Process for increasing fodder/ fertilizer ratio of fodder level calcium hydrogen phosphate

A calcium hydrogen phosphate, feed-grade technology, applied in the field of feed-grade calcium hydrogen phosphate or rich calcium phosphate, can solve the problems that have not yet been seen, and achieve the effects of improving the recovery rate, increasing the ratio of feed and fertilizer, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

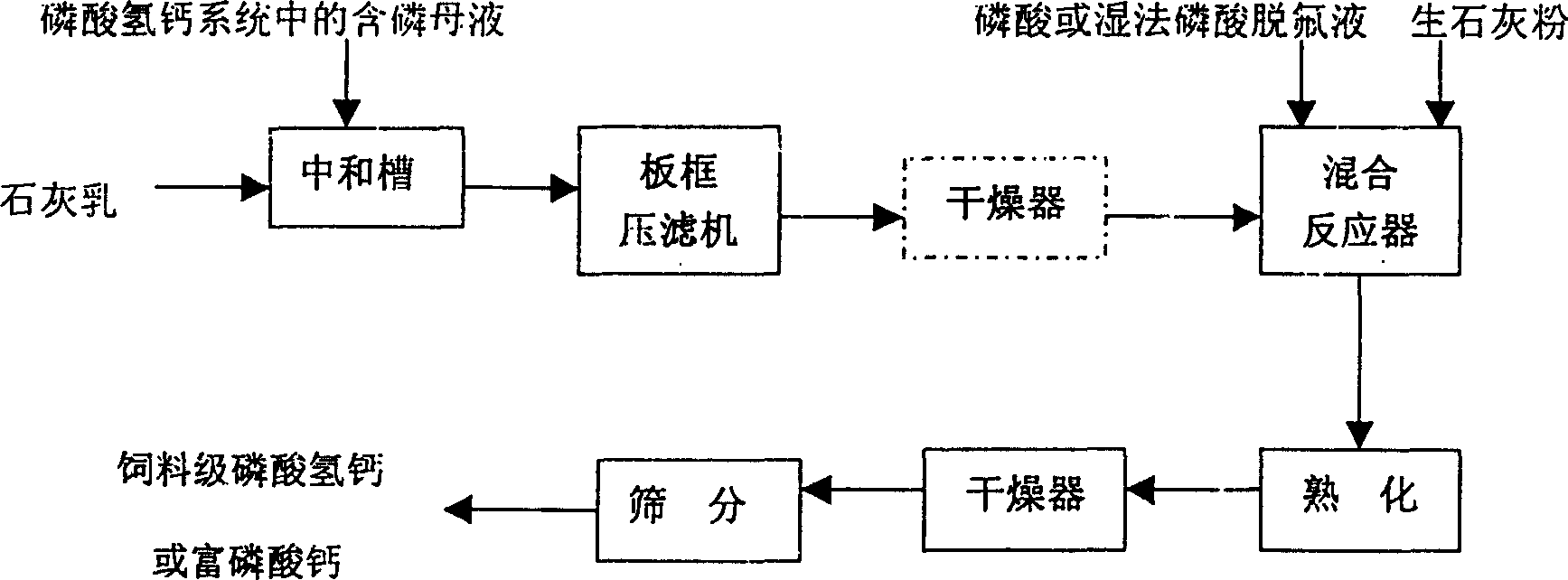

Image

Examples

Embodiment 1

[0027] Pump 2 / 3 height of phosphorus-containing mother liquor (including calcium hydrogen phosphate neutralization mother liquor, centrifuge mother liquor, tail gas washing liquid) into the stirring neutralization reaction tank of Φ2500×2800, and slowly add lime milk (specific gravity 1.05) to pH7.5, then keep stirring for 30 minutes, pump the well-reacted slurry to a plate-and-frame filter press for filtration, after filtering, the clear liquid pH7.3 contains 0.15 g / l of phosphorus (calculated as P), It can be discharged directly; get 315Kg of filter cake (water content 55%, P7.22%, Ca9.81%), mix this filter cake with 400Kg of dry calcium hydrogen phosphate, send it into the air dryer for drying, and get 536Kg of dry material (P16.2%, Ca20.75%, F0.169%). Add 150Kg of this material into the mixing reactor, 8Kg of 85% thermal phosphoric acid (diluted), stir well, add quicklime powder 2.8Kg, stir well, send to the storage yard for aging for 5 hours, dry and sieve to obtain calci...

Embodiment 2

[0031] Add 150Kg of the above-mentioned dried filter cake material into the mixing reactor, and add wet-process phosphoric acid defluorination solution (containing P 2 o 5 14.2%, F0.06%) 25Kg, add unslaked lime powder 2.5Kg after stirring evenly, send off slaking for 5 hours after stirring thoroughly, dry, sieve, obtain calcium hydrogen phosphate 157Kg, its quality index is as follows:

[0032] Phosphorus content (calculated as P) 17.15%, calcium content (calculated as Ca) 21.32%,

[0033] The fluorine content (calculated as F) is 0.16%, and the indicators of arsenic and lead are qualified.

Embodiment 3

[0035] Pump 2 / 3 height of phosphorus-containing mother liquor (including calcium hydrogen phosphate neutralization mother liquor, centrifuge mother liquor, tail gas washing liquid) into the stirring neutralization reaction tank of Φ2500×2800, and slowly add lime milk (specific gravity 1.05) to pH7.5, then kept stirring for 30 minutes, and the well-reacted slurry was pumped to a plate-and-frame filter press to filter, and after filtering, the clear pH was 7.3, containing 0.13g / l of phosphorus (in terms of P). Direct discharge; Obtain filter cake 380Kg (moisture 58%, P7.03%, Ca9.72%), this filter cake is added in the mixing reactor, adds 85% thermal process phosphoric acid 15Kg and 100Kg wet process phosphoric acid defluorination liquid (containing P 2 o 5 14.2%, F0.06%), after stirring for 2 hours, send to dry in the spray drier, sieve, obtain rich calcium phosphate 204Kg, its quality index is as follows:

[0036] Phosphorus content (calculated as P) 19.57%, calcium content (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com