Granulation method of large particle urea

A large-granule urea and granulation technology, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of poor product color, complex process flow and high operating cost, and achieve good color and luster, good cooling effect and operating cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

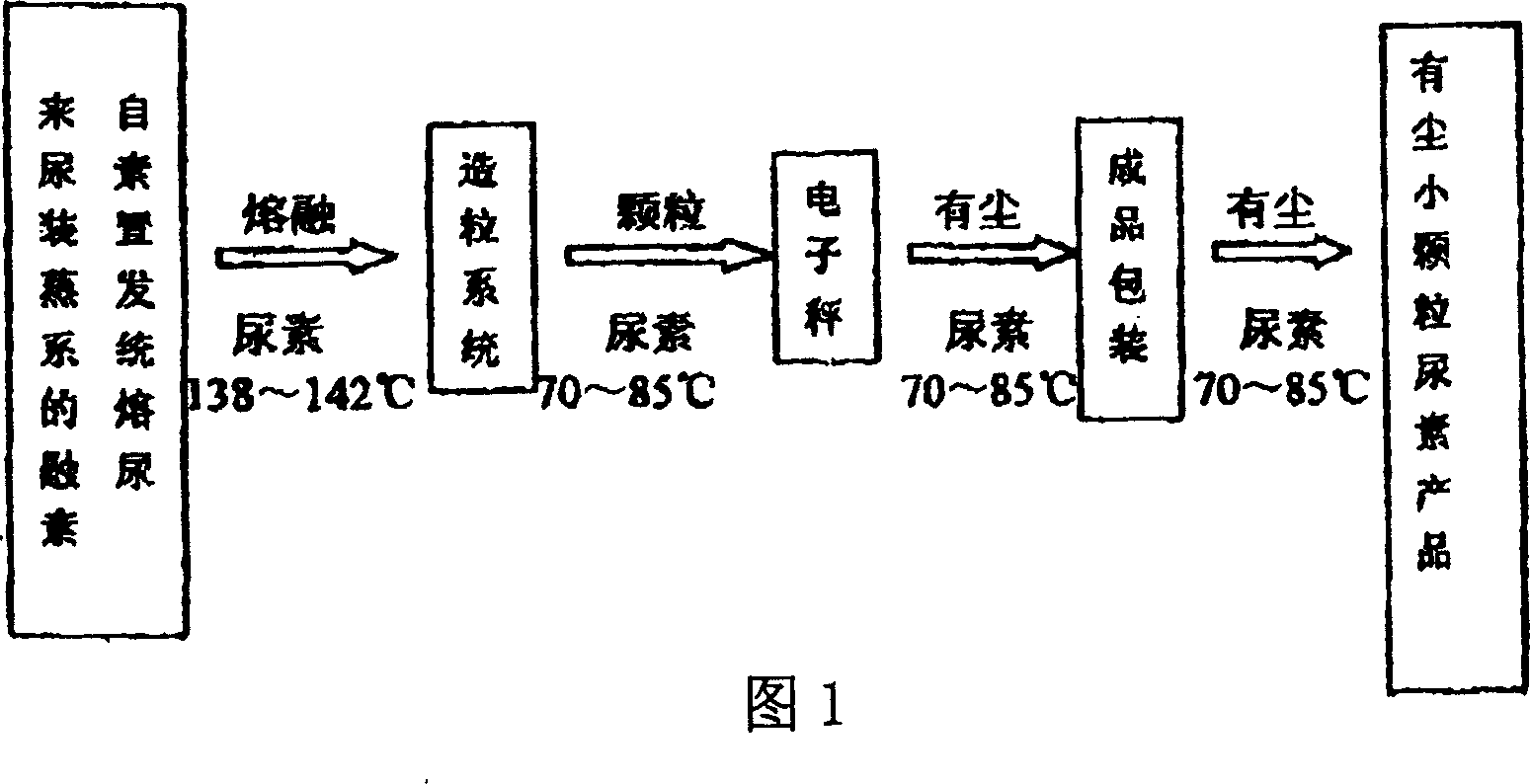

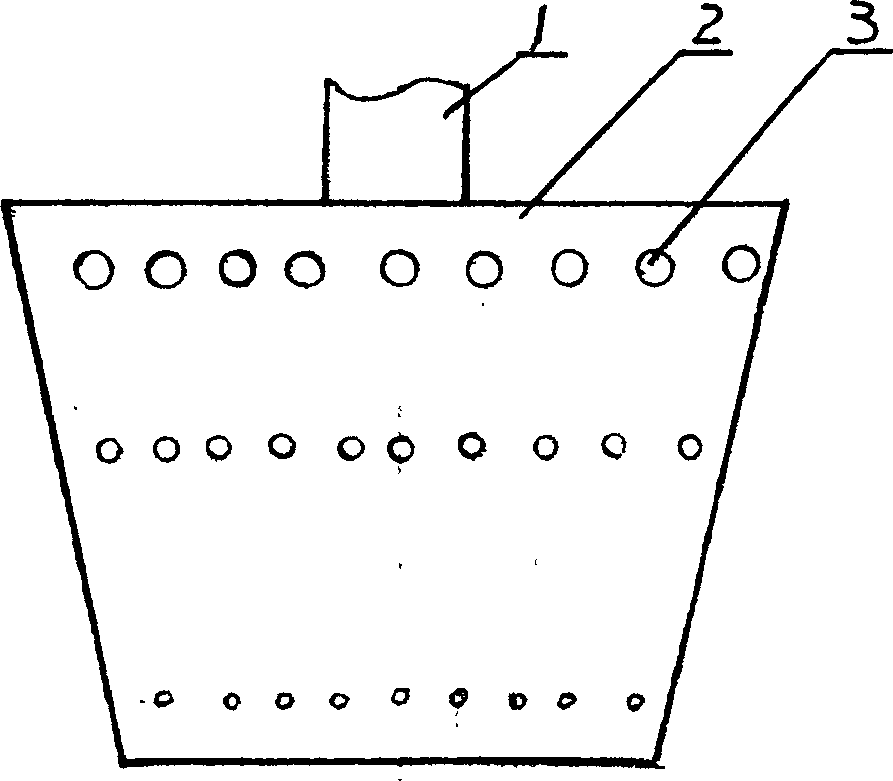

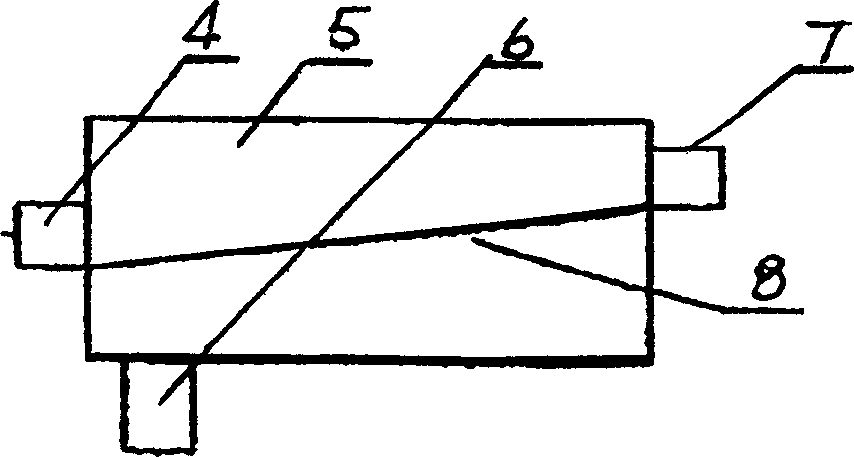

[0023] see Figure 2 to Figure 5 .

[0024] The invention includes three parts, namely granulation, urea granule cooling and dust removal, and recovery of urea dust. Wherein, granulation and urea particle cooling and dedusting are the core content of the present invention, and the recovery of urea dust is only a supporting technical measure.

[0025] The large particle urea granulation method comprises the following steps

[0026] (1) Use the improved granulation nozzle to spray and granulate molten urea with a temperature of 138-142°C. The particles are cooled and solidified by the prilling tower, and the temperature drops to 70-85°C to form solid urea with a particle size of 1.6-2.8mm. particles;

[0027] (2) The solid urea particles are sent to the gas-solid heat transfer and dust removal device, and the cold air is fluidized and dedusted and cooled to remove small particle size dust. The temperature of the solid urea particles is reduced to 40-50°C, and it becomes a dus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com