Stee-made tyre cord of radial tyre

A technology for radial tires and cords, applied in the field of steel cords for radial tires, can solve the problems of reducing tire service life, accelerating cord corrosion, etc., and achieves the effect of less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

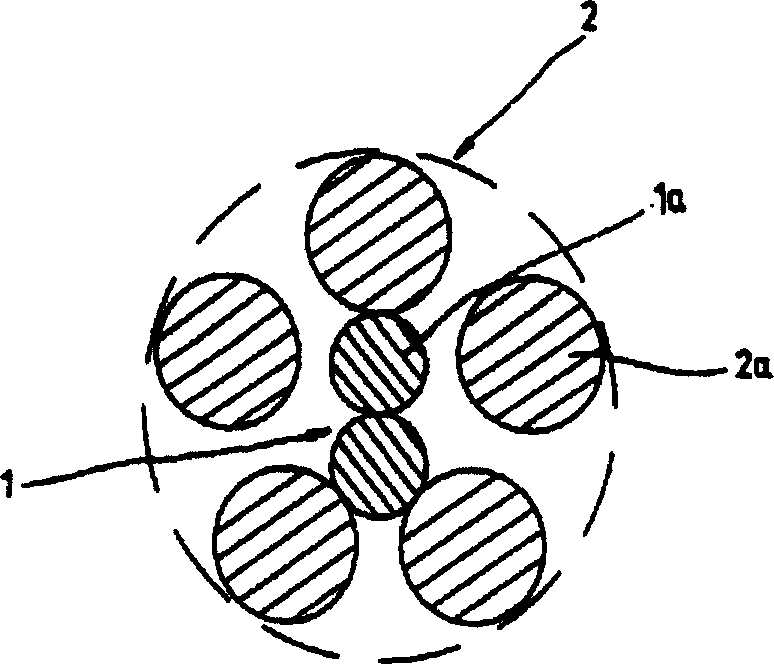

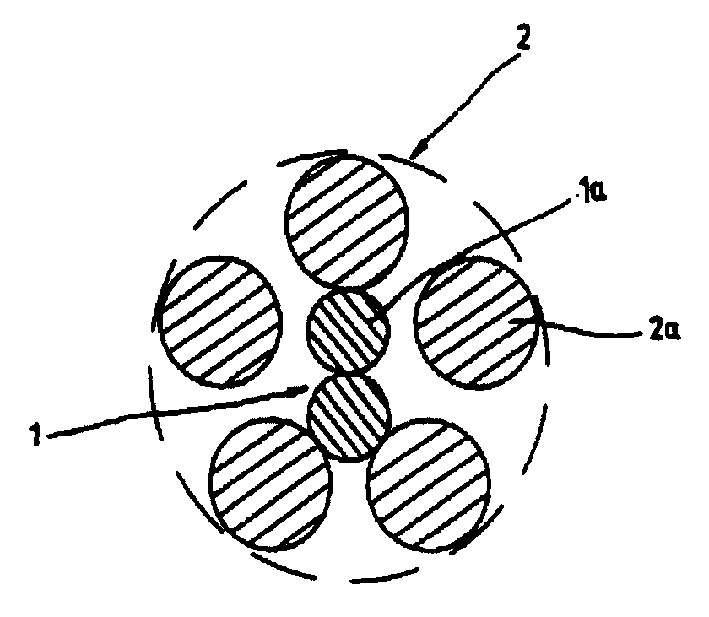

[0022] Referring to Figure 1, there is shown a steel cord having a construction according to the present invention.

[0023] As shown in FIG. 1, the steel cord includes a core layer 1 composed of two twisted filaments 1a, and a core layer 1 arranged around the core layer 1 and composed of five twisted filaments 2a. Strand layer 2. According to the invention, the filaments 1a and 2a are made of carbon steel in which the carbon content is 0.70% to 0.96% by weight. In order to obtain an improved adhesion to rubber, the filaments 1a and 2a are plated with brass. The filaments 1a in the core layer 1 and the filaments 2a in the strand layer 2 have the same twist pitch and the same twist direction. Preferably, the twisting pitch has a length ranging from 10 mm to 22 mm. It is also preferable that the filaments 1a and 2a in the core layer 1 and the strand layer 2 have a thickness of 260kgf / mm before twisting the filaments to form a steel cord. 2 ~385kgf / mm 2 of tensile strength. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com