A polyurethaneurea elastic fiber, and a process of preparing the same

A polyurethane urea and elastic fiber technology, applied in the direction of single-component polyurethane artificial filament, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problem that the properties and colors of polyurethane elastic fibers are easily changed by sunlight and cannot prevent the properties of elastomers No description of light resistance, exhaust gas resistance, chlorine resistance, anti-oxidation and total weather resistance, etc., to achieve the effect of not deteriorating the original performance, improving light resistance and processability, excellent heat resistance and UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A mixture of 4,4'-diphenylmethane diisocyanate and polytetramethylene ether glycol with a molar ratio of 2.0 was reacted at 90° C. for 90 minutes to prepare isocyanate-terminated polyurethane urea (prepolymer).

[0049] After cooling the prepolymer to 40°C, N,N'-dimethylacetamide was added to prepare a 45% solution containing the prepolymer. Cool the prepolymer solution to 5°C, then, for the preparation of the polyurethaneurea solution, slowly add a solution of N,N'-dimethylacetamide containing 96% equivalents of ethylenediamine and 6% equivalents of diethylamine under vigorous stirring , to grow and / or terminate its chain.

[0050] In the obtained polyurethane urea solution, add 1.2% (weight) of 1,3,5-tri(4-tert-butyl-3-hydroxyl-2,6-xylene)-1 which accounts for 1.2% (weight) of the solids of the polyurethane urea solution , 3,5-triazine-2,4,6-(1H,3H,5H)trione, 1.0% by weight of 1,1,1',1'-tetramethyl-4,4'-( Methylene-two-p-phenylene) diamino acid exhaust gas stabilize...

Embodiment 2

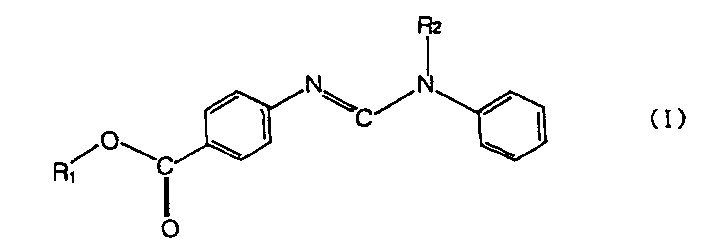

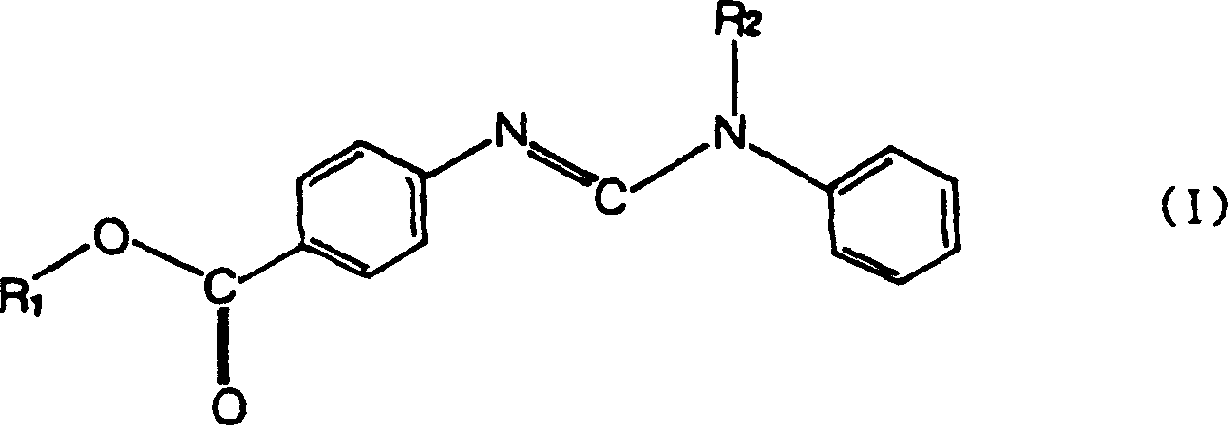

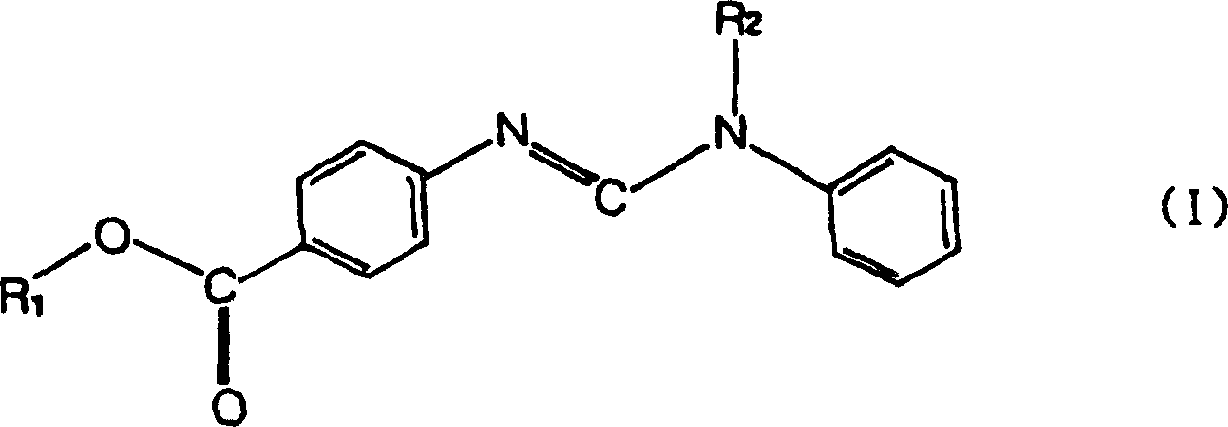

[0052] Use the method identical with embodiment 1, make polyurethane urea elastic fiber, difference is to use the additive N of 1.5% (weight). 2 -(4-carboethoxyphenyl)-N 1 -Methyl-N 1 - phenylformamidine UV absorber. Then, the light resistance, oxidation resistance (heat resistance), chlorine resistance and exhaust gas resistance of the fibers were evaluated, and the results are shown in Table 1 below.

Embodiment 3

[0054] Use the method identical with embodiment 1, make polyurethane urea elastic fiber, difference is to use the additive N of 1.0% (weight). 2 -(4-carboethoxyphenyl)-N 1 -Methyl-N 1 - phenylformamidine UV absorber. Then, the light resistance, oxidation resistance (heat resistance), chlorine resistance and exhaust gas resistance of the fibers were evaluated, and the results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com