Workpiece or tool holders

A fixture and tool technology, applied in the field of fixtures for workpieces or tools, can solve the problem of impossible to use clamping devices, and achieve the effects of sufficient strength, good repeatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

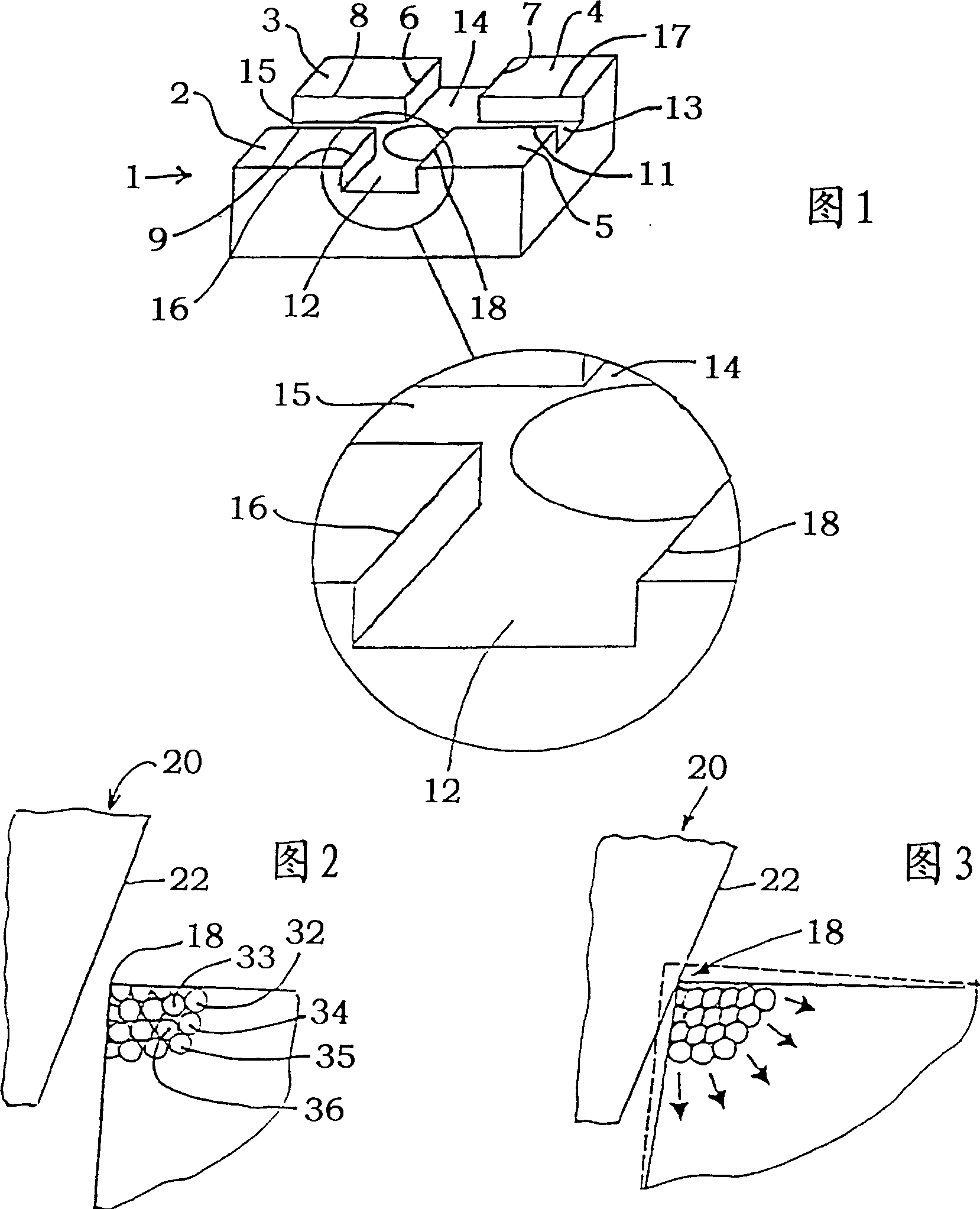

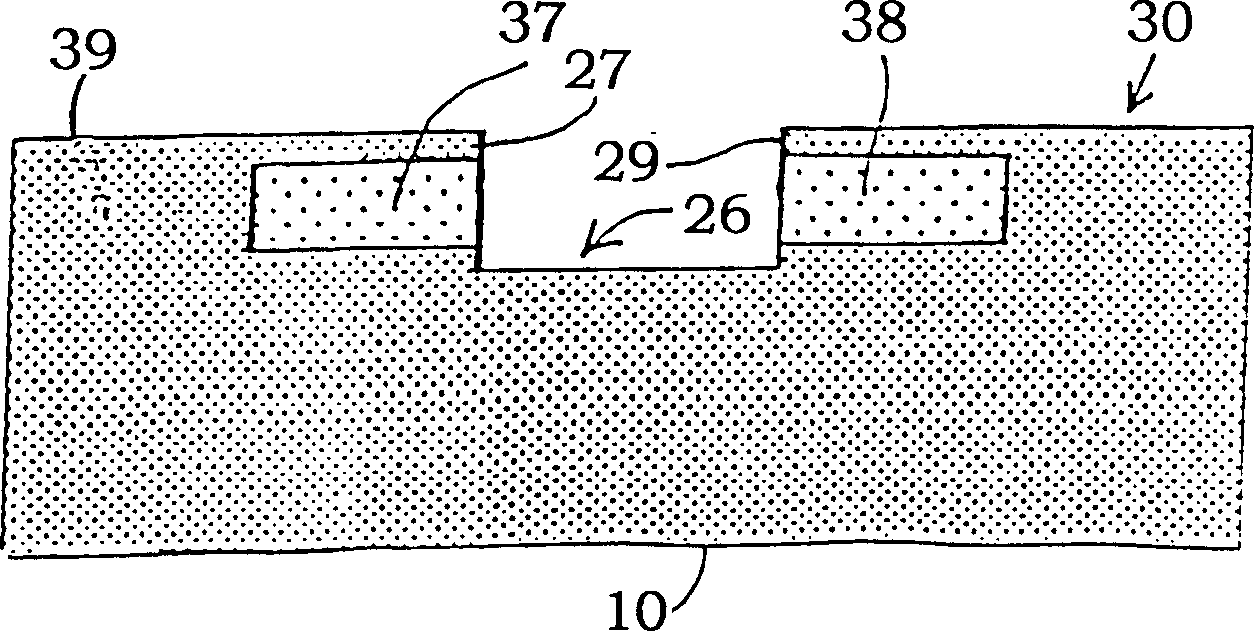

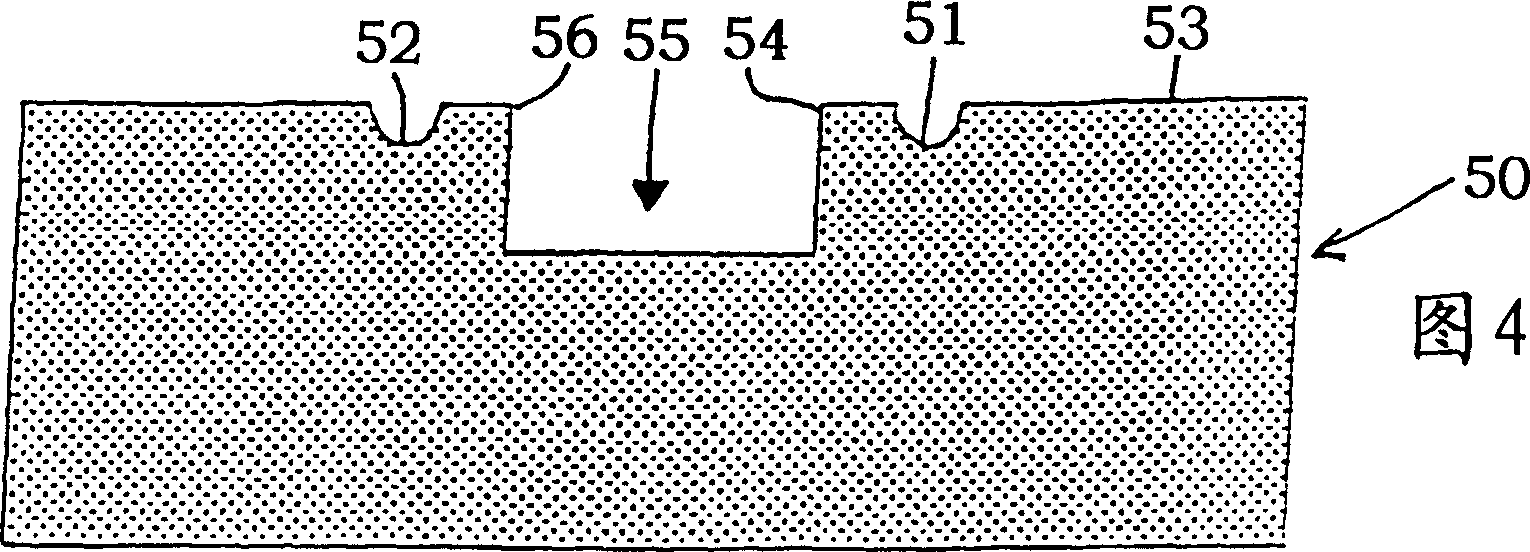

[0022] The holder, generally designated 1 , consists essentially of sintered tool steel, is square in plan view and has a substantially planar outer surface formed by four parts 2 , 3 , 4 and 5 lying in one plane. 10( Figure 8 ) permanently fixes a workpiece or a tool to be machined, such as an electrode for electroerosion machining. Sections 2, 3, 4 and 5 are separated from each other by grooves 12, 13, 14 and 15 made therefrom in the jig. Each groove has a right-angled cross-section with substantially planar groove sides and is arranged crosswise so that two opposing grooves 12 and 14 or 13 and 15 are respectively aligned. The groove width of all the grooves is the same, so that the parallel edges 16, 18 of the opposite groove 12, the parallel edges 11, 17 of the opposite groove 13, the The parallel edges 6, 7 and the parallel edges 8, 9 of the opposite groove 15 have a predetermined distance from one another.

[0023] The chuck, fitted to the fixture 1 , fixed to the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clamping force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com