Gas supplying device

A gas supply and gas supply device technology, applied in the direction of liquid fuel supply/distribution, application, combustion methods, etc., can solve the problems of high price, insignificant availability, and danger, and achieve low price, high use value, The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

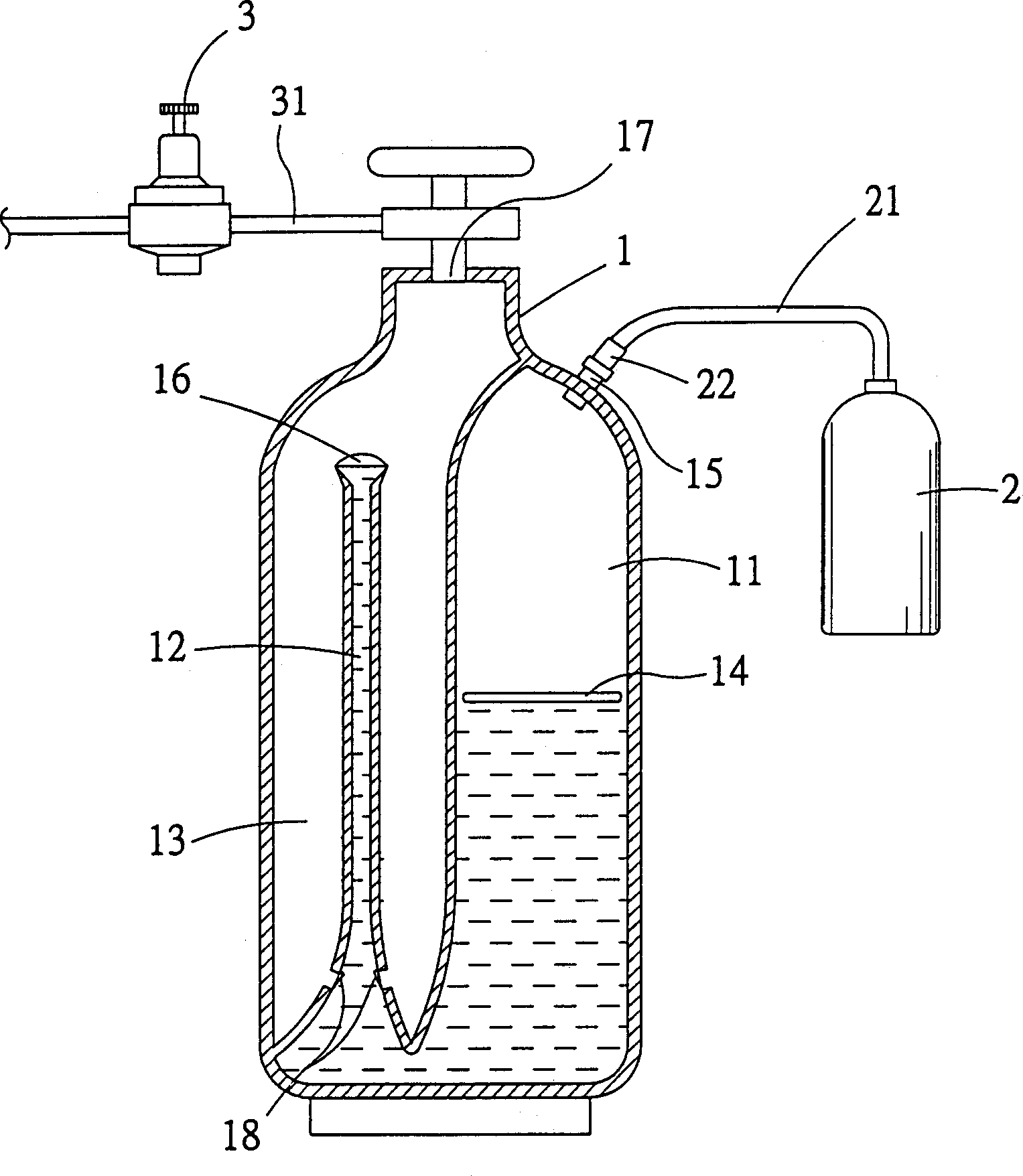

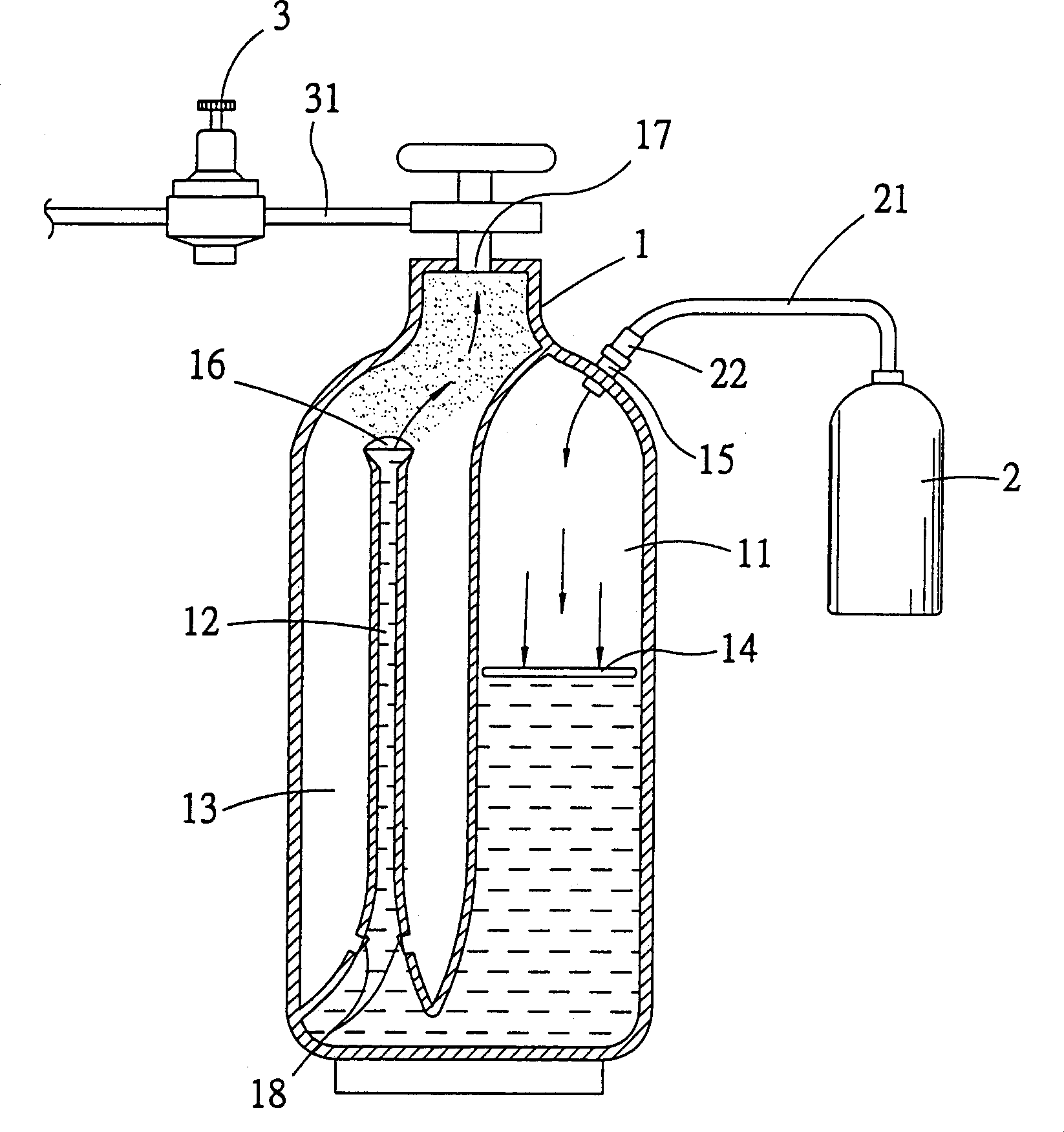

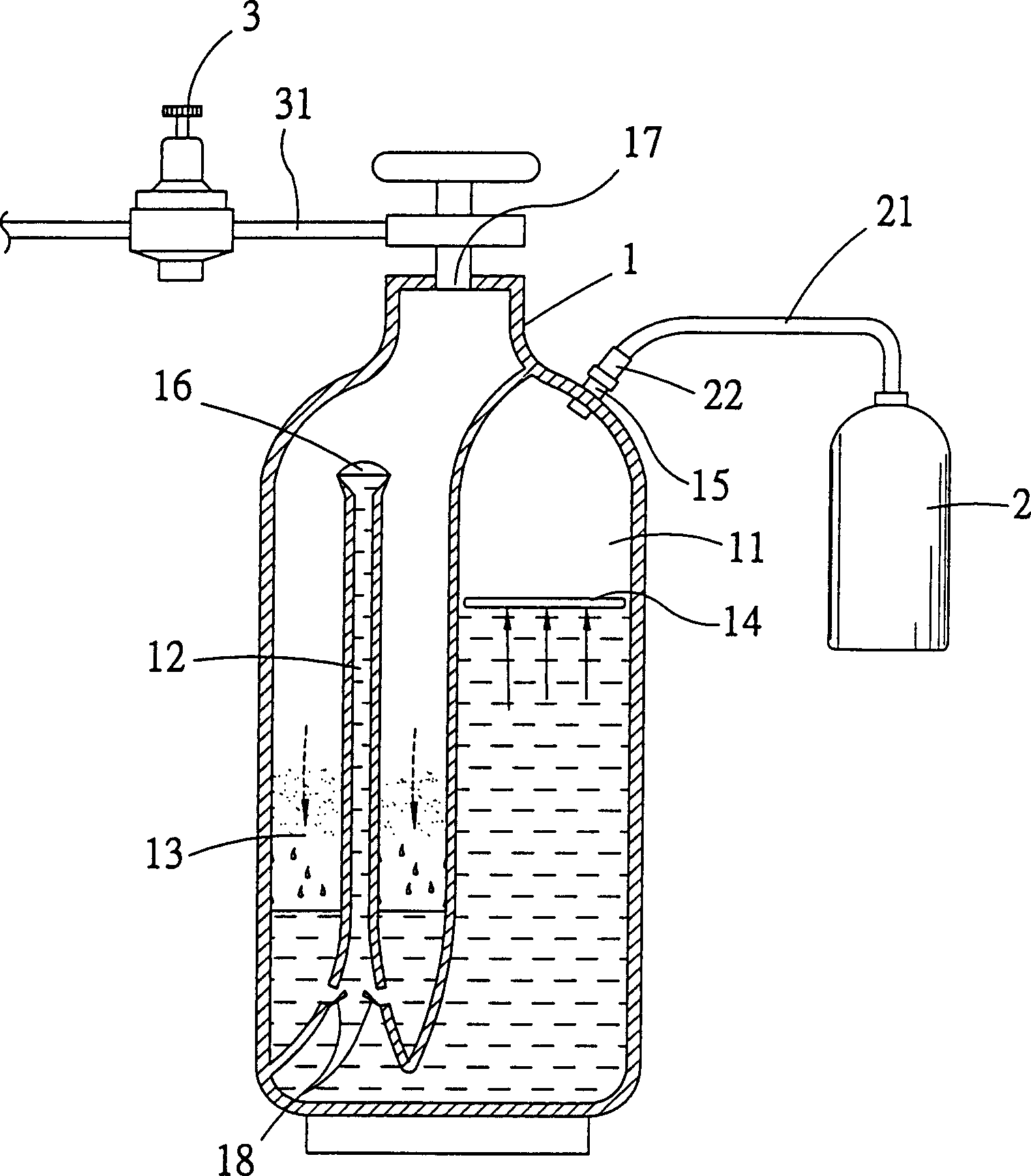

[0021] see figure 1 , is a schematic diagram of the structure of the present invention. As shown in the figure: a kind of combustible gas supply device of the present invention is to provide the liquid fuel (such as green seed oil) that can produce combustible gas through stirring effect, and can output combustible gas, which includes:

[0022] A container 1, its inner area is divided into a first chamber 11, a second chamber 12 and a third chamber 13, the bottoms of the first chamber 11 and the second chamber 12 communicate with each other, and the first chamber 11 The sectional area is much larger than the sectional area of the second chamber 12; a movable floating plate 14 is preset inside the first chamber 11, and an air inlet 15 connected to the outside of the container 1 is preset on the top for air intake And replenishing liquid fuel: the top of the second chamber 12 is an atomizing nozzle 16: the third chamber 13 is located outside the second chamber 12, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com