Candidda maltosa CGMCC No.0693 and its use in petroleum refinement

A technology of Candida and Candida, which is applied in the direction of microorganism-based methods, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of dewaxing, poor demulsification effect, long production time per unit oil product, and low production efficiency. Low efficiency and other problems, to achieve the effects of easier demulsification, shorter dewaxing time, and lower unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

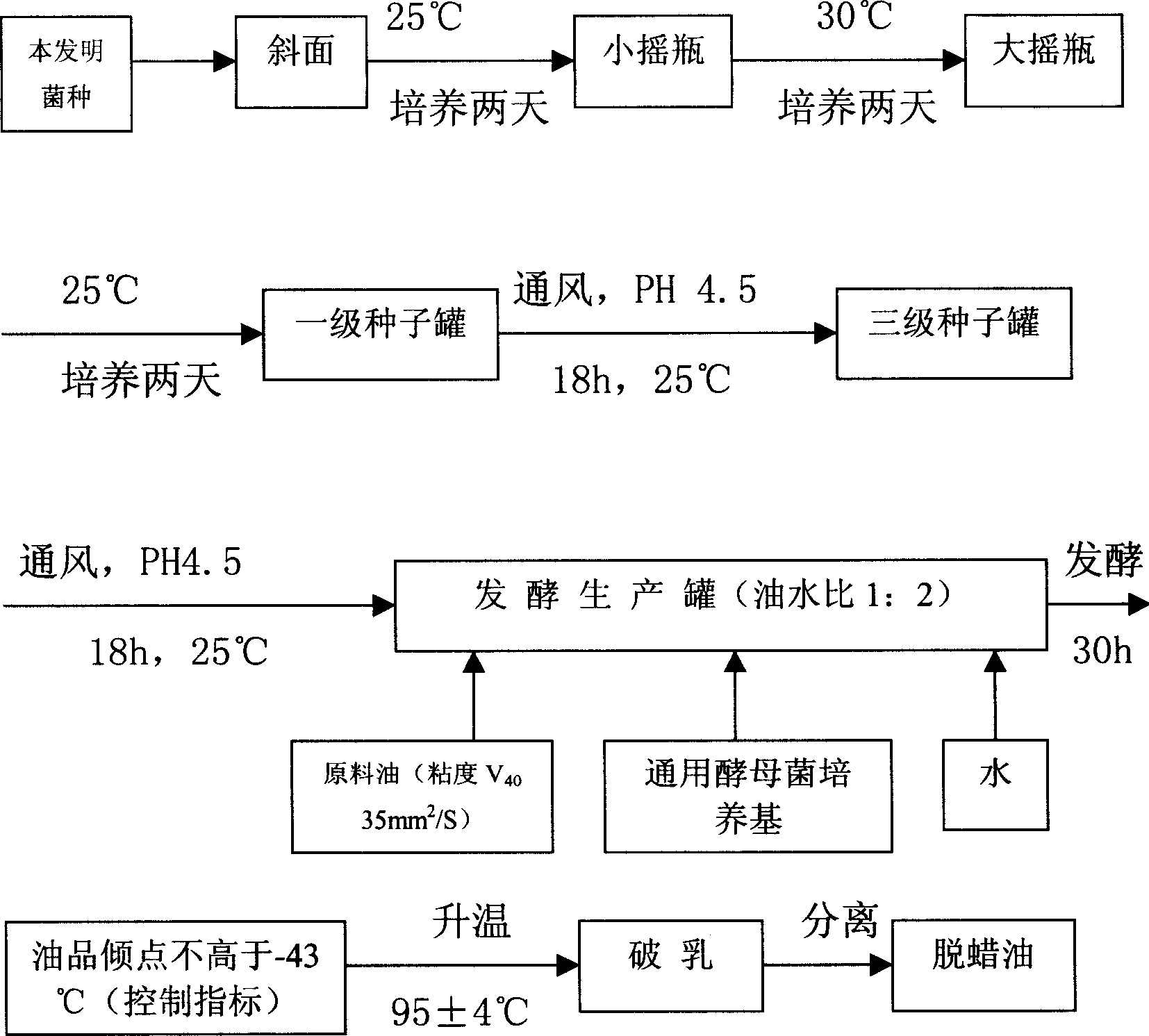

[0038] Embodiment one: according to the attached drawing figure 1 Process operation to obtain 45# transformer oil base oil.

