Process for modifying superfine glass fibre diaphragm of lead-acid accumulator

A battery and cover assembly technology, which is applied to battery components, dry batteries, electrical components, etc., can solve problems such as structural instability, reduced battery capacity, and effective height reduction, so as to achieve structural stability, ensure safety, and realize The effect of increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

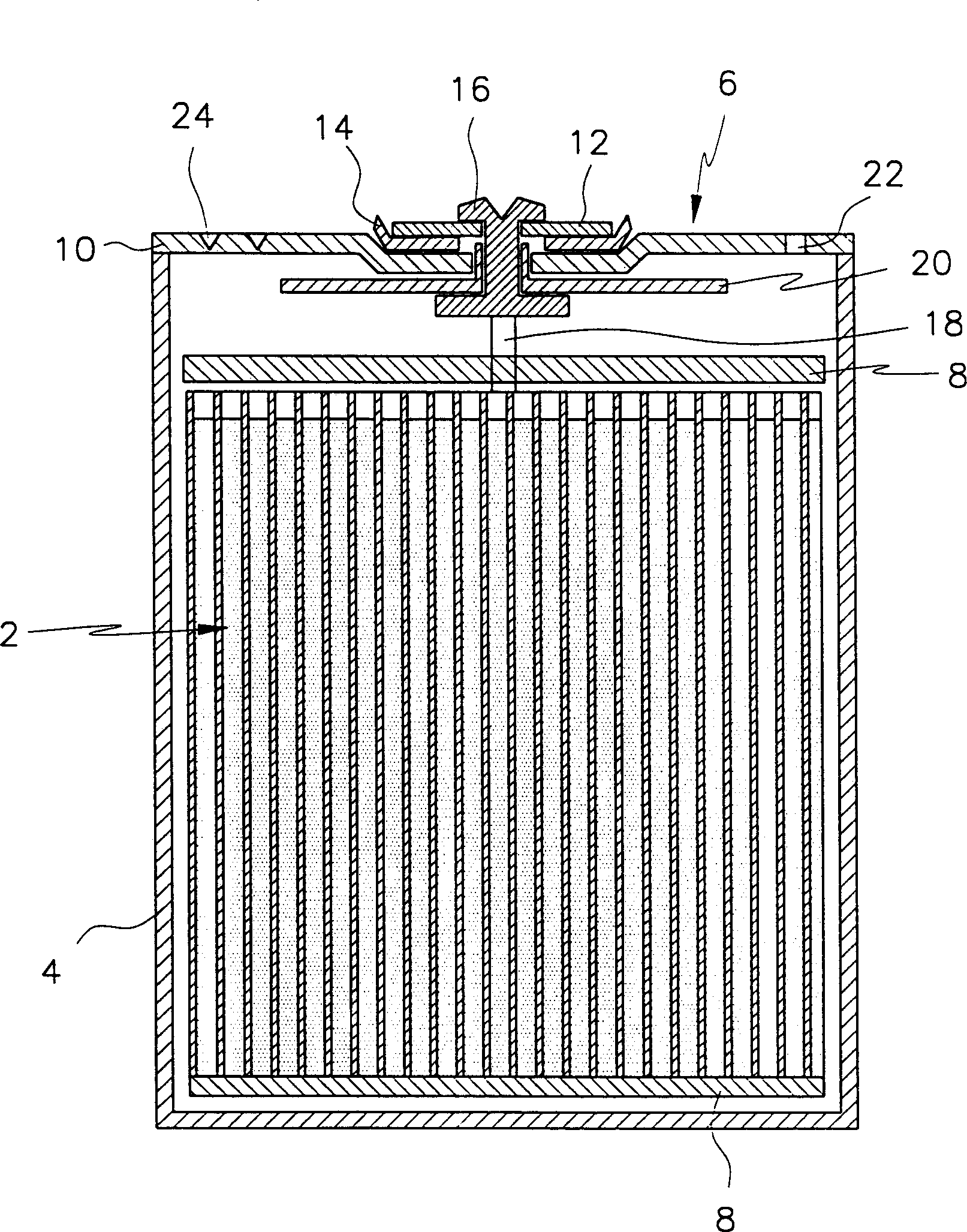

[0044] The preferred embodiment of the present invention will be described in detail below according to the accompanying drawings. In the description of the present invention, the same symbols are used for the same components as those in the drawings cited in the prior art for convenience of description.

