Hydraulic swage press

A press and cold extrusion technology, applied in the direction of swaging press, upsetting press, forging press, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

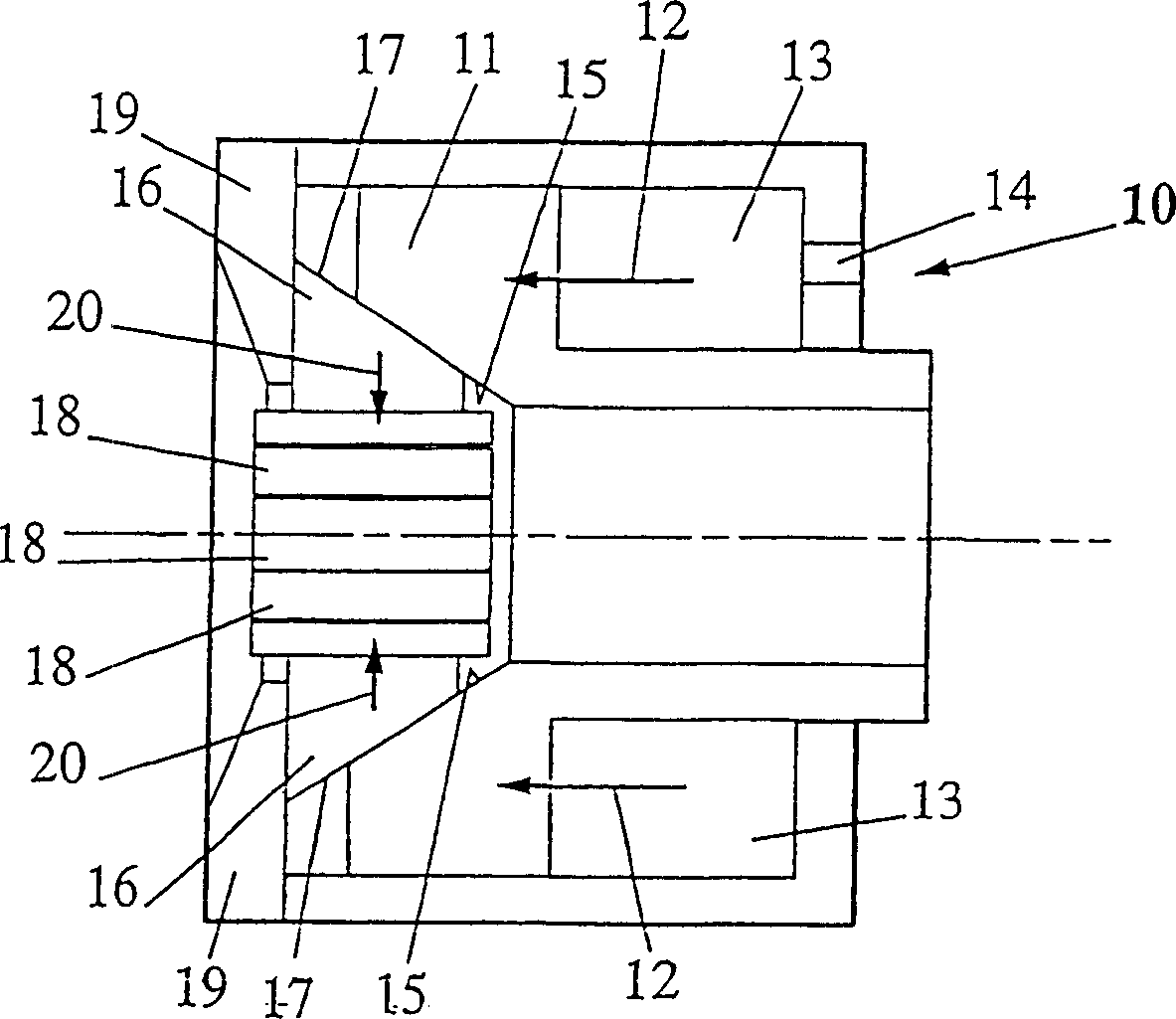

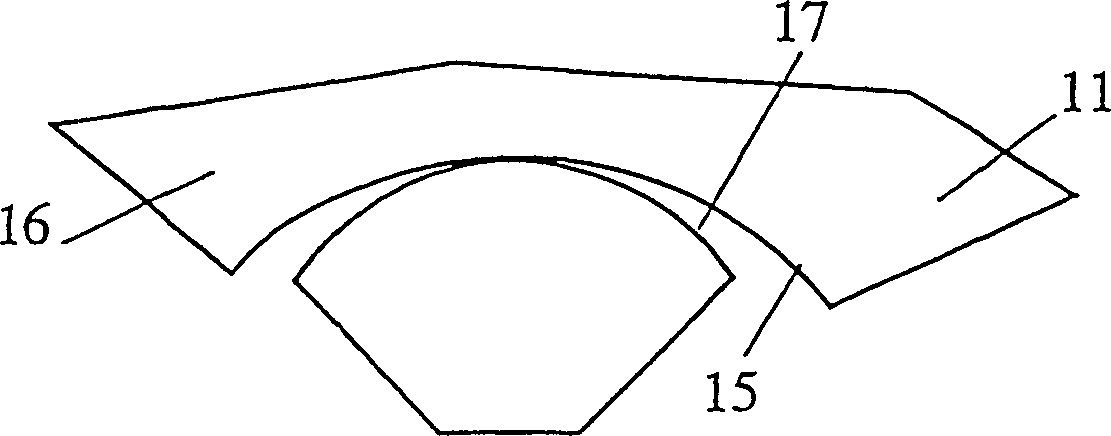

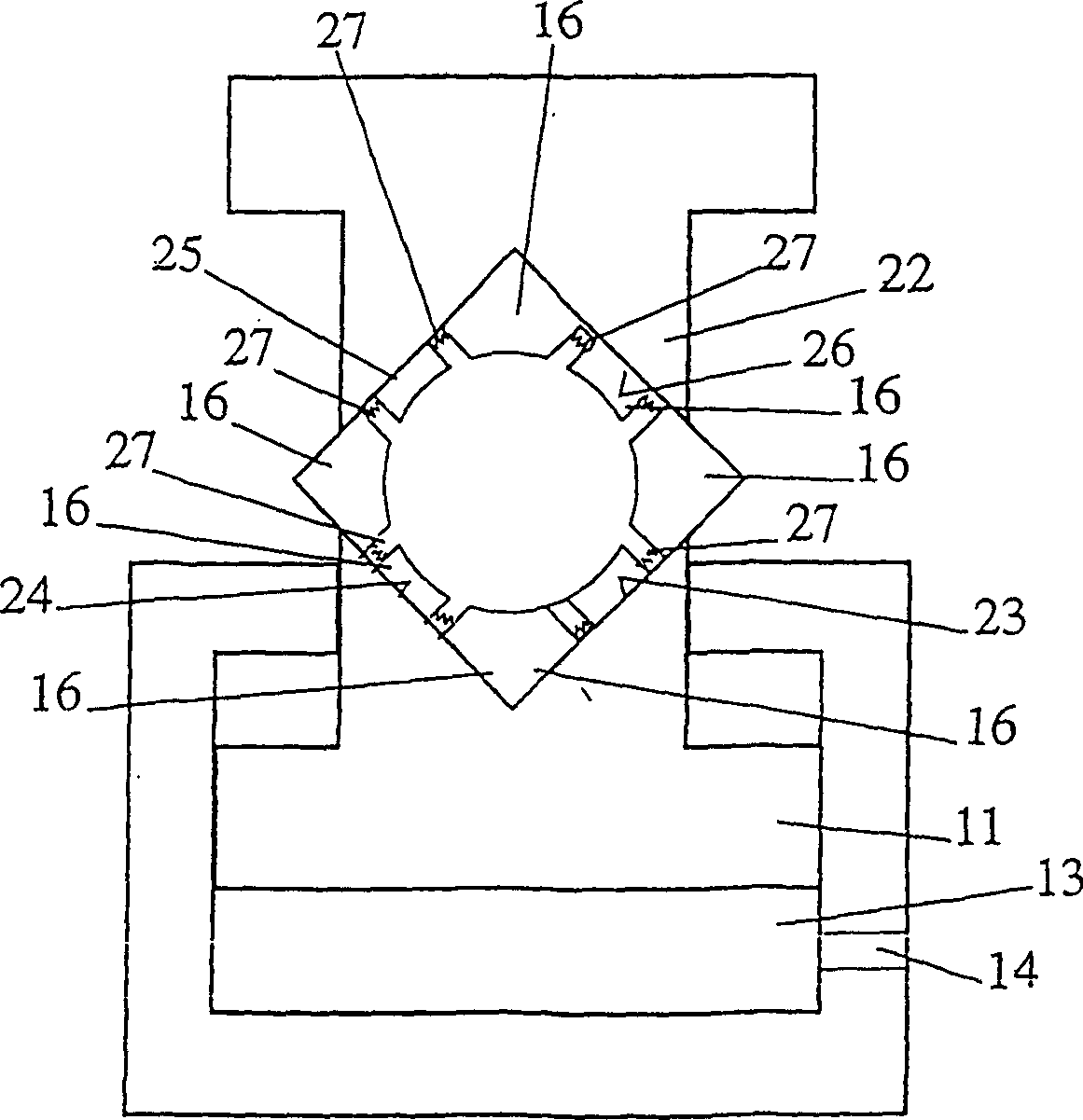

[0025] first reference figure 1 with Figure 1a , which shows a conventional type of conical cold extrusion press 10 using a working piston 11 driven in a forward direction 12 by pressurized liquid entering a chamber 13 through a hole 14 . The forward end face of the piston 11 is recessed to form a frustoconical surface 15 which cooperatingly engages a partial frustoconical surface 17 on a shoe 16, each of said shoe 16 With an inwardly facing pattern 18. The die shoe 16 is prevented from moving forward by the end wall 19 of the cold extruder assembly, at the end wall 19, when the piston 11 moves in the forward direction 12, the shoe 16 moves as shown by the arrow 20 Inward movement. Such as Figure 1a As shown, the bearing surface contact area between the mold shoe 16 and the frustoconical surface 15 of the piston 11 is almost a line contact due to its method of manufacture. Consequently, a reasonably long bearing area is required, which in turn leads to the requirement t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com