[0039] In a sterile room, transfer the yeast of the present invention to a small shake flask, a large shake flask, a first-stage tank, and a third-stage tank for five-stage culture and proliferation, and connect it to a fermenter containing raw material oil. After 30 hours of fermentation, take a sample to measure the freezing point Qualified, stop the tank, demulsify, settle, and centrifuge to obtain low freezing point 45# transformer oil base oil and petroleum yeast waste liquid.

Embodiment 2

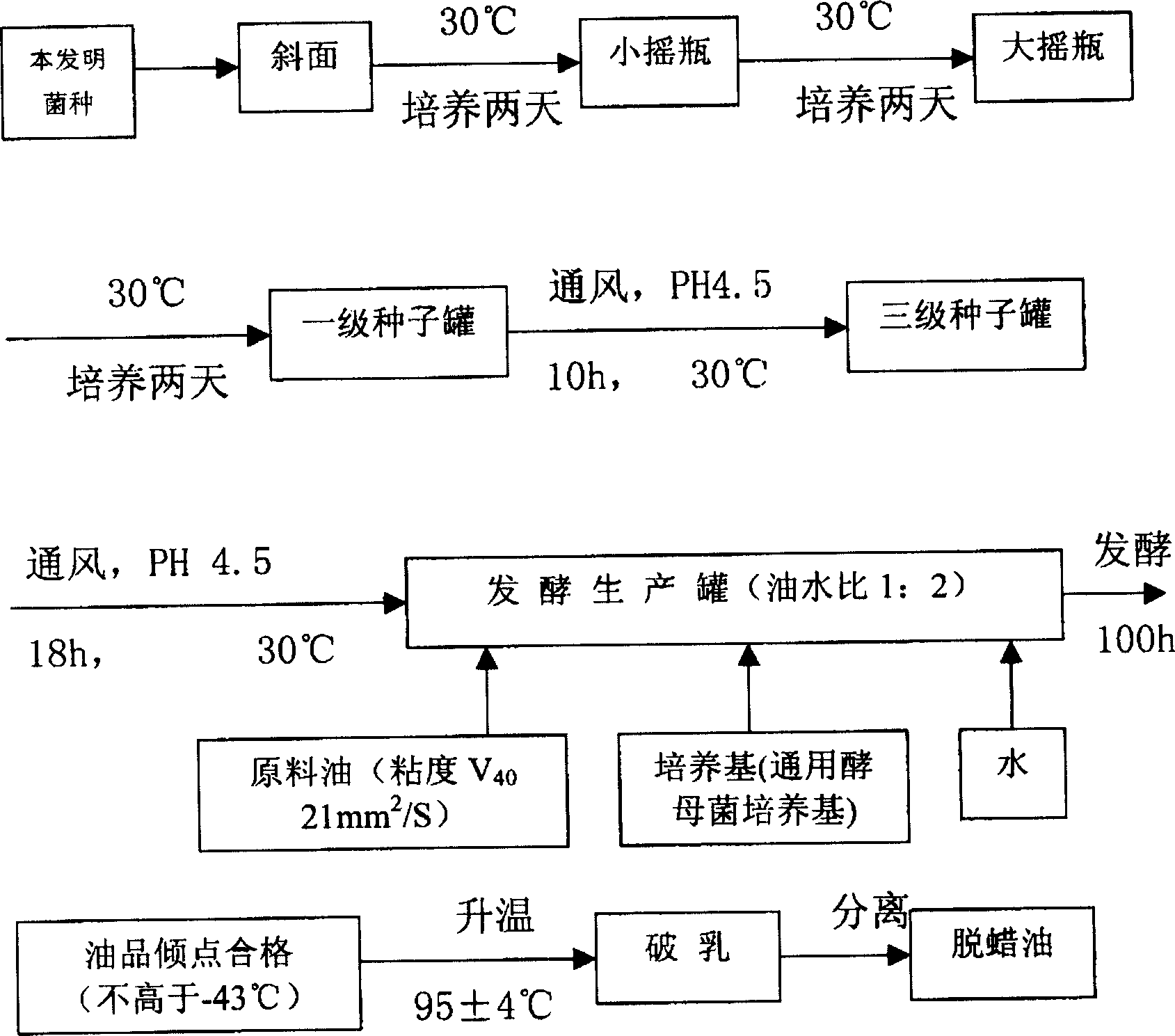

[0041] According to the attached picture figure 2 Process flow operation to obtain 22# refrigerating machine oil base oil.

[0042] In the sterile room, the yeast was transferred to small shake flasks, large shake flasks, first-level tanks, and third-level tanks for five-level culture and multiplication, and then connected to the fermentation tank containing raw material oil. After 100 hours of fermentation, sampling and measuring pour point passed , stop the tank, demulsify, settle, and centrifuge to obtain low freezing point 22# refrigerating machine oil base oil and petroleum yeast waste liquid.

Embodiment 3

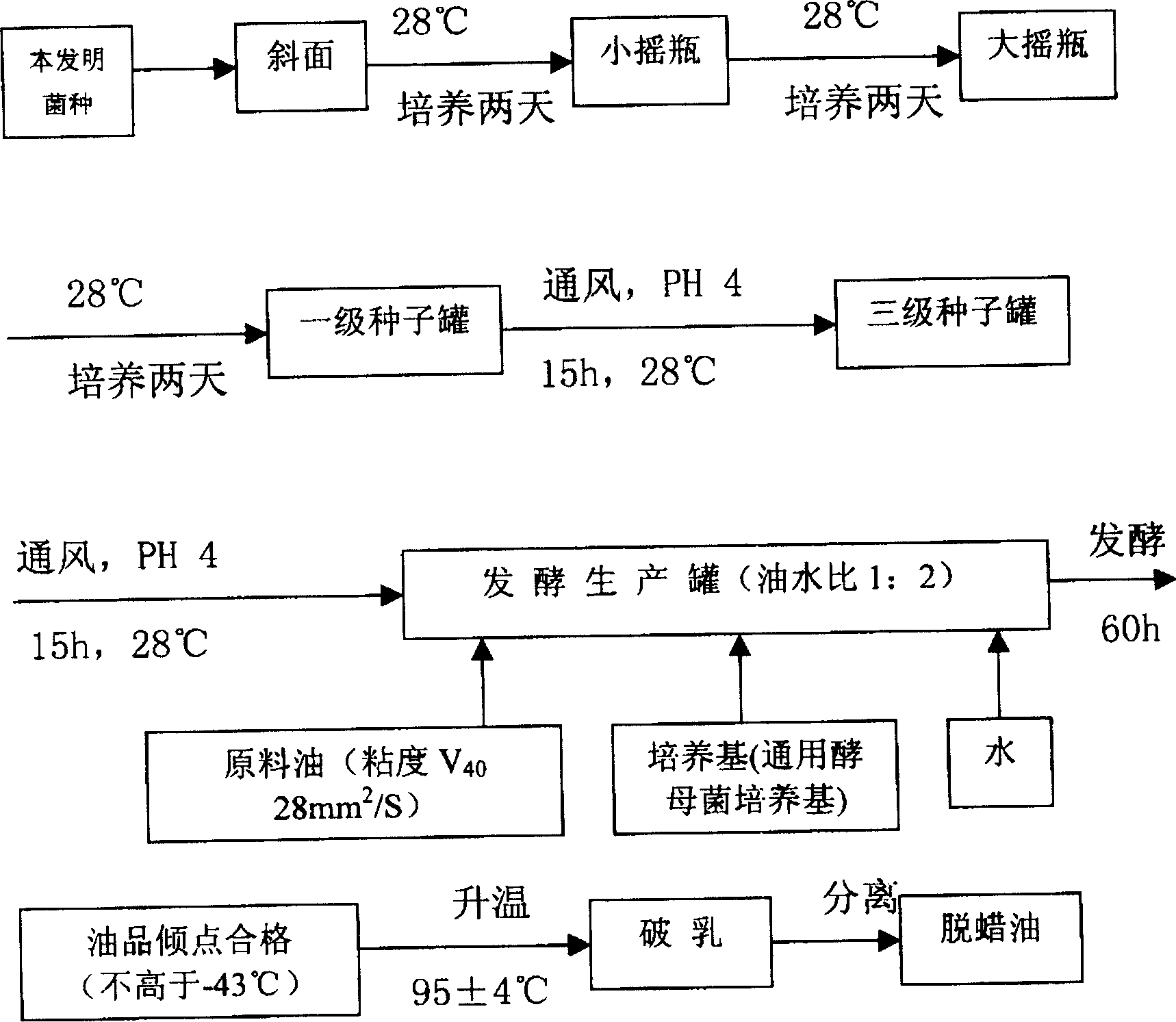

[0044] According to the attached picture image 3 Process flow operation to obtain 32# refrigerating machine oil base oil.

[0045] In the sterile room, the yeast was transferred to small shake flasks, large shake flasks, first-level tanks, and third-level tanks for five-level culture and proliferation, and then connected to a fermentation tank containing raw material oil. After 60 hours of fermentation, sampling and measuring pour point passed , stop the tank, break the emulsion, settle, and centrifuge to obtain low freezing point 32# refrigerating machine oil base oil and petroleum yeast waste liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com