside the plate core of the negative electrode plate d1 on the outermost periphery of the spiral electrode group A2. Afterwards, the lower end of the negative electrode plate...

Embodiment 3

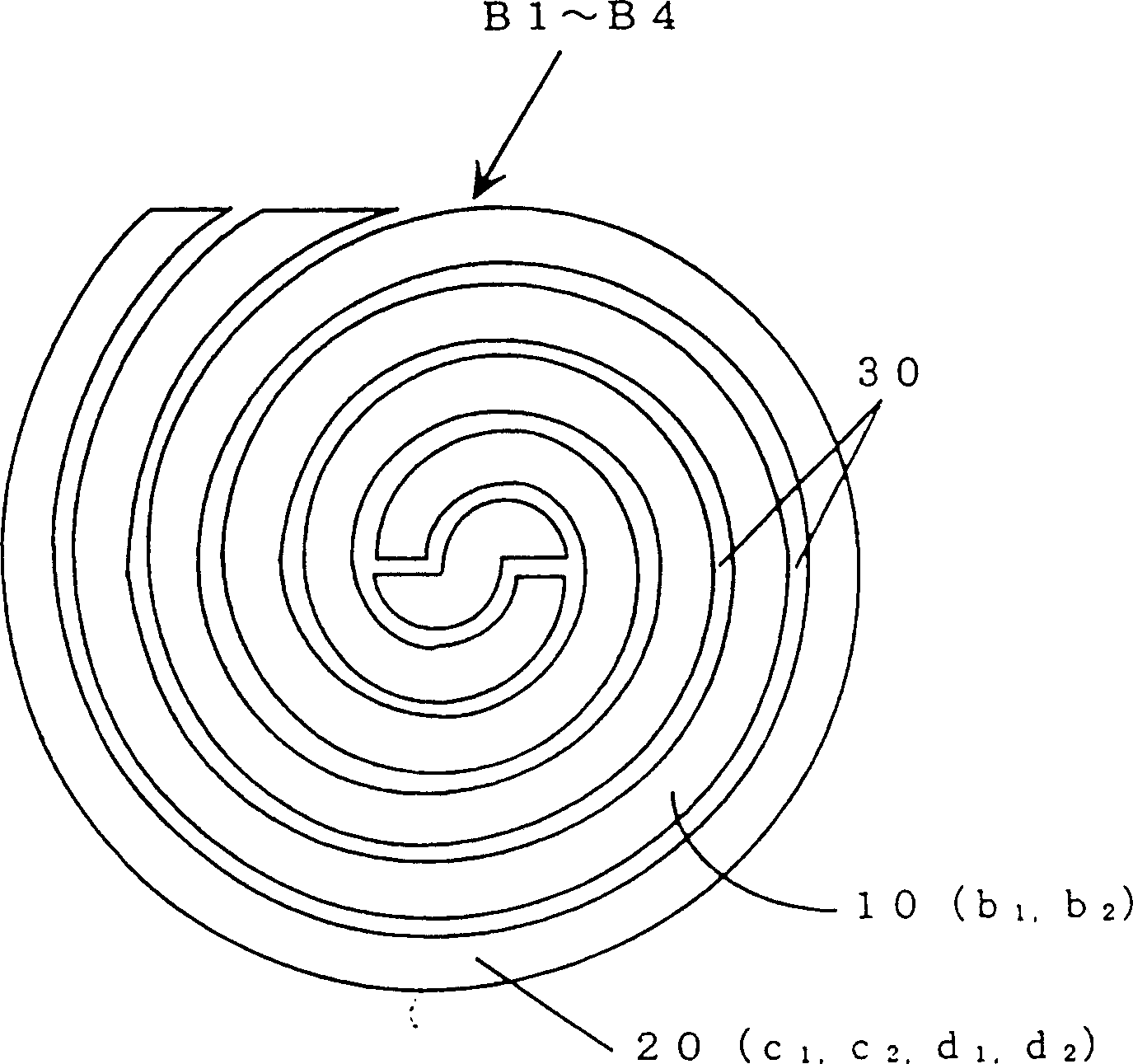

[0038] A separator 30 made of polypropylene non-woven fabric is placed between the sintered nickel positive plate a2 and the hydrogen-absorbing alloy negative plate c2 produced above, and the upper end of the positive plate a2 is lower than the upper end of the separator 30. protruding, the lower end of the negative plate c2 is more protruding than the lower end of the separator 30 for accumulation, and then adopts a winding core not shown in the figure, as shown in Figure 1 (a) and image 3 As shown, the negative electrode plate c2 is wound in a spiral shape on the outermost periphery to produce a spiral electrode group A3. The diameter of the spiral electrode group A3 wound in a spiral shape in this way is about 22 mm. In addition, a negative electrode active material exists outside the core body of the negative electrode plate c2 on the outermost periphery of the spiral electrode group A3. Afterwards, the lower end of the negative electrode plate c2 of the spiral electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com