Double speed motor with forced circulation

A technology of motor and fluid pressure, applied in the direction of servo motor, remote control motor, servo motor assembly, etc., can solve the problem of unexpected rotation of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

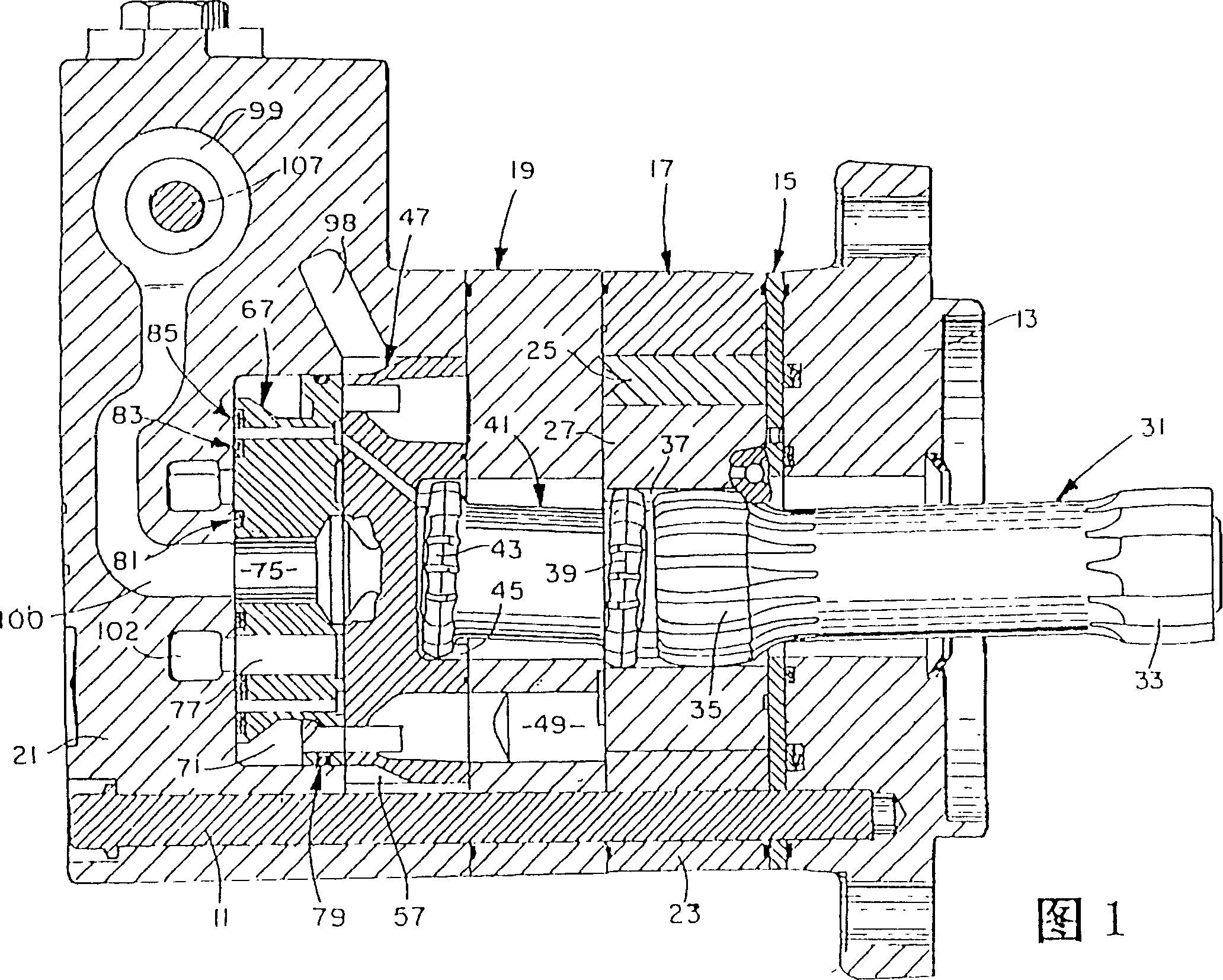

[0026] Referring now to the accompanying drawings, the accompanying drawings are not intended to limit the present invention, Figure 1 is an axial sectional view of a rotary motor applicable to the present invention, which is described and illustrated in more detail in U.S. Patent No. 3,572,983, This patent is incorporated by reference in this specification. More specifically, the swing motor shown in FIG. 1 is a rotating disk, two-speed type, described and illustrated in more detail in the aforementioned US Patent No. 4,480,971. When applied to a device of the kind shown here, the term "motor" shall obviously also include such a device used as a pump.

