Lithium ion secondary battery and its manufacture method

A secondary battery, lithium ion technology, used in secondary batteries, electrolyte battery manufacturing, battery pack components, etc. The effect of large capacity, securing adhesive strength and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (production of positive electrode)

[0040] The use of 87 parts by weight LiCoO 2 , 8 parts by weight of graphite powder, 5 parts by weight of polyvinylidene fluoride dispersed in N-methylpyrrolidone (hereinafter referred to as NMP) positive electrode active material paste, coated with a thickness of about 300 microns to form a positive electrode active material film. An aluminum mesh with a thickness of 30 micrometers to be the positive electrode current collector 2 was placed on the top thereof, and a positive electrode active material paste adjusted to a thickness of 300 micrometers was applied again on the top thereof by the doctor blade method. After being left in a dryer at 60° C. for 60 minutes, it became semi-dry to form a laminate of the positive electrode current collector 2 and the positive electrode active material. The positive electrode 1 in which the positive electrode active material layer 3 was formed was produced by rolling the laminated body to a th...

Embodiment 2

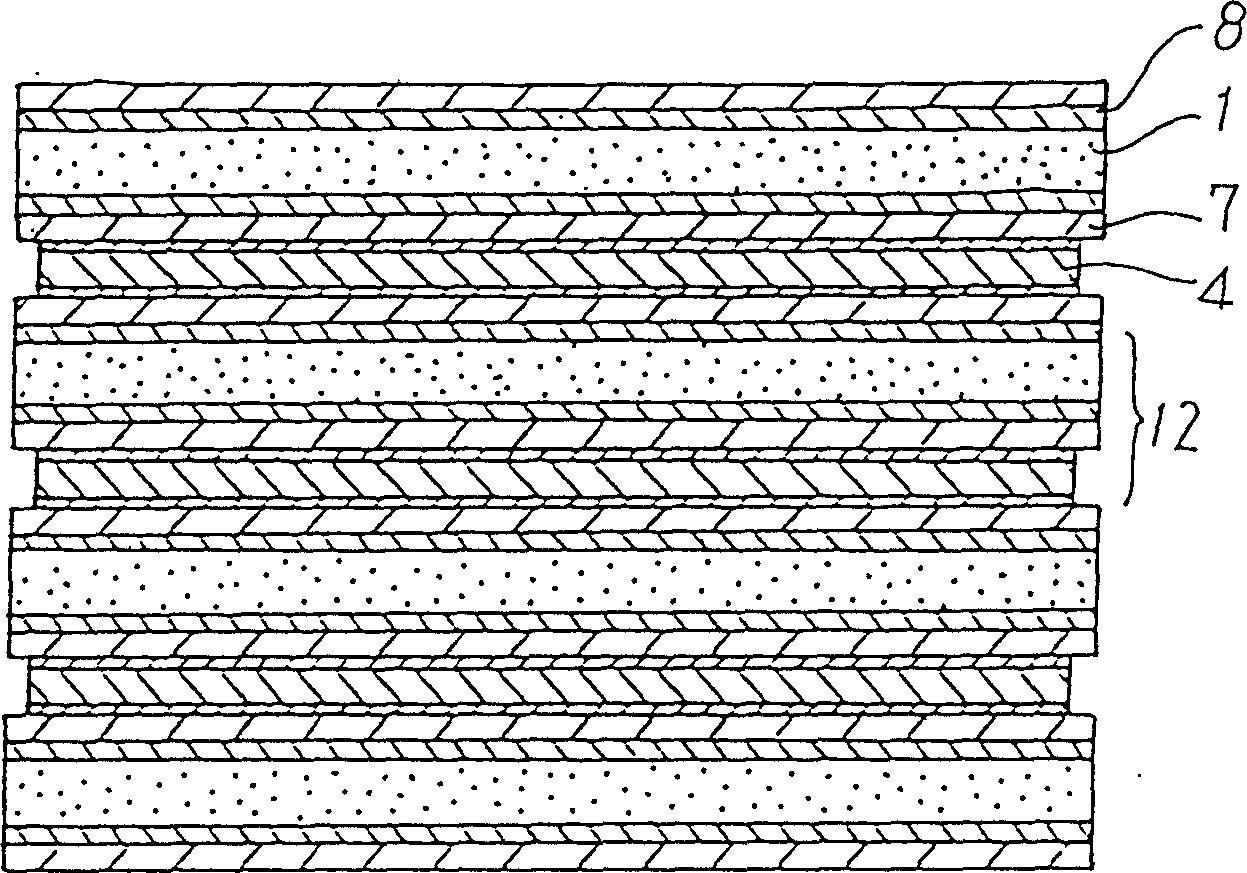

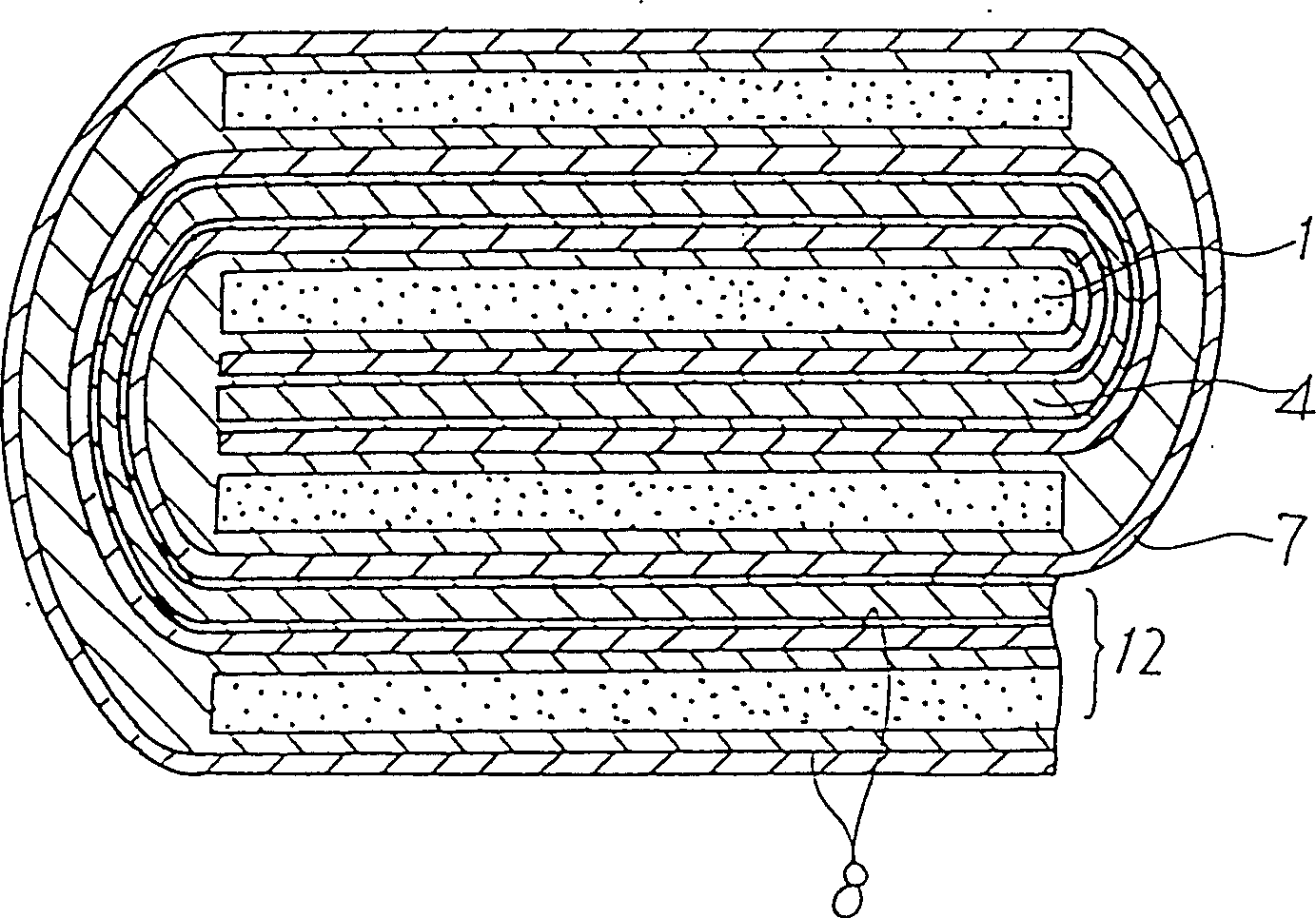

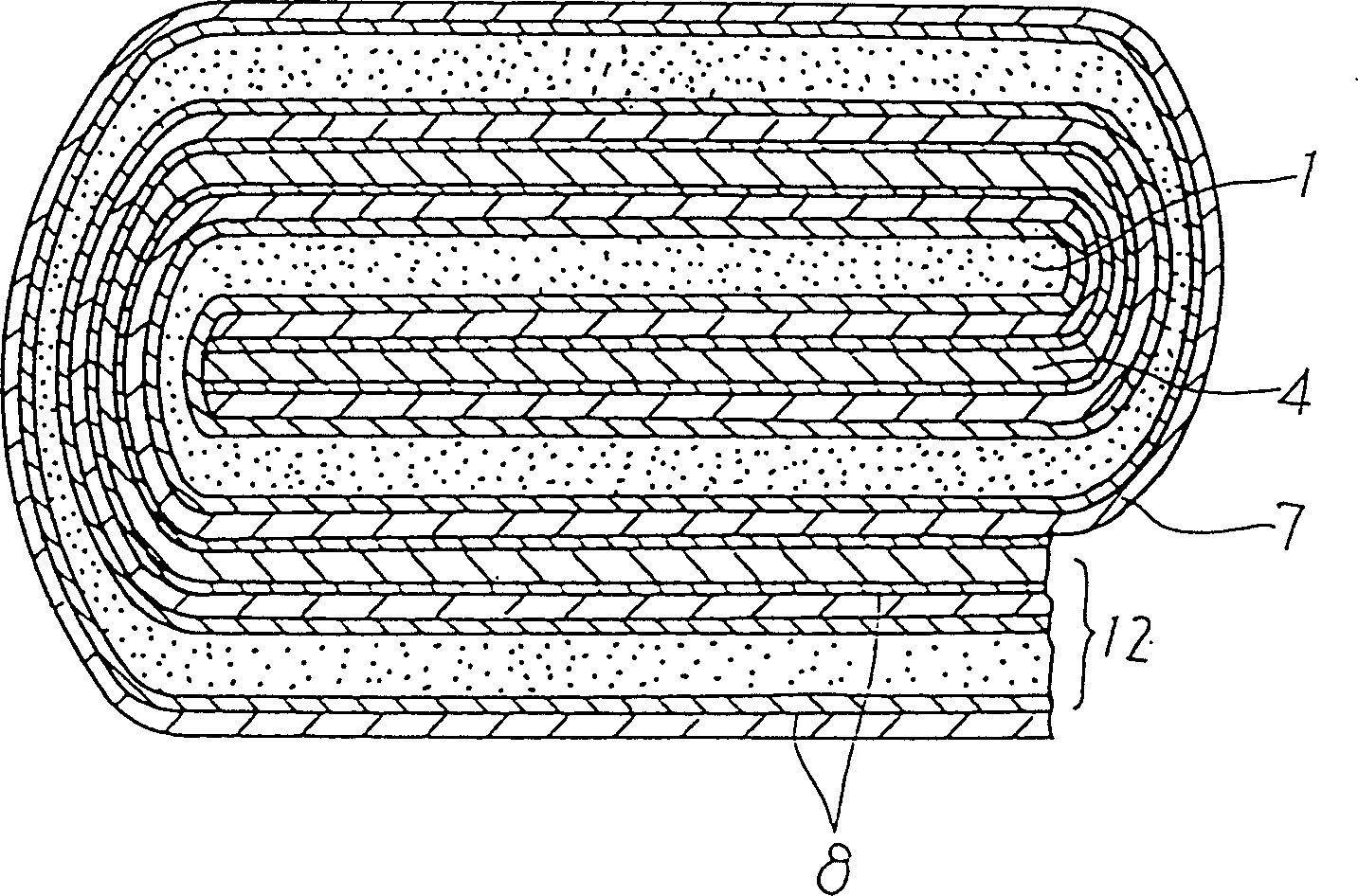

[0054] Only the adjustment of the adhesive of the above-mentioned embodiment 1 is changed as follows, and a figure 1 The battery body is shown as a flat laminated structure.

[0055] (adhesive adjustment)

[0056] With the average molecular weight (Mw) being 3.0 parts by weight of poly(acrylonitrile) (produced by Aldric company) of 86200, the average molecular weight (Ww) is 2.0 parts by weight of polyvinylidene fluoride (produced by Aldric company) of 534000, and the NMP of 95 parts by weight The composition ratio is mixed, and it is fully stirred to make it into a uniform solution to make a viscous adhesive.

Embodiment 3

[0058] Only the adjustment of the adhesive of the above-mentioned embodiment 1 is changed as follows, and a figure 1 The battery body is shown as a flat laminated structure.

[0059] (adhesive adjustment)

[0060] With average molecular weight (Mw) being 2.5 parts by weight of polyvinylidene fluoride (produced by Aldric company) of 180000, average molecular weight (Ww) is 2.5 parts by weight of polyvinylidene fluoride (produced by Aldric company) of 534000, and the NMP of 95 parts by weight Mix it according to the composition ratio, stir it sufficiently to make it into a uniform solution, and make a viscous adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap