Method for producing building gypsum powder using phosphrus gypsum

A technology for making building gypsum powder and gypsum, which is applied in the field of making building gypsum from phosphogypsum. It can solve the problems of unreachable, low flexural and compressive strength, and fast initial setting time of building gypsum powder, so as to improve the flexural and compressive strength. , large production capacity, and the effect of prolonging the initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

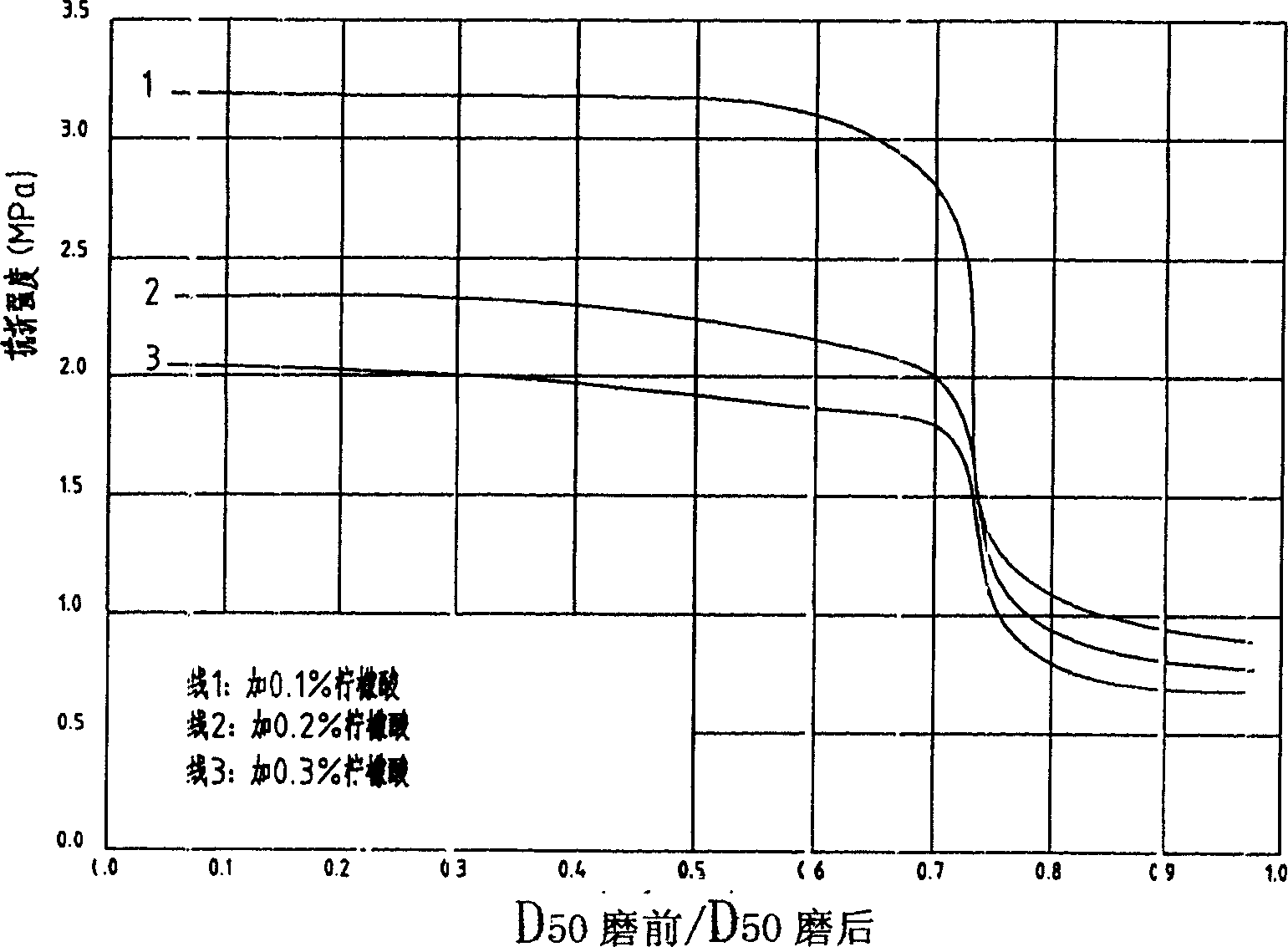

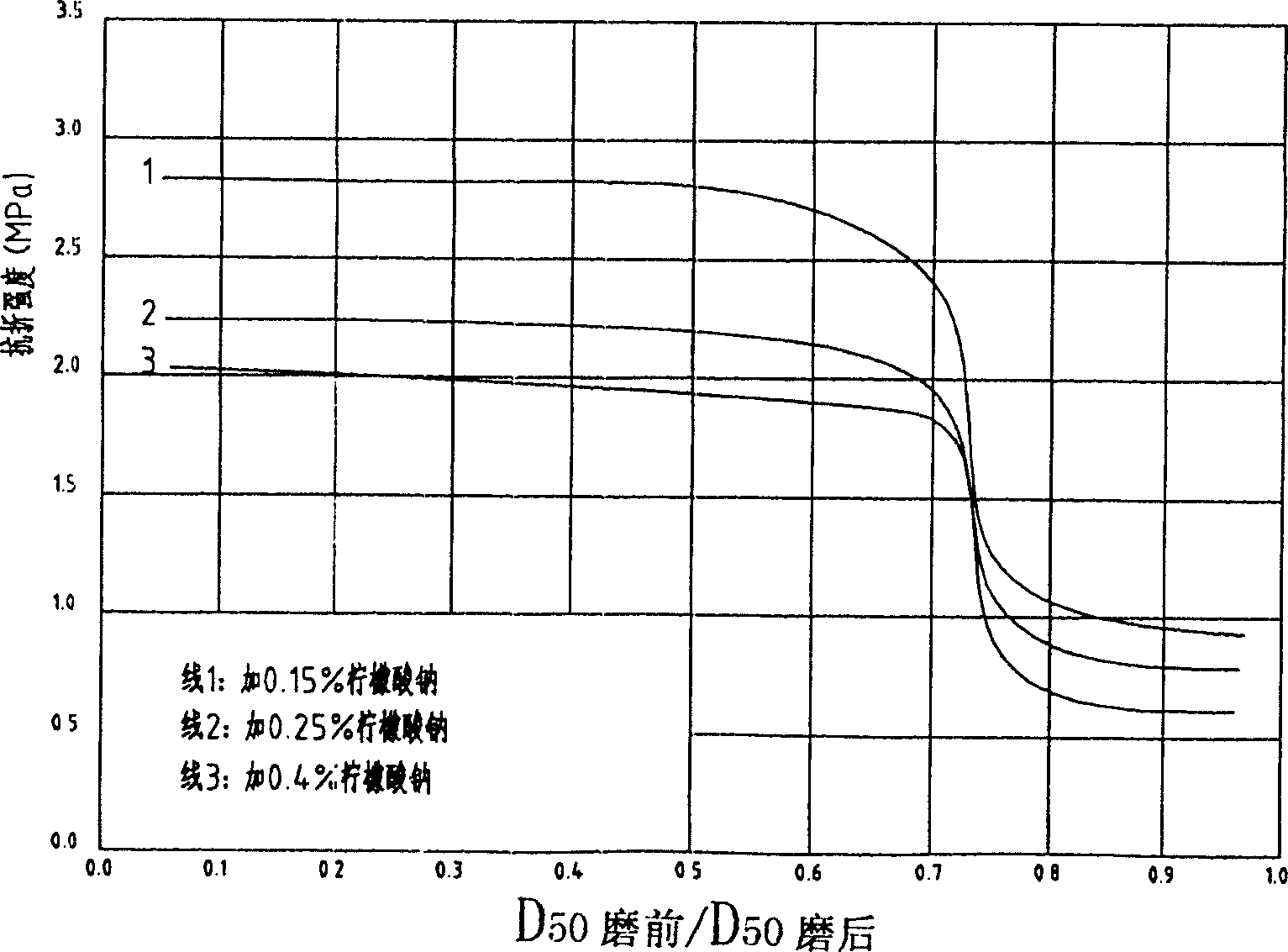

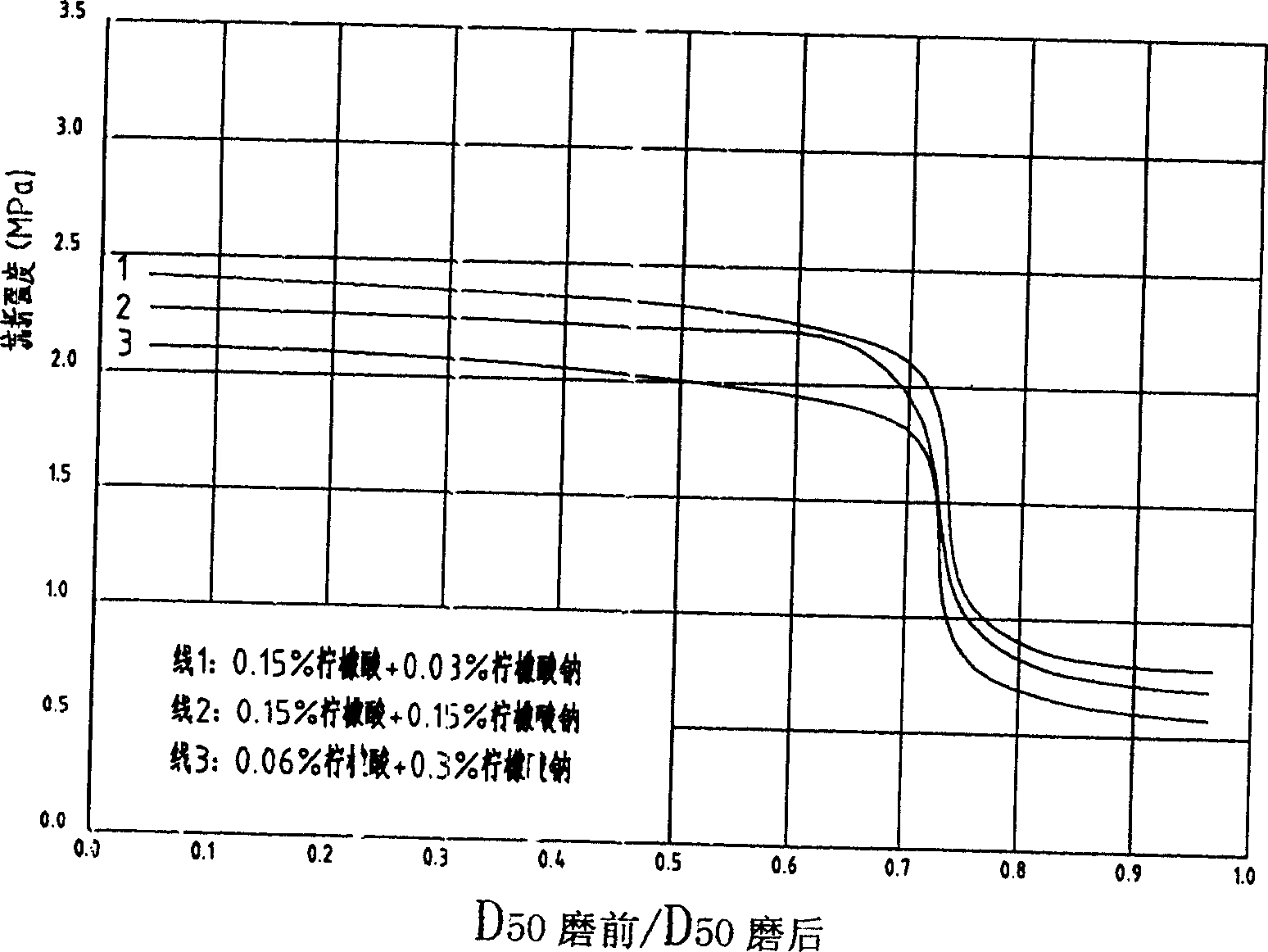

[0015] Example 1: The phosphogypsum by-product of wet-process phosphoric acid and the high-temperature flue gas at 400-700°C are sent to the dryer, and the phosphogypsum and the high-temperature gas are fully mixed in the dryer for calcination and dehydration, and are sent to the cloth bag with the airflow