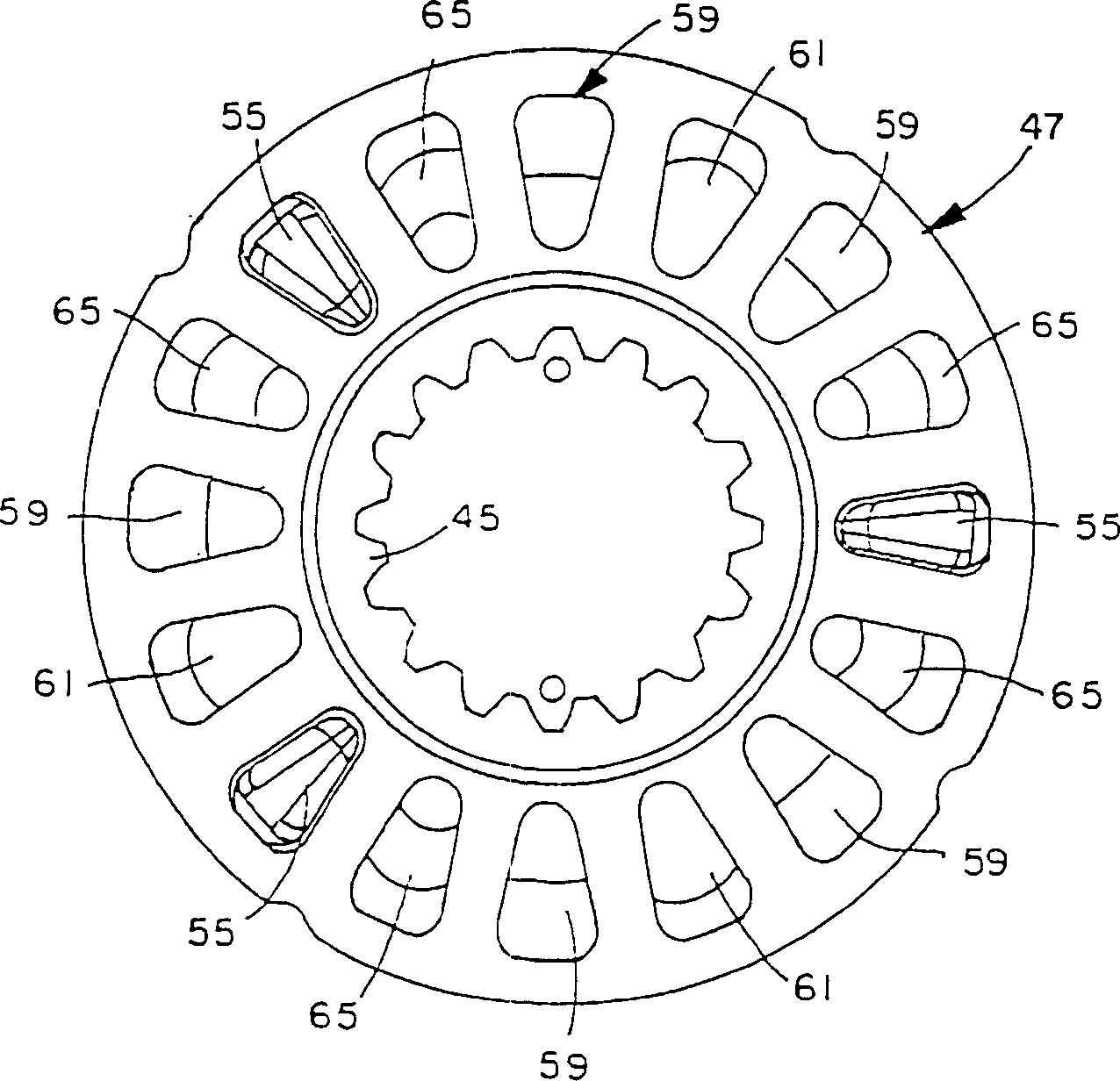

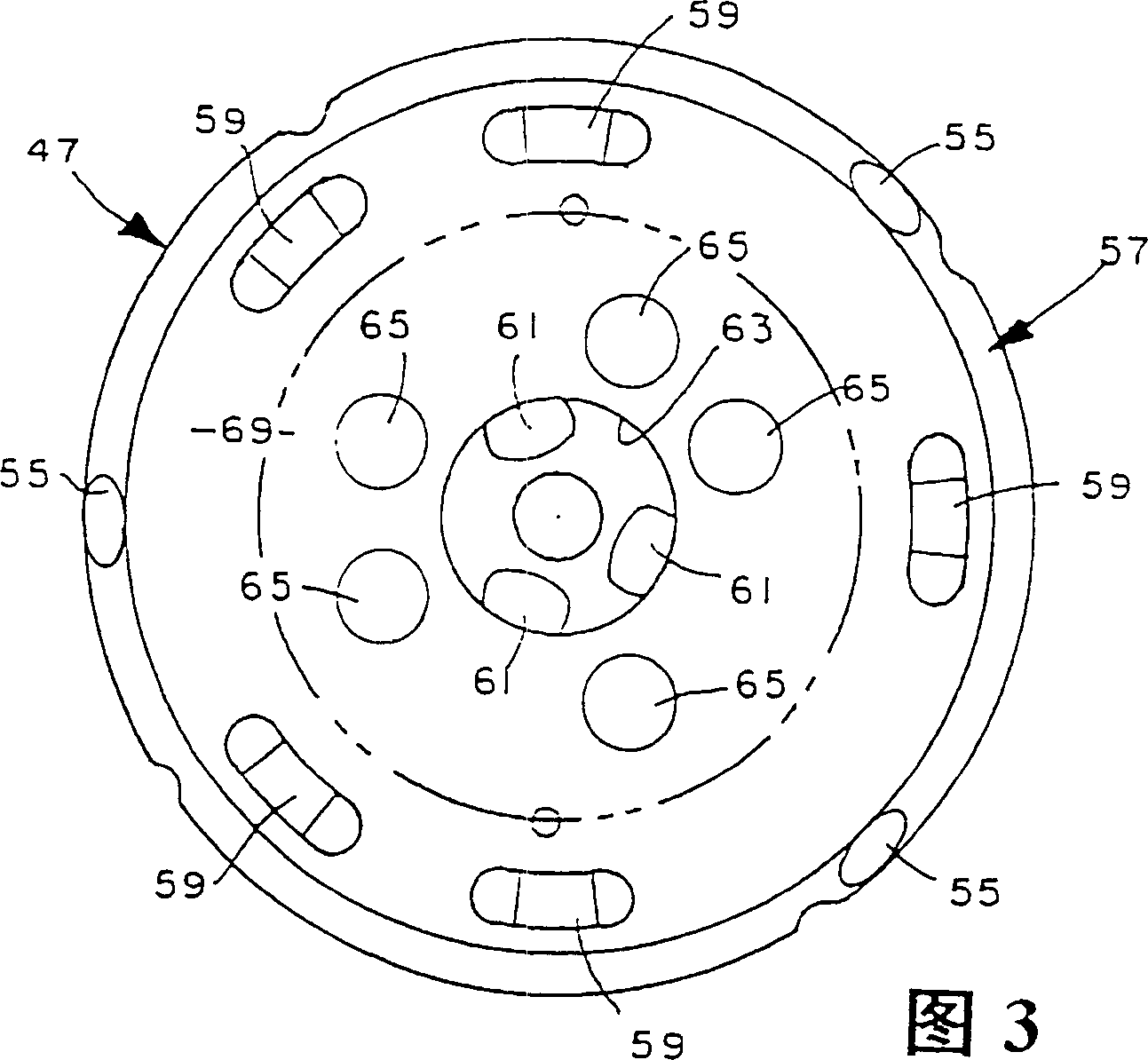

[0027] The rotary motor shown in Fig. 1 comprises a plurality of parts fastened together eg by a plurality of bolts 11 (only one of which is shown in Fig. 1). The motor includes a front flange member 13 , a wear plate 15 , a gerotor displacement mechanism 17 , an orifice or stationary valve means 19 and a valve housing portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com