Device and method for coating powder

A technology of powder coating and powder coating, which is applied to the device, spray device, electrostatic spray device and other directions for coating liquid on the surface, which can solve the problems of cumbersomeness and hindering the efficiency of coating operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

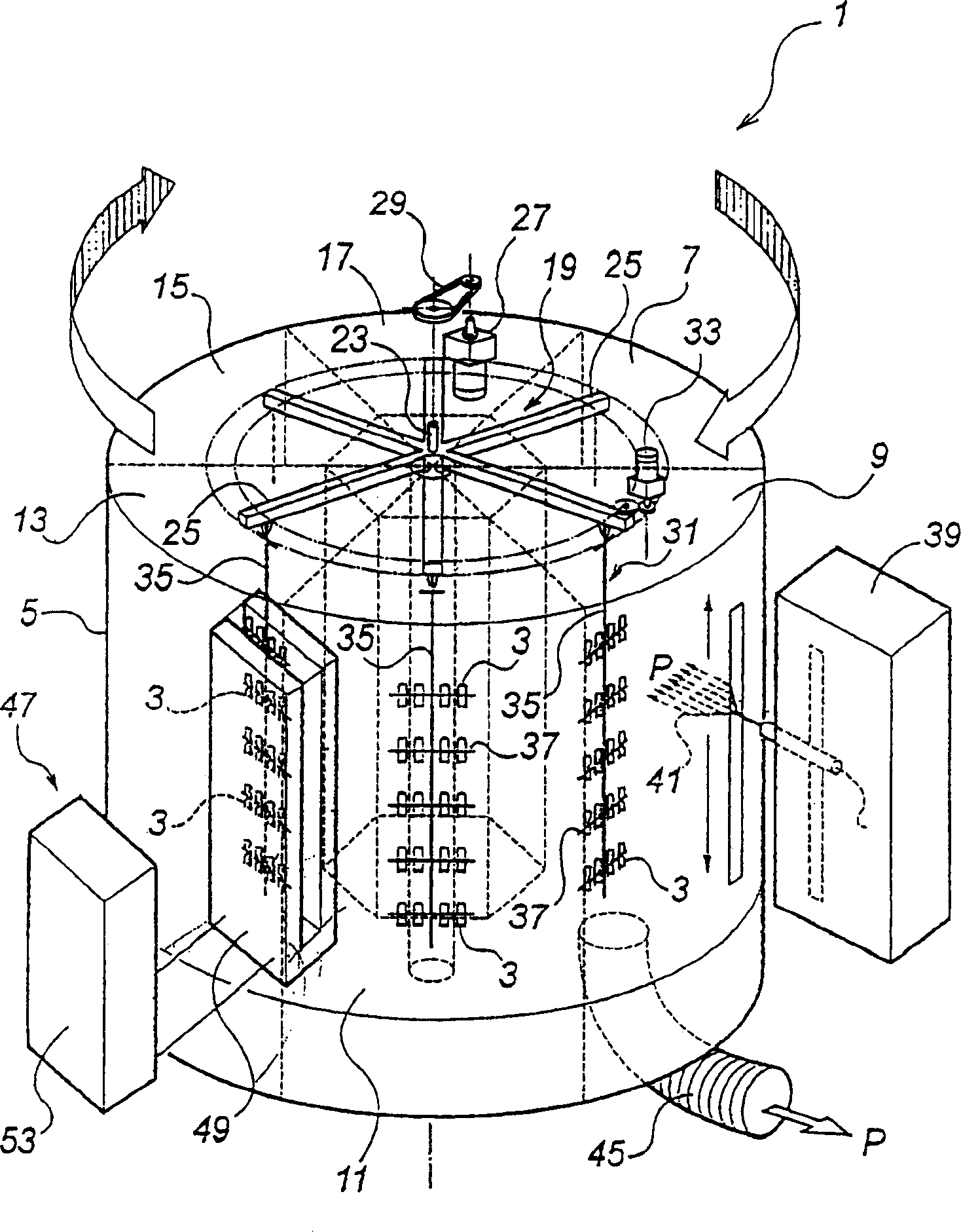

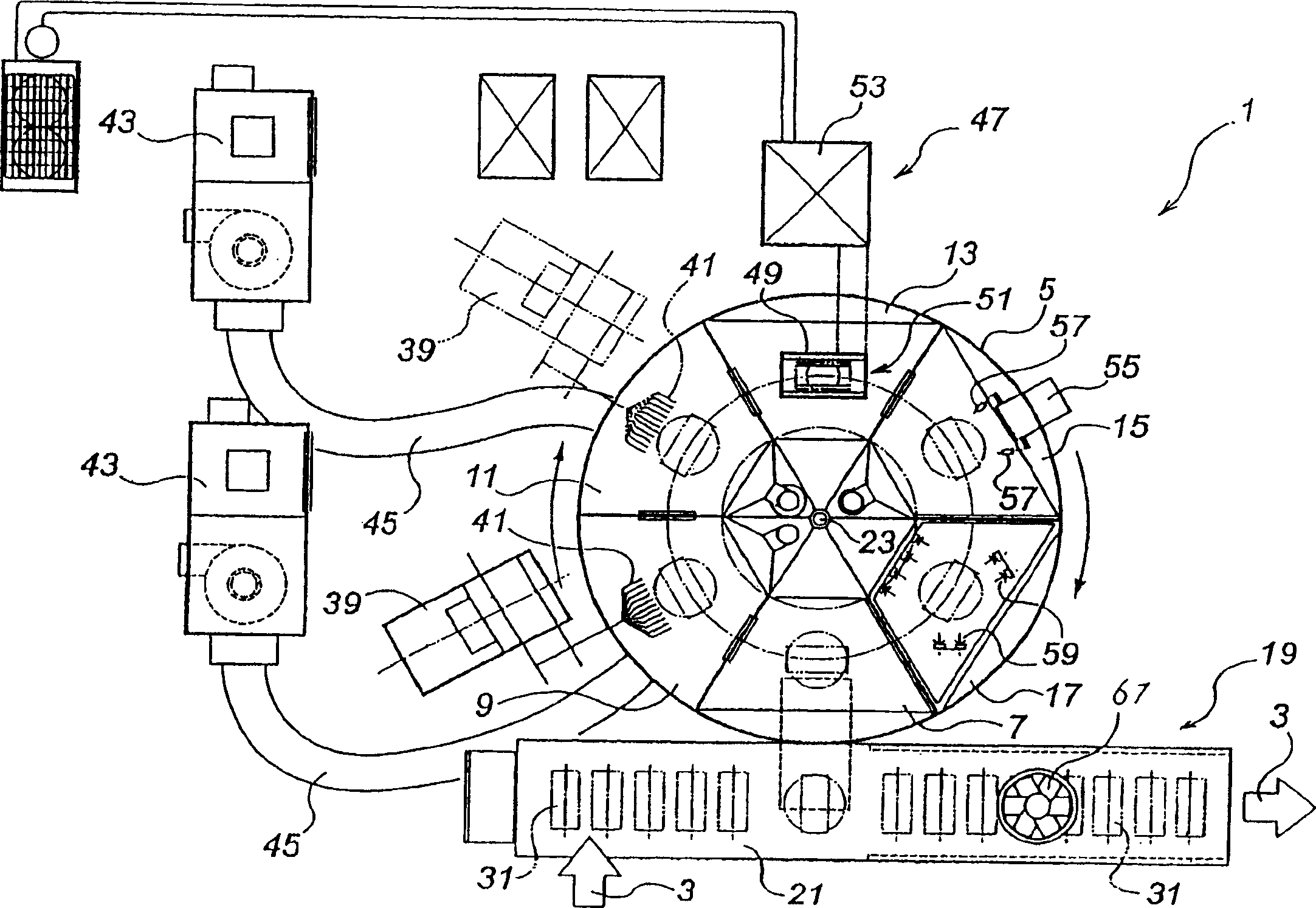

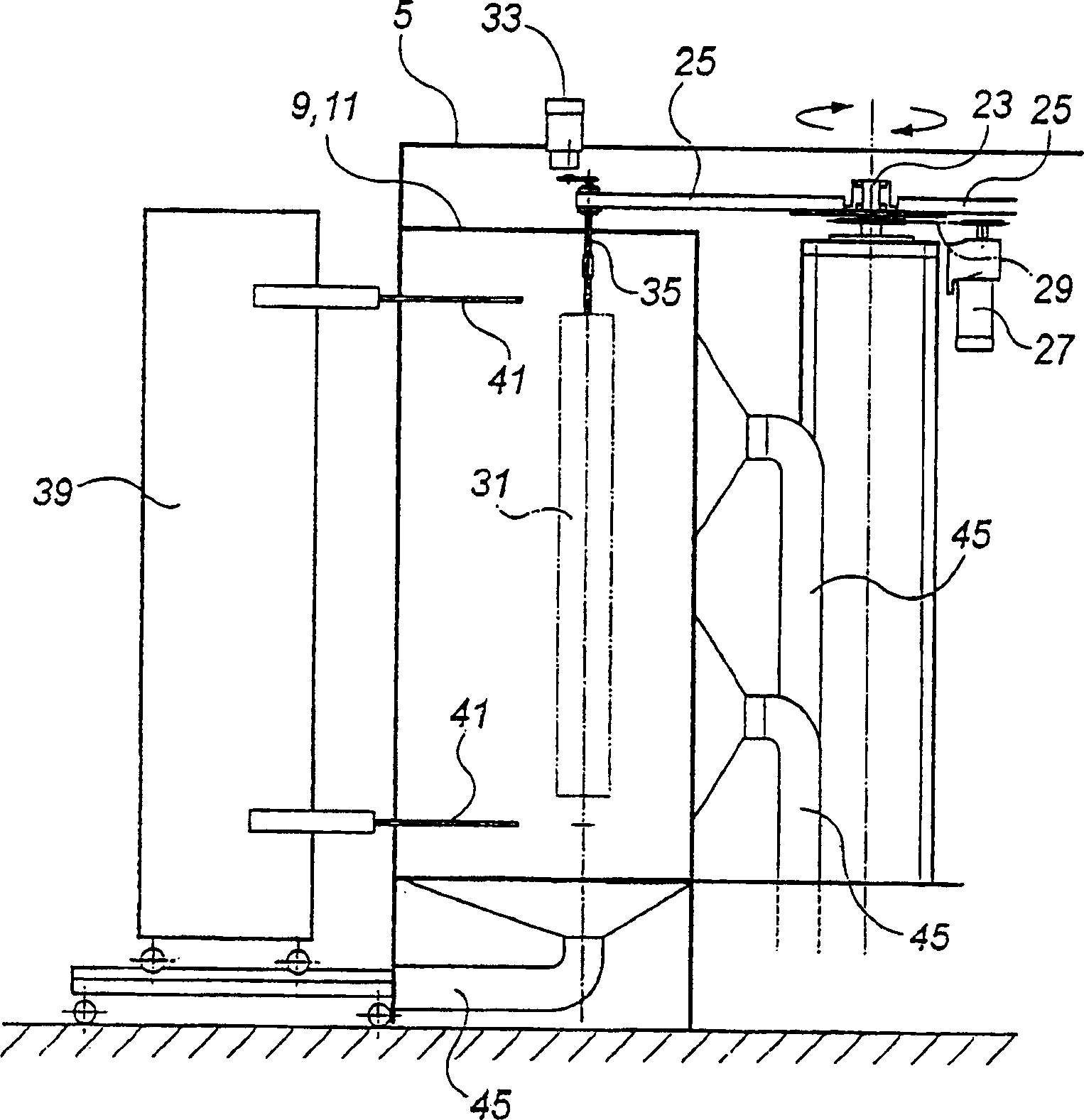

[0063] Below, according to Figure 1~4 The powder coating apparatus 1 of the first embodiment will be described.

[0064] The powder coating apparatus 1 of the present invention is used when coating a steel object to be coated 3 having a complex shape such as an iron pipe joint, for example.

[0065] Specific as figure 1 , 2 Shown, taking the inside of the operation part 5 of cylindrical container shape as an example, it is divided into six processing parts 7, 9, 11, 13, 15, 17, and each processing part 7, 9, 11, 13, 15, In 17, there is an accessory device for individual processing and a conveying device 19 for holding and conveying the object 3 to be coated.

[0066] Among them, the communication processing part 7 receives the object to be coated 3 transported from the outside by the conveyor 21 into the operation part, and after a series of painting operations is completed, it again acts as an external communication part for delivery to the external conveyor 21 . A rotar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap