Method for forming package spring string long belt

一种长带、螺旋弹簧的技术,应用在垫用弹簧或箱用弹簧,形成随后用作床垫或箱簧的包装弹簧串长带领域,能够解决承受不了高温等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

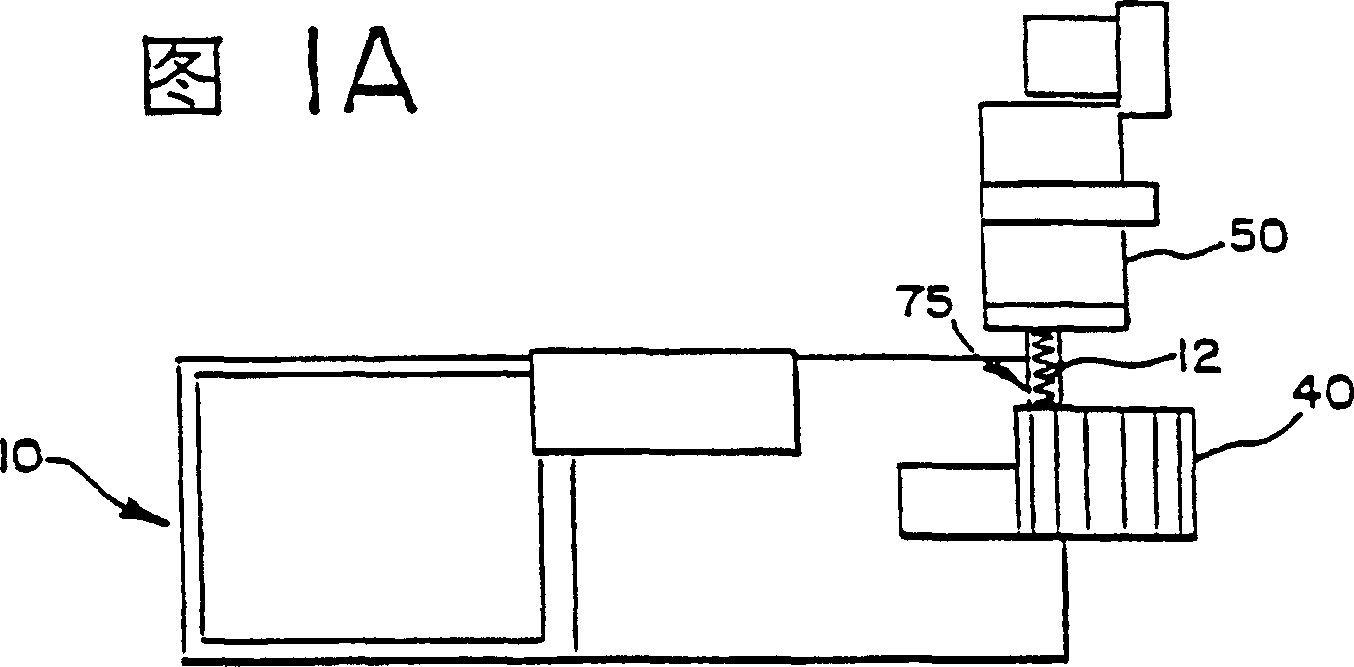

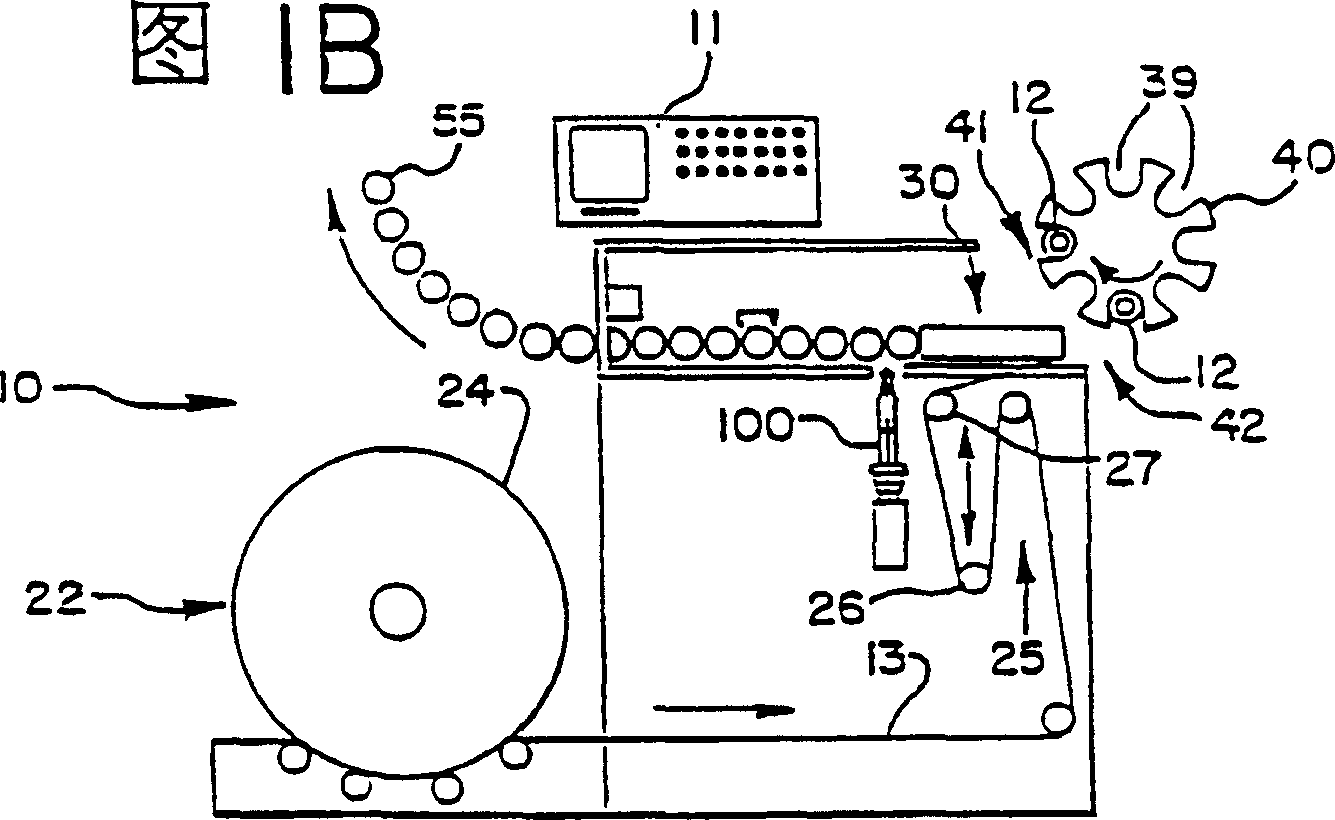

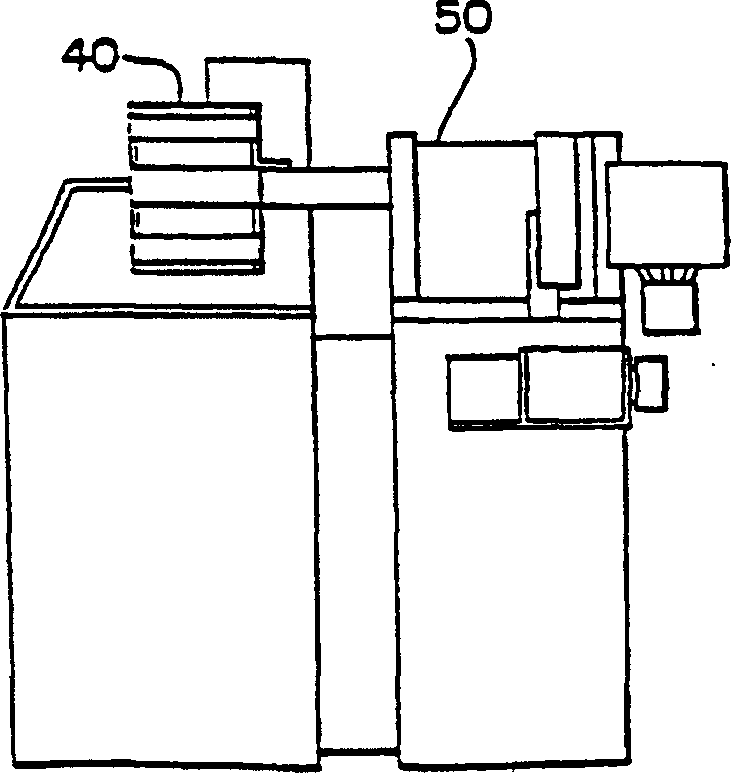

[0039] Referring now to the drawings, wherein like items are given the same reference numerals throughout, Figures 1A-1C illustrate an apparatus 10 of the present invention comprising a packaging material feeder 22 from which packaging material 13 is unwound from a drum 24, man-made or natural fabric Go around the tension adjustment roller 26 through the channel 25 to a transfer carousel 40 (cover is not shown in Fig. 1A-1C) capable of tempering the spiral wire rod, it is installed for generating rotation, and there are many grooves 39 above. The transfer carousel 40 is positioned at the slot filling station 41 to receive the untempered coil spring 12 from the winding head 50 . These coil springs are tempered, and this will be discussed later, and the coil springs 12 through the tempering coils enter the packaging manufacturing site 30 from the groove exit position 42 . Subsequently, a string of coil springs 12 packaging strips are formed from these tempered coil springs 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com