Internal compensation method of A.C motor and its winding connection method

An AC motor and compensation winding technology, applied in the field of internal compensation windings, can solve the problems of low reliability, large starting current, and the effect of capacitance compensation cannot be extended to the inside of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

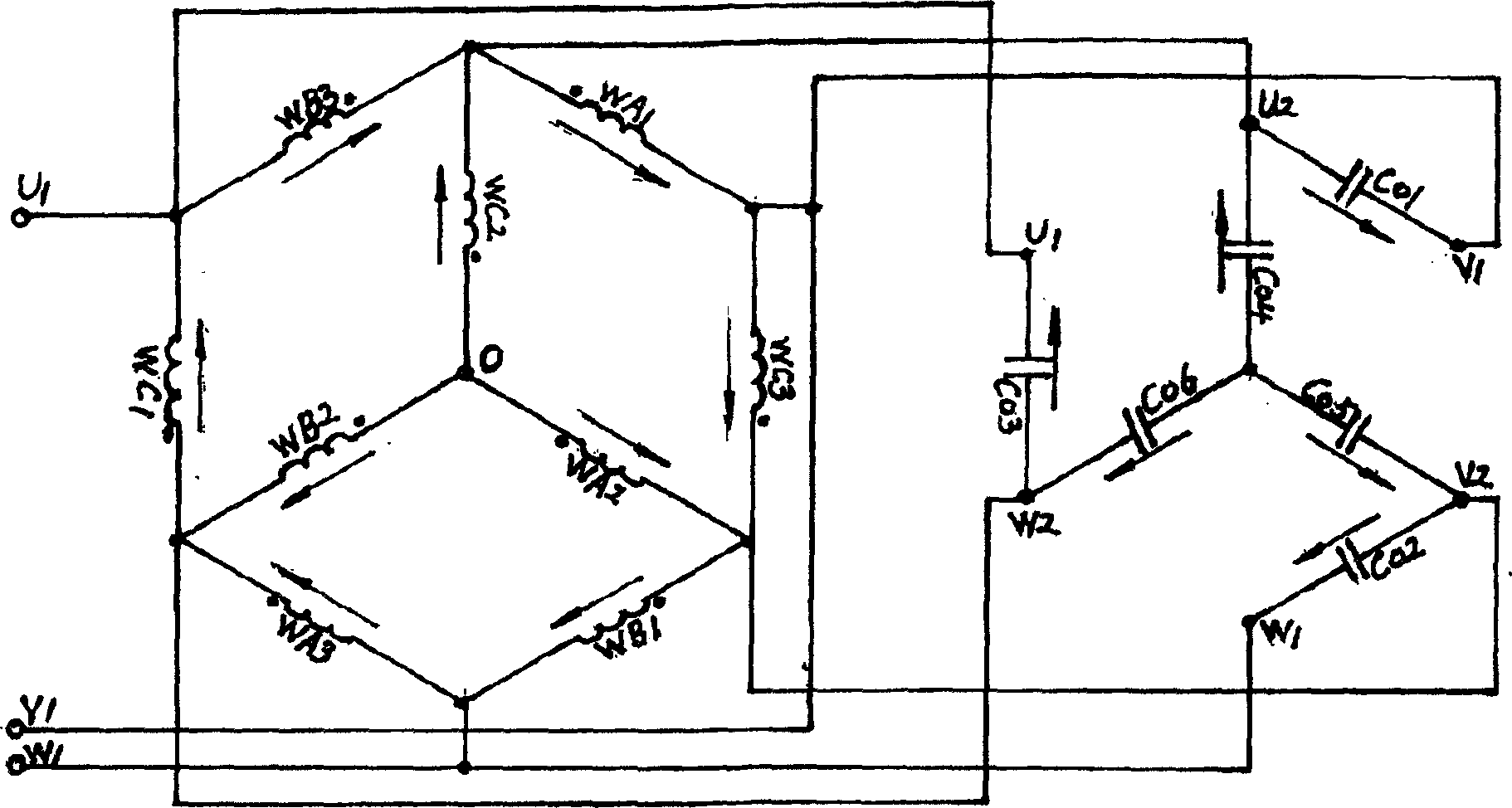

Embodiment 1

[0016] The stator core, squirrel-cage rotor, shell, accessories, AC contactor, single-phase 250V power capacitor and 400V power capacitor bank of an ordinary three-phase asynchronous motor are used together. The stator core is 72 slots, the number of poles is 6 poles, three power terminals and three compensation terminals are set in the junction box, and the conventional double-stacked winding process is used. A slot number corresponds to a coil, and the phase table of the slot number on the upper side of the coil is used to indicate the arrangement and wiring of the stator coil. The connection direction from which the first end enters the coil and exits from the end is called positive connection, and vice versa, it is reverse connection. Correspondingly, a negative sign is added before the slot number representing the reverse connection. The arrow marked next to each winding segment in the wiring diagram is both the positive direction of the voltage and the positive direction of ...