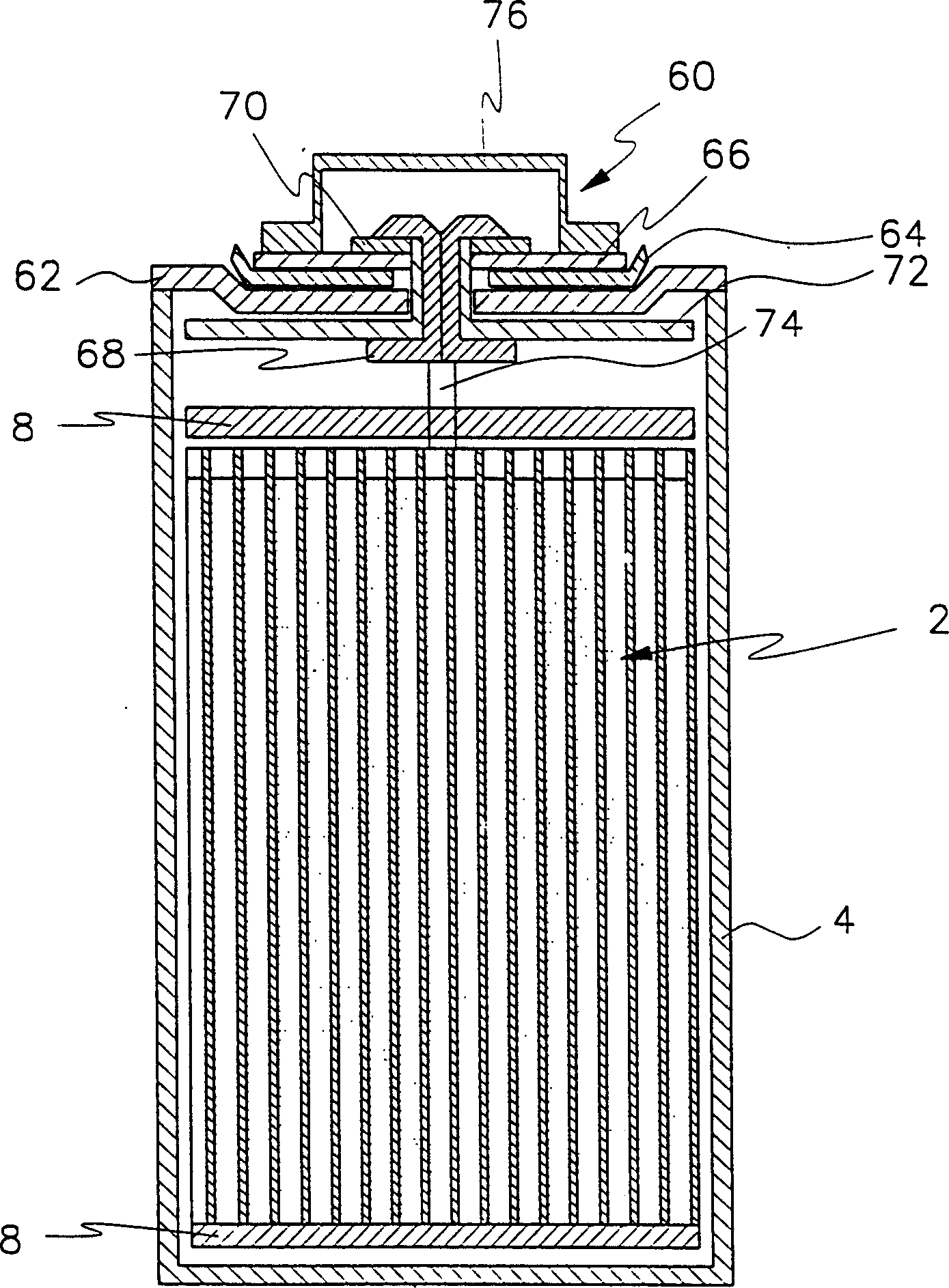

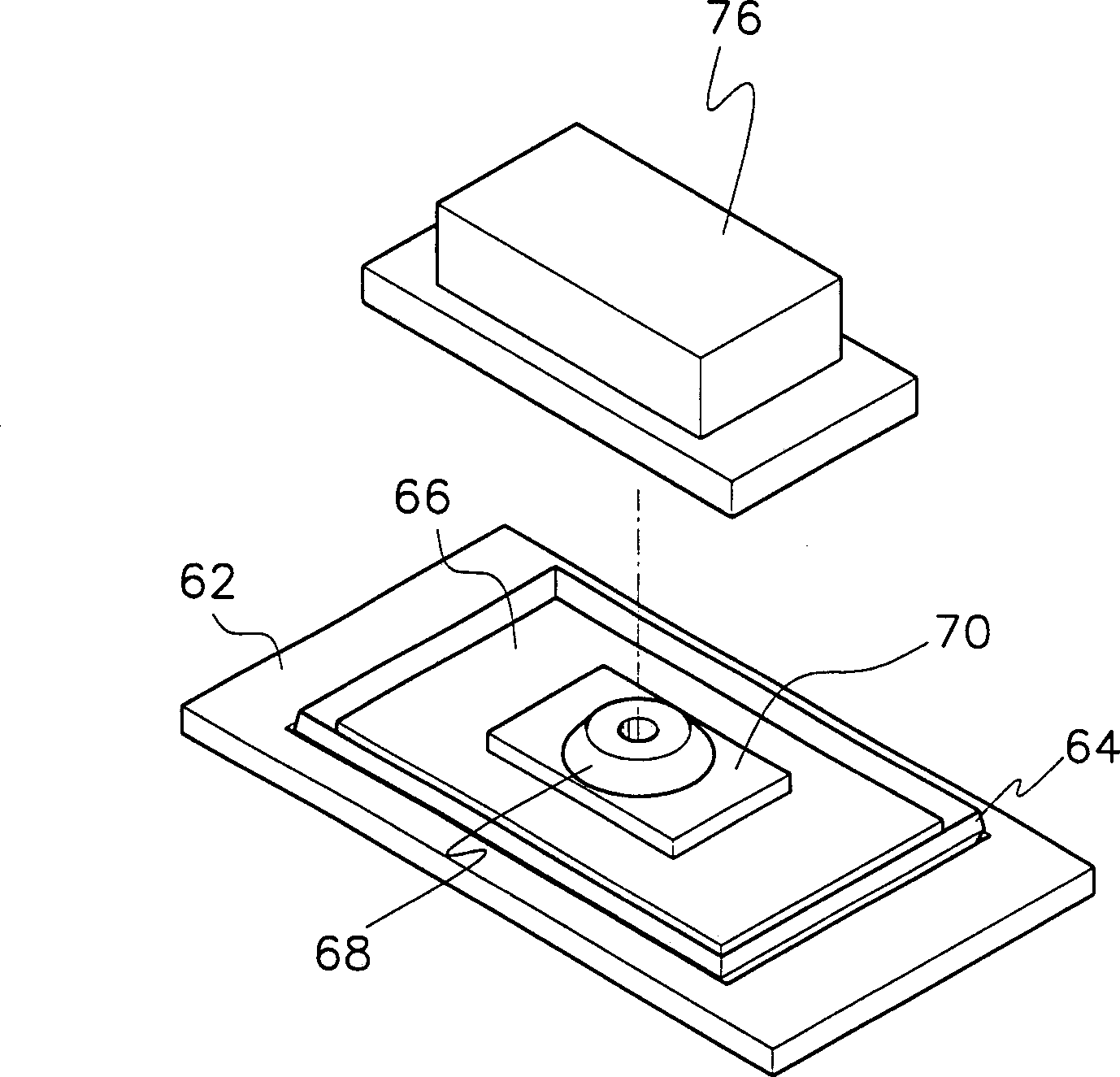

[0045] Such as figure 1 and figure 2 Shown, the square storage battery of the present invention, its structure is: the electrode roll core 2 that is wound together by anode and separator and negative electrode is put into as the protective box that is connected with above-mentioned negative electrode and is in the casing 4, in this casing 4 is provided with a cover assembly 60 for sealing.

[0046] In order to prevent the conductive contact between the shell 4 and the cover assembly, the electrode winding core 2 is equipped with insulating plates 8 on its upper and lower sides respectively, and then put into the inside of the shell 4 . Here, the constituent parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com