Driving device, method and procedure of spray nozzle, liquid drop spray out device and its manufacturing method

A technology of a driving device and a driving method, which is applied to a printing device, an inking device, a device for coating liquid on a surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

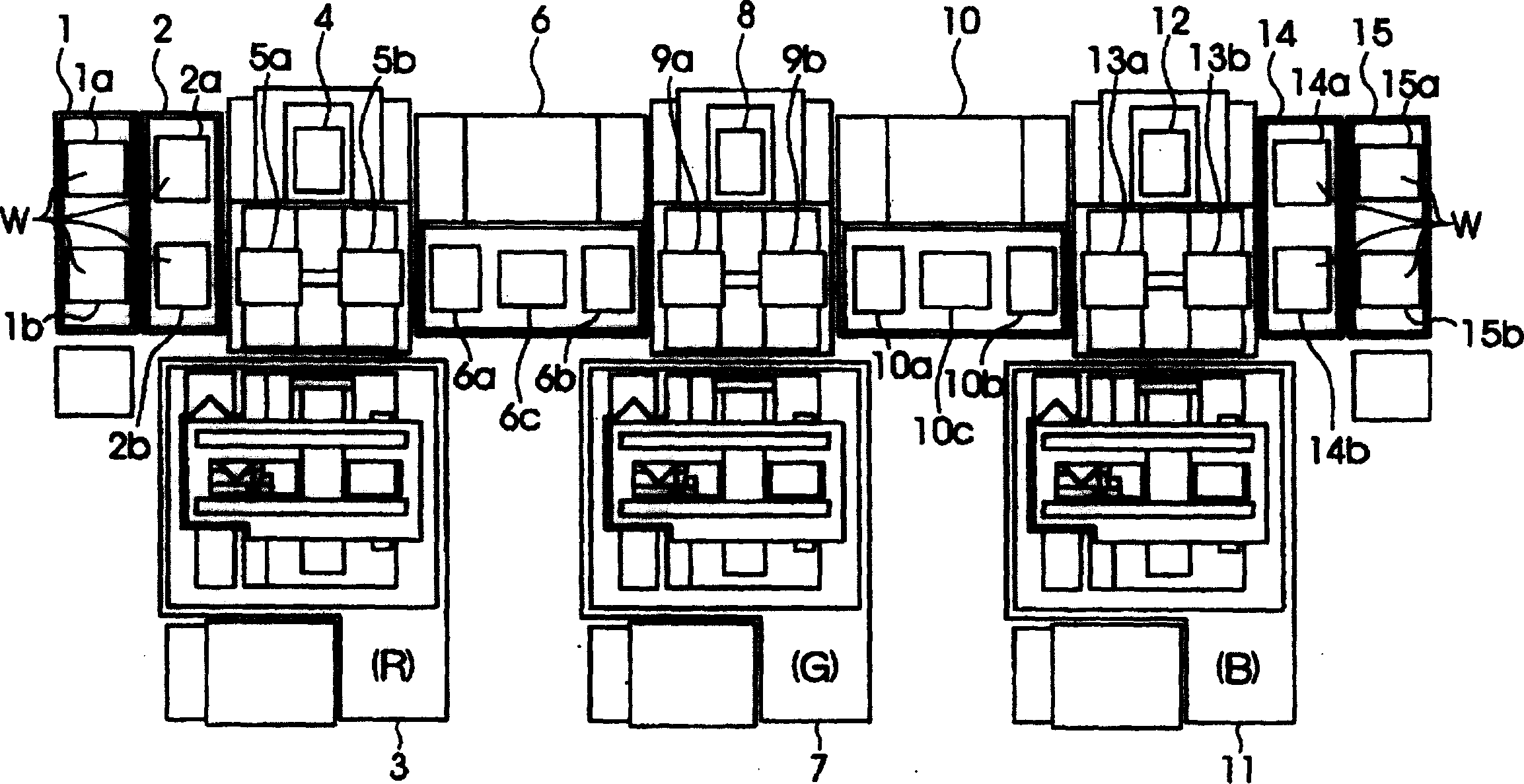

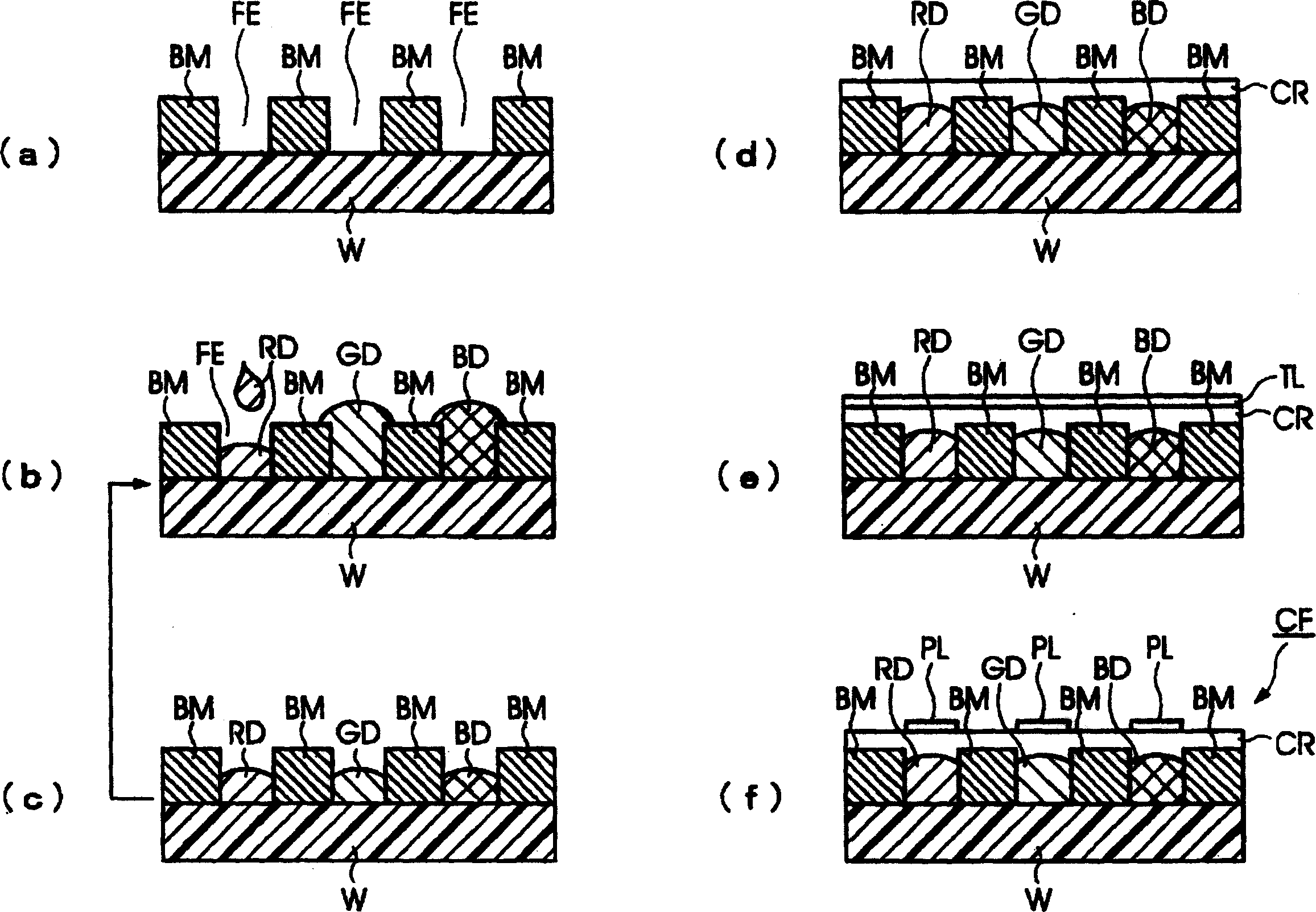

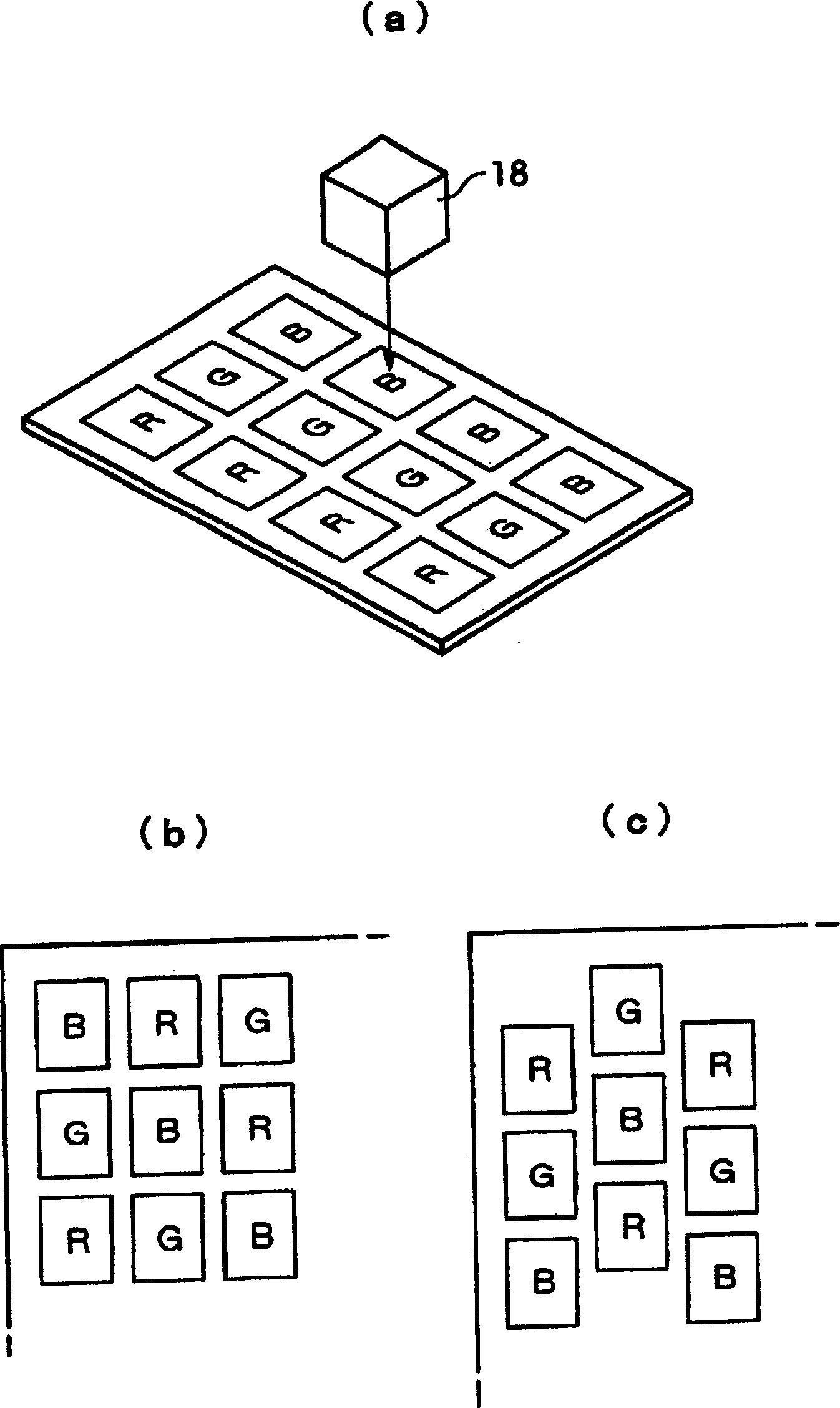

[0049] Referring to the accompanying drawings, a device and method for driving a nozzle, a device for ejecting droplets, a program for driving a nozzle, and a device manufacturing method and device according to an embodiment of the present invention will be described in detail below. In the following description, first, an example of a device manufacturing device having a droplet ejection device, a device manufacturing device used in manufacturing a device, a device manufactured using the device manufacturing device, and a device manufacturing method will be described, and then sequentially described. The nozzle driving device, the nozzle driving method and the nozzle driver program in the output device.

[0050] (Overall structure of device manufacturing apparatus having droplet ejection device)

[0051] figure 1 It is a plan view showing the overall structure of a device manufacturing apparatus including a droplet ejection apparatus according to an embodiment of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com