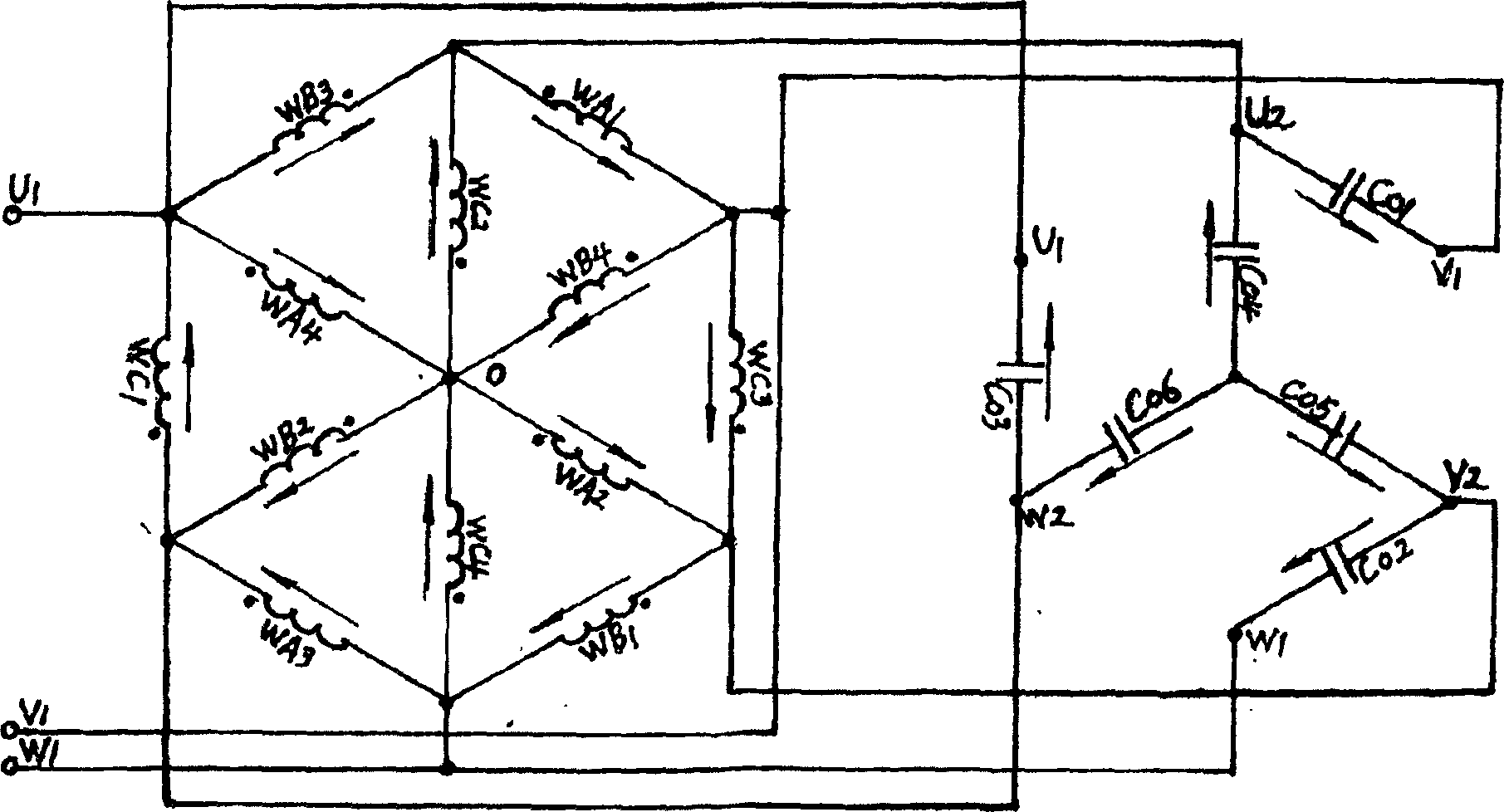

Embodiment 2

[0020] The number of stator slots is 72 slots, the number of poles is 4 poles, each winding adopts the same number of turns, and the winding pitch y=1-17. Still using the slot number phase table method described in Example 1 to show that each phase stator winding is divided into four winding segments, the coil arrangement of a total of twelve winding segments is shown in Table 2:

[0021] Phase A

[0022] in figure 2 U 1 , V 1 , W 1 Use an AC contactor at the three ends to connect to the positive phase sequence three-phase AC power source in turn. 2 With V 1 , V 2 With W 1 , W 2 With U 1 Connect both ends to C 01 , C 02 , C 03 Three single-phase capacitors, and the U 2 , V 2 , W 2 Three-terminal connection C 04 , C 05 , C 06 Three-phase capacitor bank. When the method in this example is used for a load with a small moment of inertia, all of its capacitors can be fixedly connected to the compensation terminal and the power terminal through the current detection device. T...