The dust collector is used for separation, and the temperature of the airflow at the inlet of the bag filter is controlled at 150-160°C. The calcined product collected by the bag filter is sent to the mill, and the additive citric acid is added to the mill at the same time. The amount of citric acid added The content is 0.1-0.22% of the weight of the calcined product, so that the D50 value of the pulverized product is reduced to 0.7 times of the D50 value of the calcined product before grinding, and the building gypsum powder is prepared. After testing, the initial setting time of the product is greater than 6 minutes, the final setting time is less than 30 minutes, the flexu...

Embodiment 2

[0016] Embodiment 2: by the method for embodiment 1, the D50 value of the product after grinding is reduced to 0.65 times of the D50 value of the calcined product before grinding, and the initial setting time of the prepared building gypsum powder is greater than 6 minutes, and the final setting time is less than After 30 minutes, the flexural strength is greater than 2.0Mpa, and the compressive strength is greater than 3.2Mpa, meeting the requirements of the national standard GB9776-88 for building gypsum powder.

Embodiment 3

[0017] Embodiment 3: by the method for embodiment 1, wherein the airflow temperature of bag filter inlet is controlled at 160-170 ℃, the additive that adds to mill is citric acid, and addition is 0.15-0.3% of calcined product weight, makes The obtained building gypsum powder has an initial setting time greater than 6 minutes, a final setting time less than 30 minutes, a flexural strength greater than 1.8Mpa, and a compressive strength greater than 3.0Mpa, meeting the requirements of the national standard GB9776-88 for building gypsum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing time | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com