Method and device for ceramising base glass of glass ceramic

A glass-ceramic and ceramization technology, applied in glass production, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of heating the substrate glass, such as high heat and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

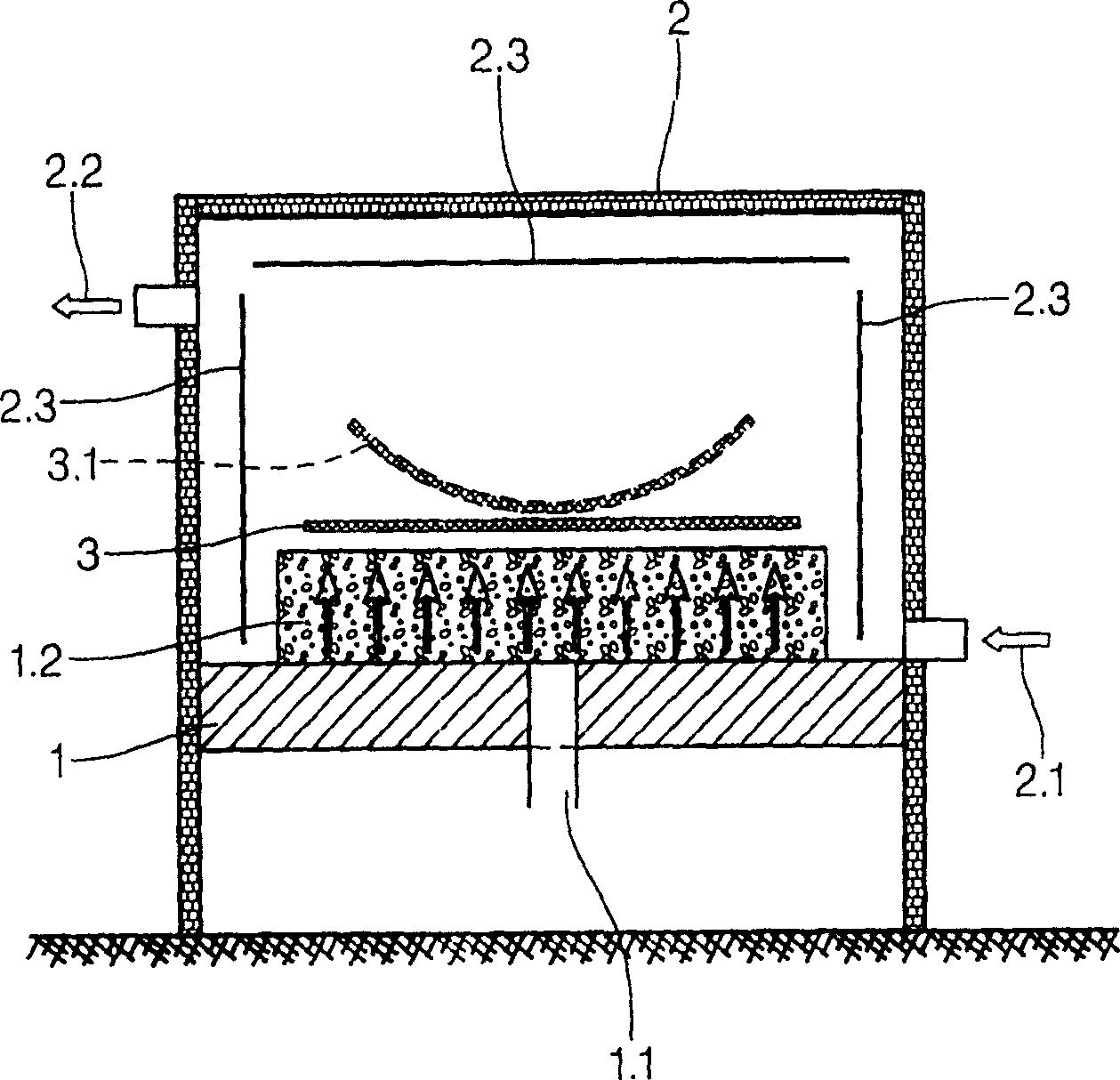

[0043] figure 1 A pallet 1 is shown as a floating base. The support plate 1 supports a diaphragm 1.2 made of porous material. The carrier plate 1 and the membrane 1.2 are located in a housing 2 with an air inlet 2.1 and an air outlet 2.2. The pallet 1 has a gas connection 1.1. A base glass 3 in the form of a glass pane is located above the membrane 1.2.

[0044] The housing 2 encloses a wall 2.3 with strong IR reflective properties. The device includes an array of IR rays, not shown here.

[0045] The gas passing through the openings of the diaphragm 1.2 is introduced through the gas connection 1.1. An air cushion is formed between the upper surface of the membrane 1.2 and the lower surface of the preform 3 . The preform spins on this air cushion until the ceramization time is complete.

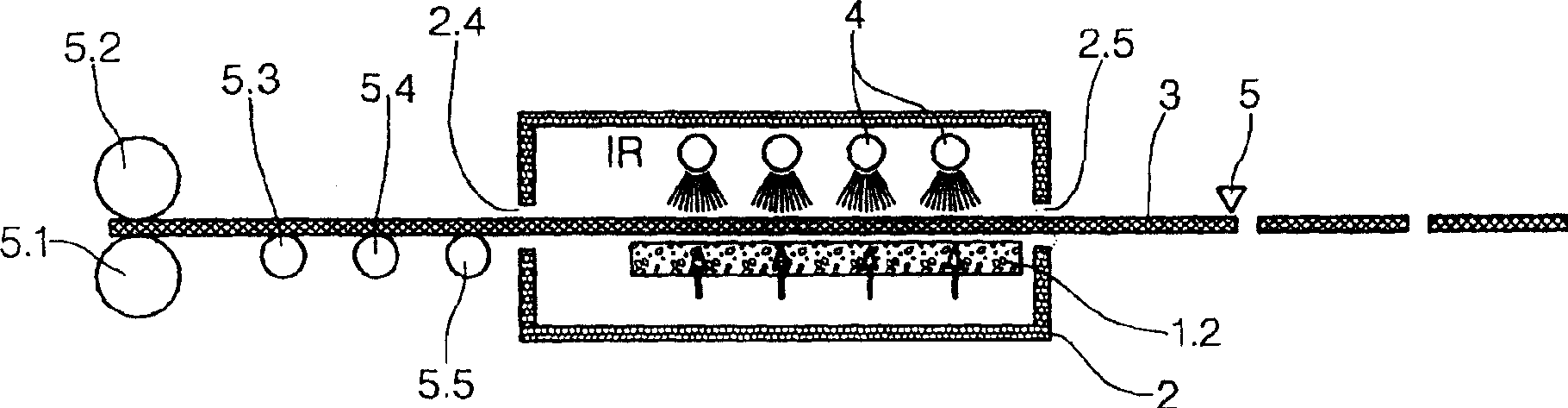

[0046] The device is suitable for both batch and continuous operation. The housing 2 can also be designed as an elongated chamber with the inlet on one front side and the outlet on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com