Liquid delivery device with blocking clutch

A transmission device, clutch technology, applied in the direction of fluid transmission, transmission, belt/chain/gear, etc., can solve the problems of difficulty in ensuring the durability of sealing elements, increase in the number of parts, increase in cost, etc., to achieve enhanced connection responsiveness, The effect of cost reduction and durability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

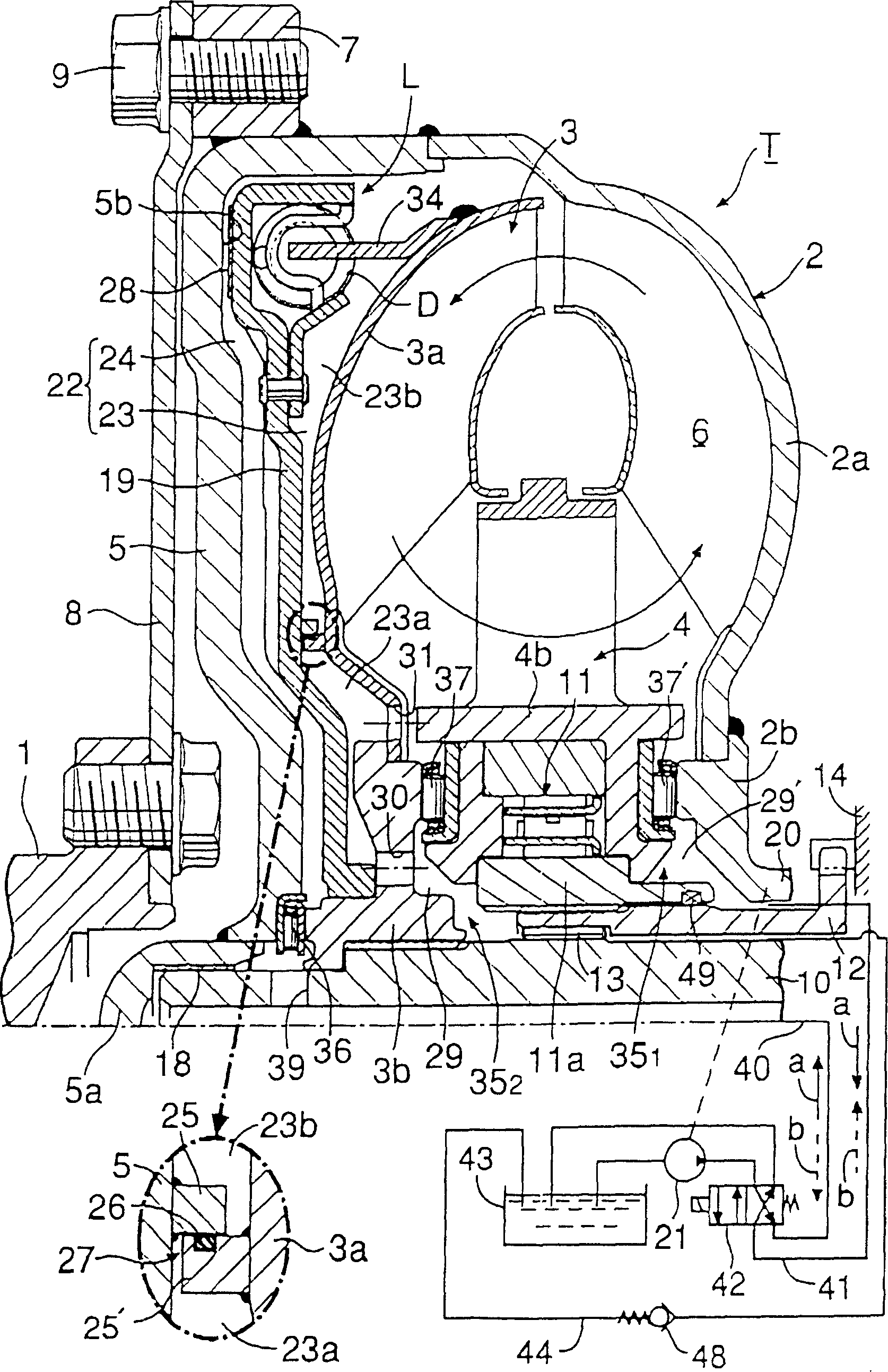

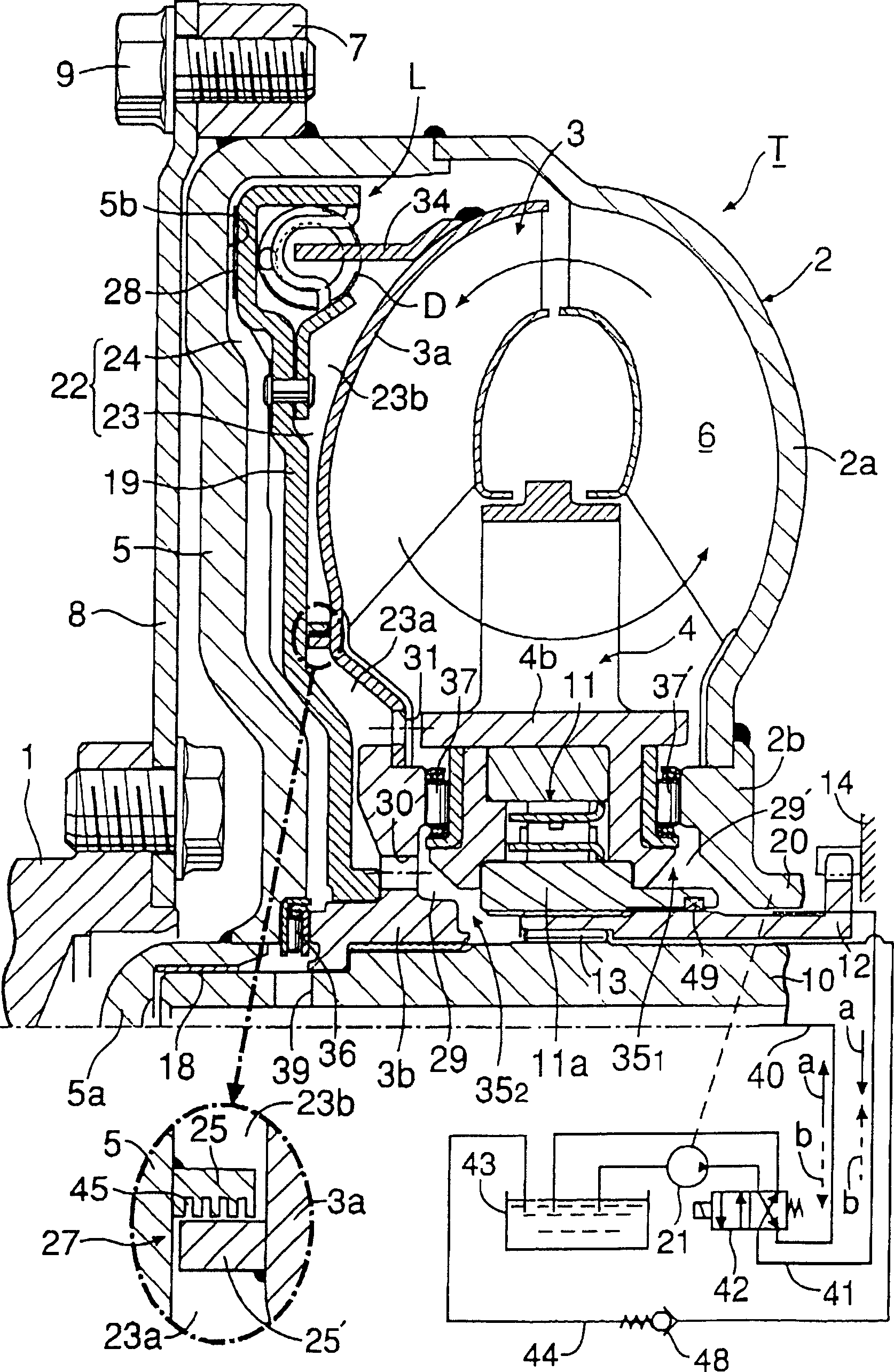

