Method for manufacturing micro electromechanical Fabry-perot device

A manufacturing method, micro-electromechanical technology, applied in light guides, optics, instruments, etc., can solve problems such as difficulty in meeting the precision requirements of process parameters, inability to manufacture micro-electromechanical Fabry-Perot devices, and lack of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention will be described below with reference to related drawings.

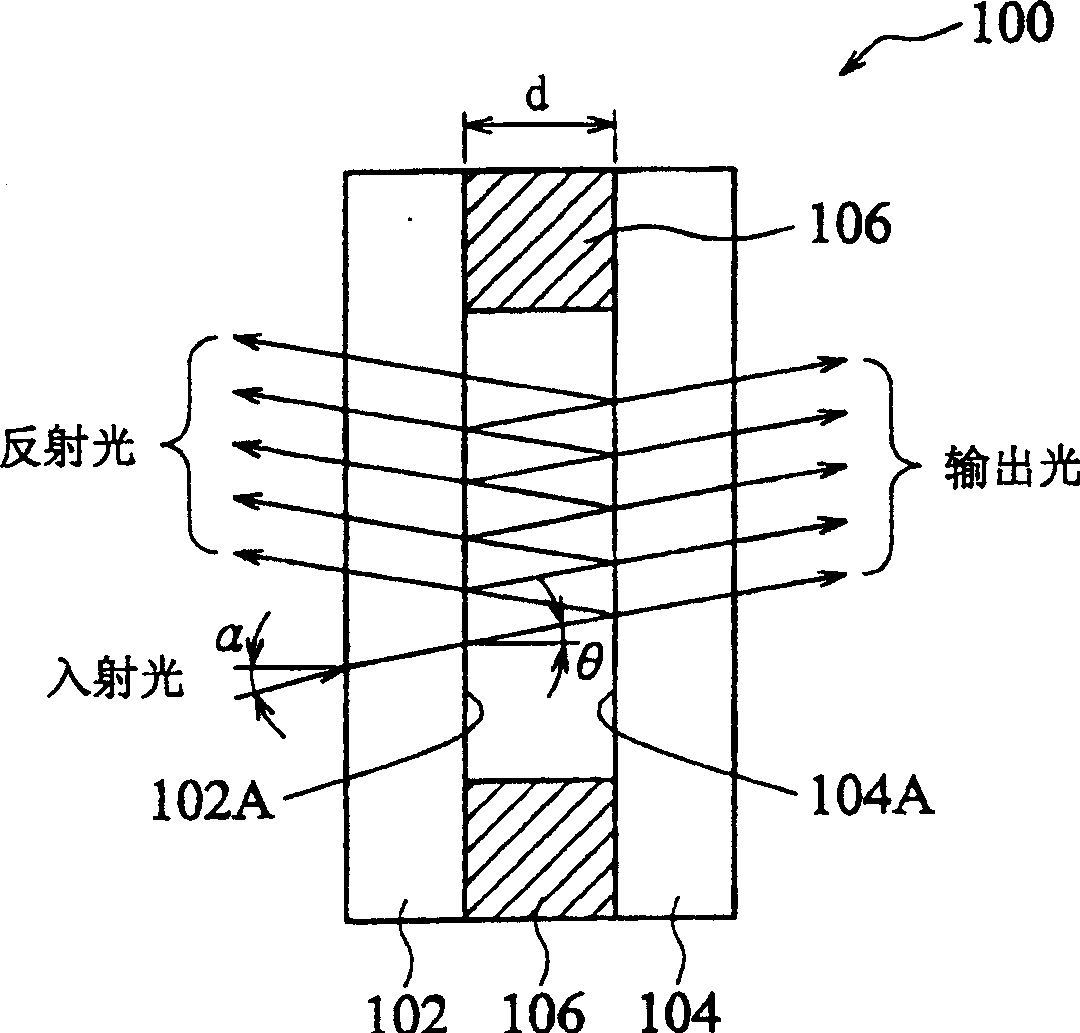

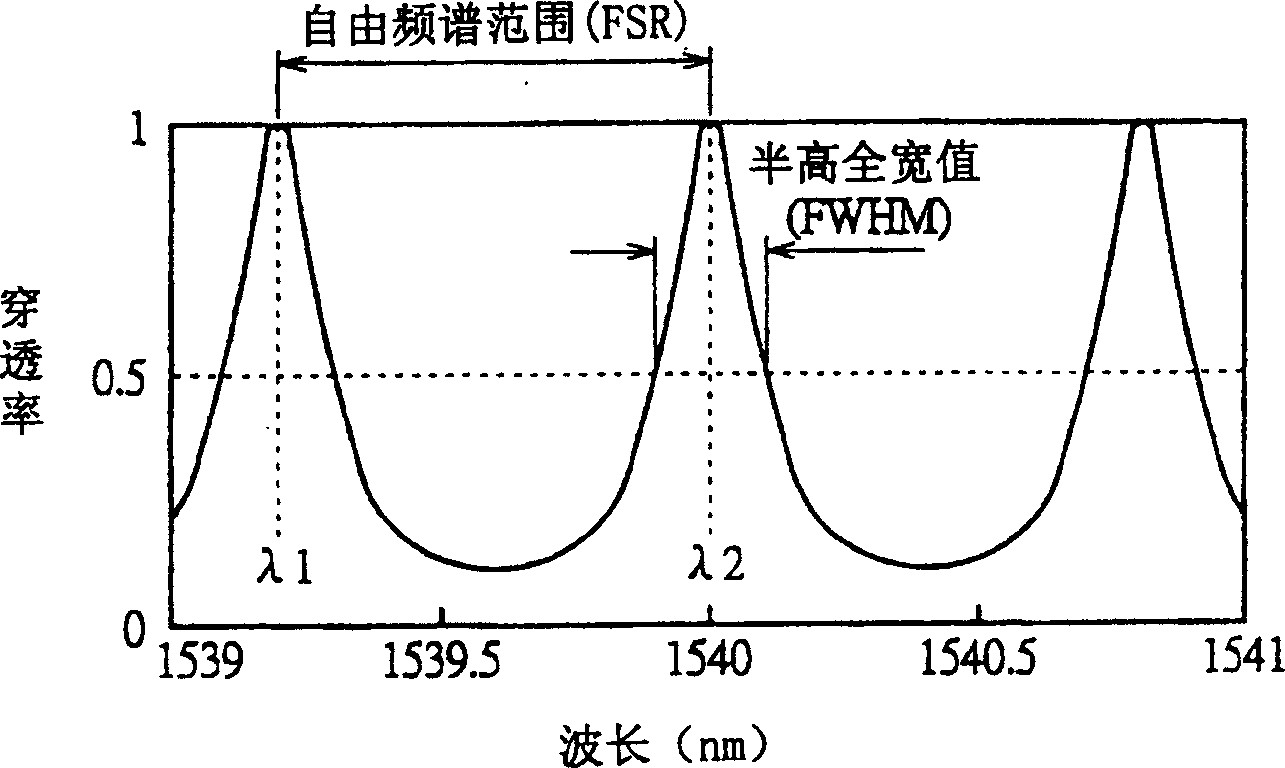

[0045] Figure 5A to Figure 5C It is a preferred embodiment of the manufacturing method of the MEMS Fabry-Perot device according to the present invention, showing a schematic cross-sectional view of its manufacturing procedure.

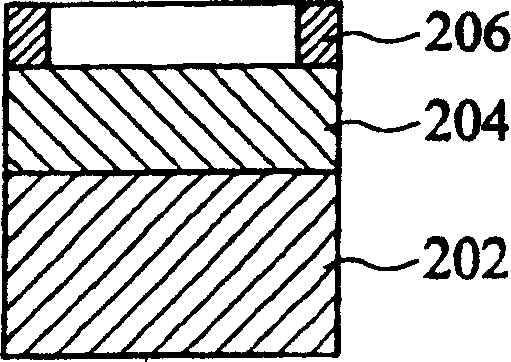

[0046] Such as Figure 5A As shown, firstly, a substrate 12 is provided, and the substrate 12 is composed of a silicon wafer or a glass substrate coated with a reflective film 12A. Next, a photomask 14 is covered on the base material 12, and the photomask 14 is used to define the coating area required for the subsequent procedure.

[0047] Then as Figure 5B As shown, using a film deposition method such as Physical Vapor Deposition (Physical Vapor Deposition; PVD) or Chemical Vapor Deposition (Chemical Vapor Deposition; CVD), deposition materials such as dielectric materials or metal materials (such as silver or aluminum) 18 is depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com