Hydraulic hammer with micro motion of lower hammer

A technology of hydraulic hammer and hammer head, applied in the field of die forging hydraulic hammer, can solve the problems of poor striking accuracy, inconvenient connection, slow striking speed, etc., and achieve the effect of fast striking speed, convenient connection and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

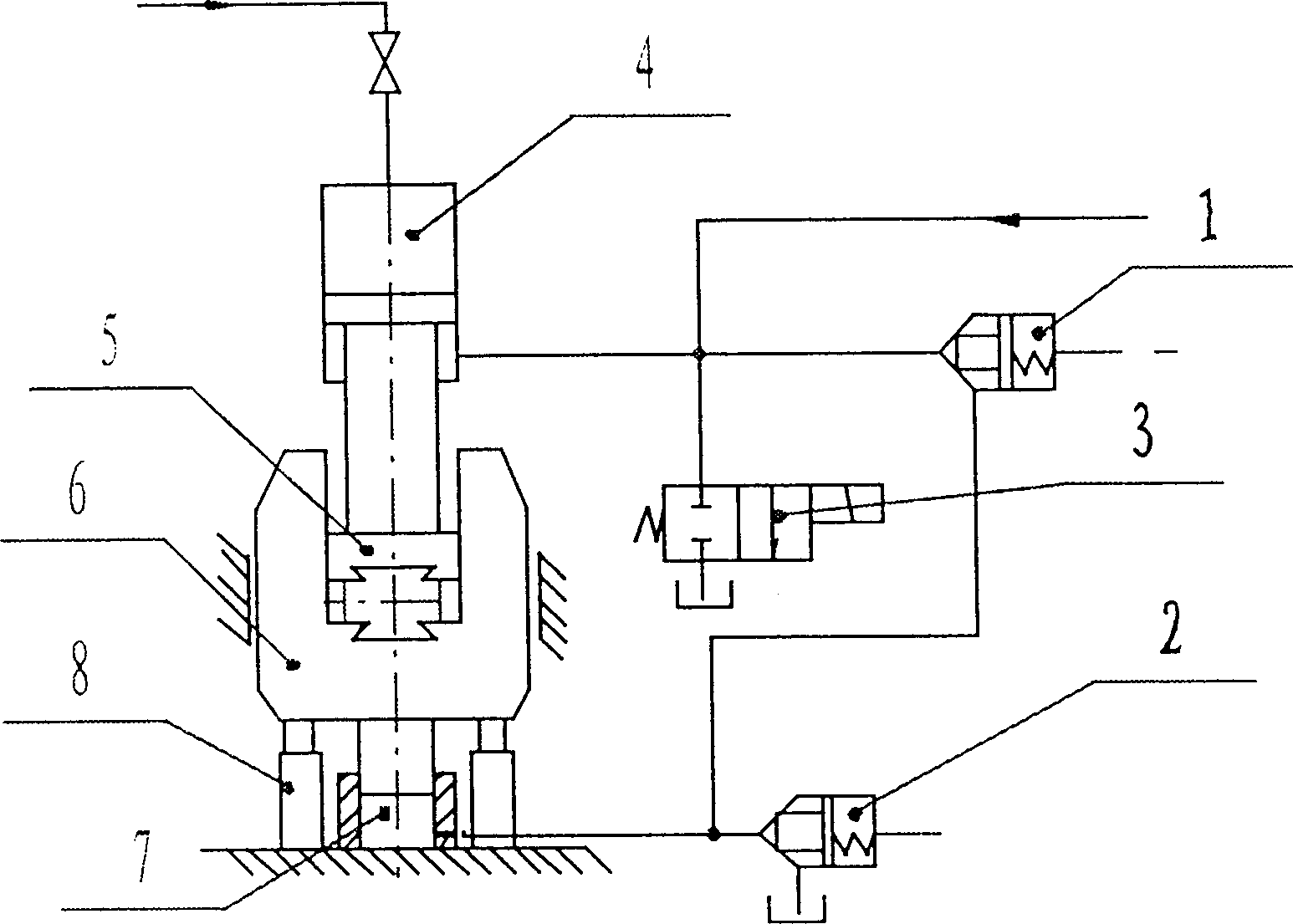

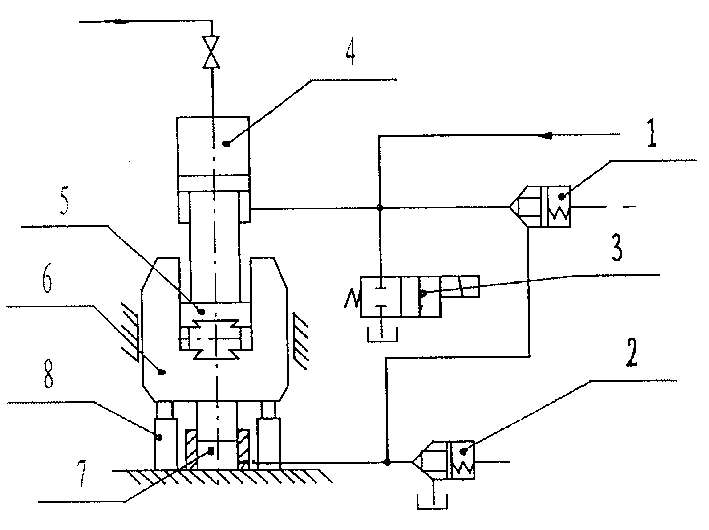

[0014] As shown in the drawings, the lower hammer head micro-motion hydraulic hammer in this embodiment includes an energy storage cylinder 4, an upper hammer head 5 and a U-shaped lower hammer head 6 located at the lower end of the piston rod of the energy storage cylinder 4 , the upper hammer head 5 is loaded into the U-shaped lower hammer head 6, wherein: it also includes an air cushion 8, a communication cylinder 7, and is composed of two two-way cartridge valves 1, 2, and a two-position two-way electromagnetic reversing valve 3 The driving device; the air cushion 8 is located on both sides of the bottom of the U-shaped lower hammer head 6, the communication cylinder 7 is located in the middle of the bottom of the U-shaped lower hammer head 6, and the plunger of the communication cylinder 7 is connected to the bottom surface of the U-shaped lower hammer head 6 , the oil inlet of the first two-way cartridge valve 1 is connected with the oil port of the lower cavity of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com