Stereo image picture and its production process

A technology for stereoscopic images and photos, applied in the field of printing decoration, can solve the problems of inability to reflect depth-of-field images, poor multi-color printing effect, unclear stereoscopic levels, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

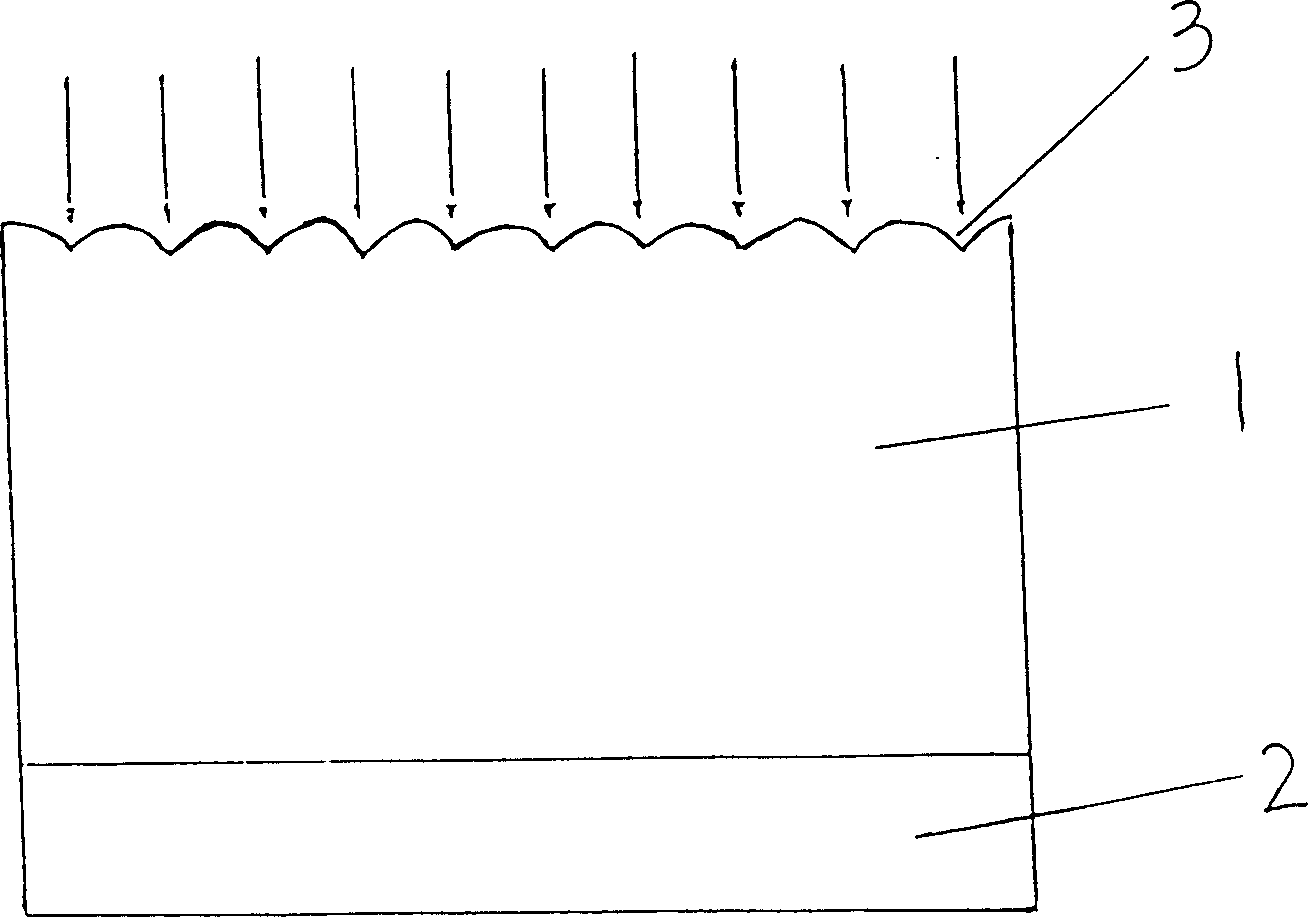

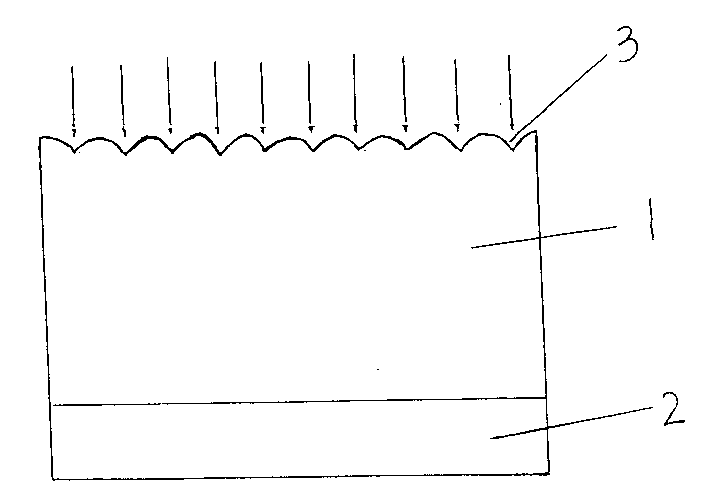

[0011] The transparent film material is selected as PET resin. First, the PET resin is processed into an extruded film with grating stripes and grooves, and the pattern layer printed by multiple cross-screen plate-making methods is directly printed on the back of the extruded film at room temperature, and the grating stripes are aligned in parallel with the pattern layer. . After the incident light is reflected by the grating stripes, a multi-level and multi-color three-dimensional image can be obtained.

example 2

[0013] The transparent film material is selected as PVC resin. First, the PVC resin is processed into an extruded film with grating stripes and grooves, and the grating stripes are aligned parallel to the pattern layer printed by the principle of multiple cross-screens, and are attached to the surface of the pattern layer with an adhesive.

example 3

[0015] The transparent film material is selected as PVC resin. Firstly, the PVC resin is processed into a film, and the pattern layer of multiple cross-screen plate making is directly printed on the back of the film, and then the surface of the film is extruded to form an image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com