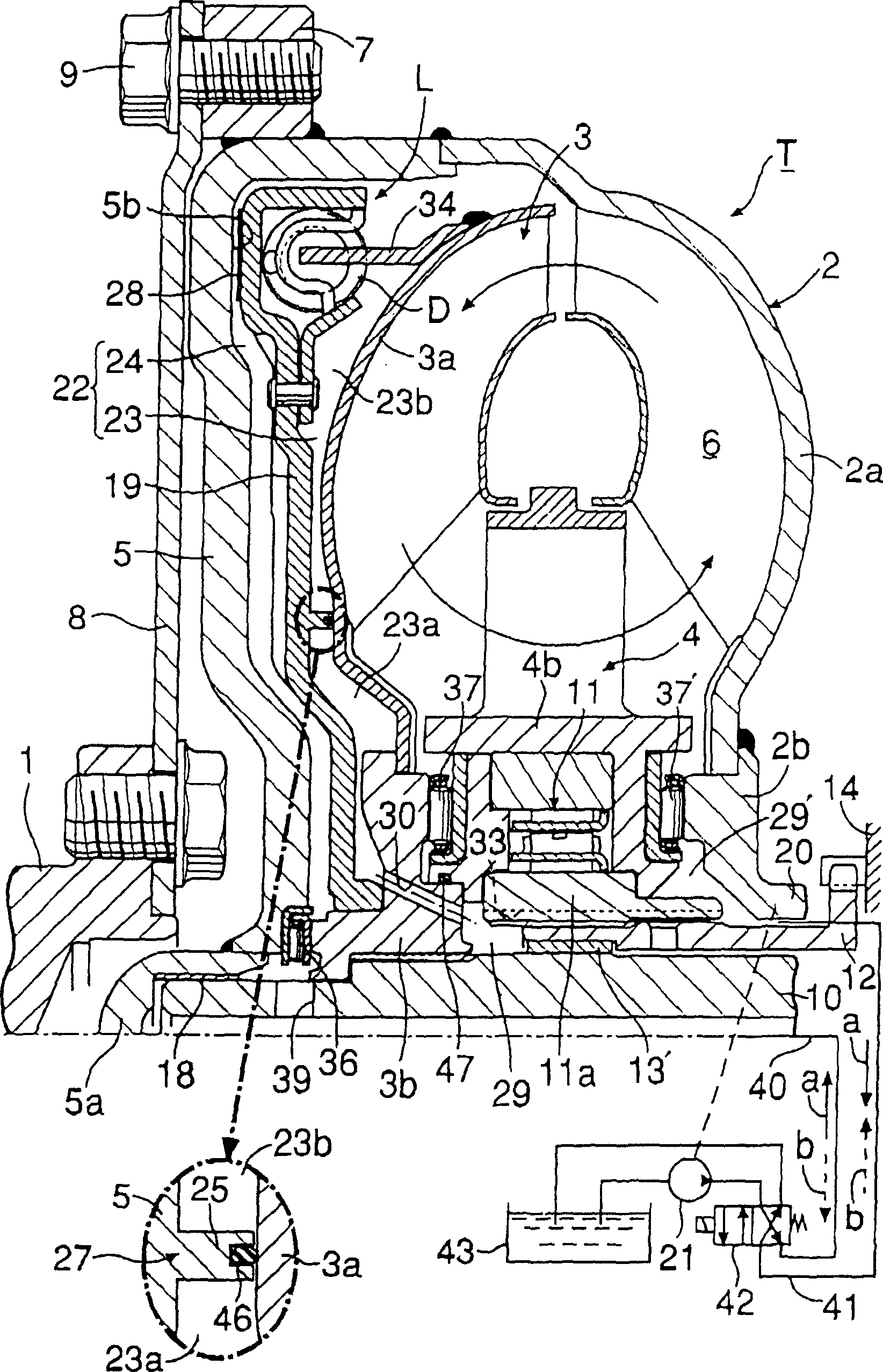

[0019] see figure 1 , the torque converter T as a hydraulic transmission device has a pump impeller 2 , a turbine rotor 3 opposite to the pump impeller 2 , and a stator 4 disposed between the inner periphery of the pump impeller 2 and the turbine rotor 3 . Between the three elements 2 , 3 and 4 is defined a circulation line 6 for transmitting power by means of working oil.

[0020] The side cover 5 is integrally connected to the casing 2 a of the pump impeller 2 by welding, and is used to cover the outer surface of the turbine rotor 3 . A group of connecting bosses 7 are arranged around and welded to the outer peripheral surface of the side cover 5 . A drive plate 8 matching a crankshaft 1 of an engine is fixed to the connection boss 7 by means of bolts 9 . A thrust needle bearing 36 is inserted between the hub 3 b of the turbine rotor 3 and the side cover 5 .

[0021] The output shaft 10 is disposed at the center of the torque converter T so as to be coaxial with the crank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com