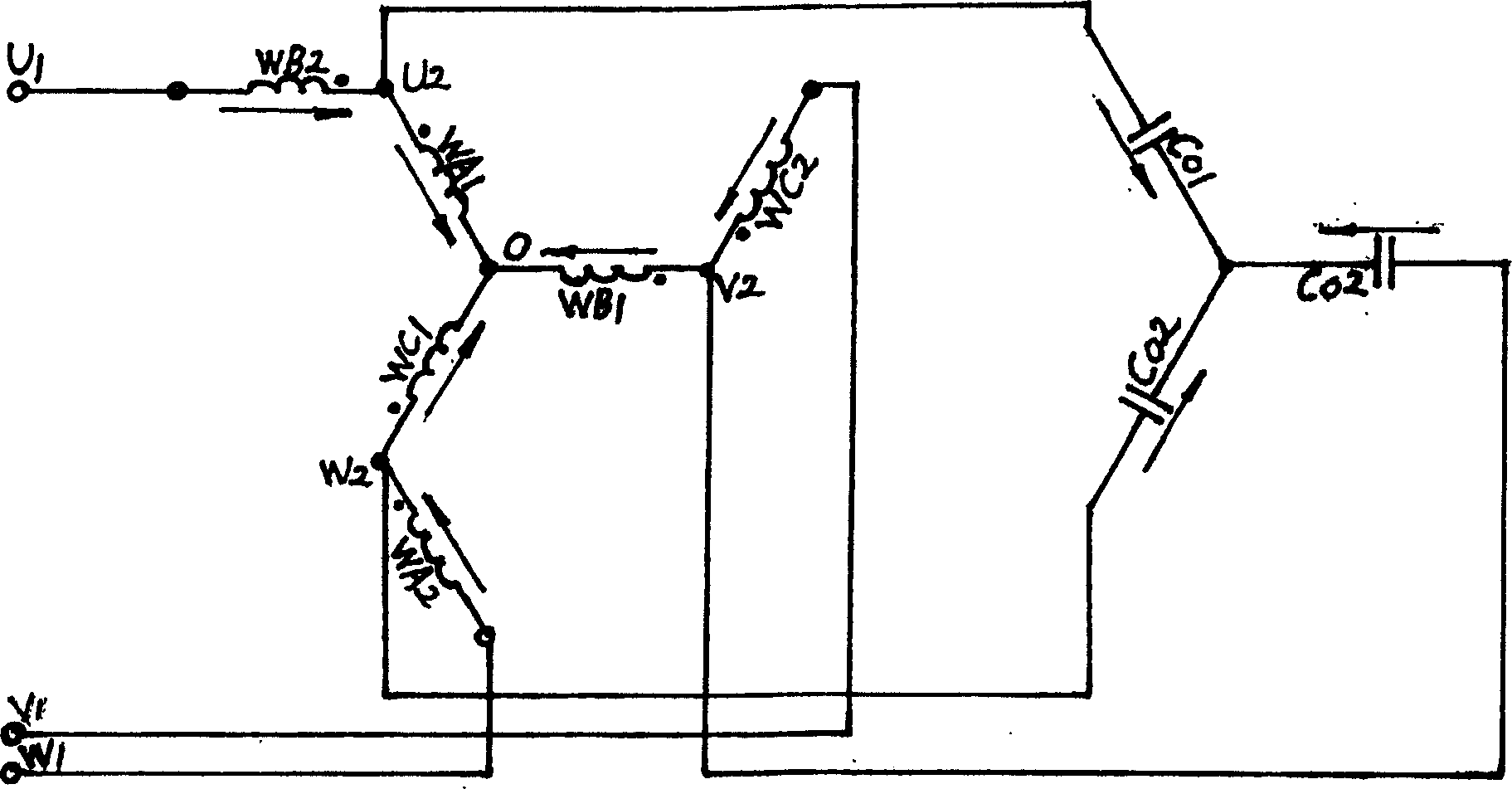

Embodiment 3

[0024] In this example, the number of stator slots is 60, the number of poles is 4, and the winding uses equal turns and the pitch Y=1-14. The connection method of each phase winding is divided into two winding segments, see image 3 , The coil arrangement of each winding segment is shown in Table 3:

[0025] Table 3 Slot number table of 60-slot 4-pole 6-segment winding arrangement:

[0026] Phase A

Phase B

Phase C

WA 1

1 2 3 4 5

31 32 33 34 35

WB 1

11 12 13 14 15

41 42 43 44 45

WC 1

21 22 23 24 25

51 52 53 54 55

WA 2

-16 -17 -18 -19 -20

-46 -47 -48 -49 -50

WB 2

-26 -27 -28 -29 -30

-56 -57 -58 -59 -60

WC 2

-36 -37 -38 -39 -40

-6 -7 -8 -9 -10

[0027] When the three zigzag series winding sections of this example are connected to form a three-phase zigzag star connection, the U 2 , V 2 , W 2 Three compensation terminals connected to C 01 , C 02 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com