Method of preventing local wear and erosion of impeller machine

A technology of partial wear and impeller machinery, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., and can solve problems such as cavitation and surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] This method is described in conjunction with accompanying drawing: method comprises the following steps:

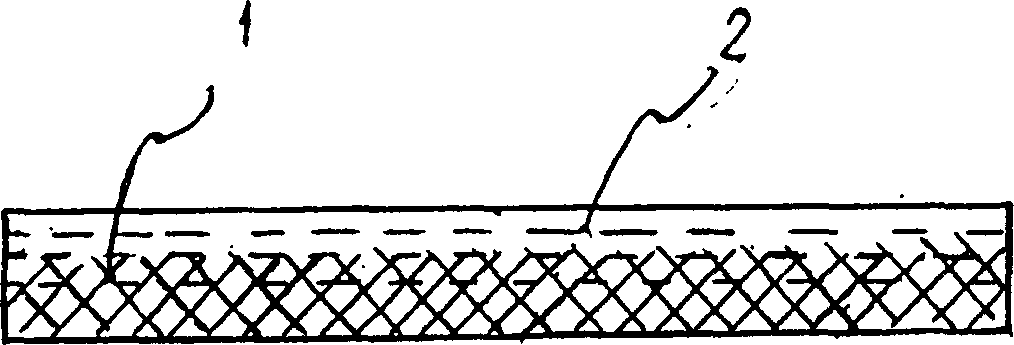

[0012] 1) by figure 1 As shown, clean the metal mesh 1 with a thickness of 0.1-0.8mm, press it into the polymer material 2 by hot pressing, and bond it with the polymer material. The polymer material layer 1 reinforced by the metal mesh A thin layer of wear-resistant and cavitation-resistant reinforced polymer material is formed on one side, and a metal mesh with a thickness of 0.1-0.8mm is exposed on the other side. The polymer material can be ultra-high molecular weight polyethylene, high-density polyethylene, etc., and the metal mesh is steel wire. Mesh, copper wire mesh or aluminum wire mesh, etc., it is better to use steel wire mesh;

[0013] 2) Brush the metal surface to be anti-corrosion and clean it with acetone;

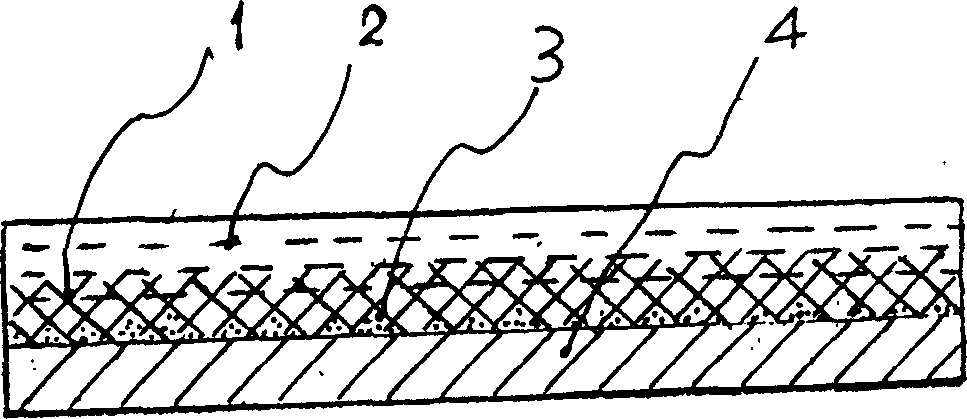

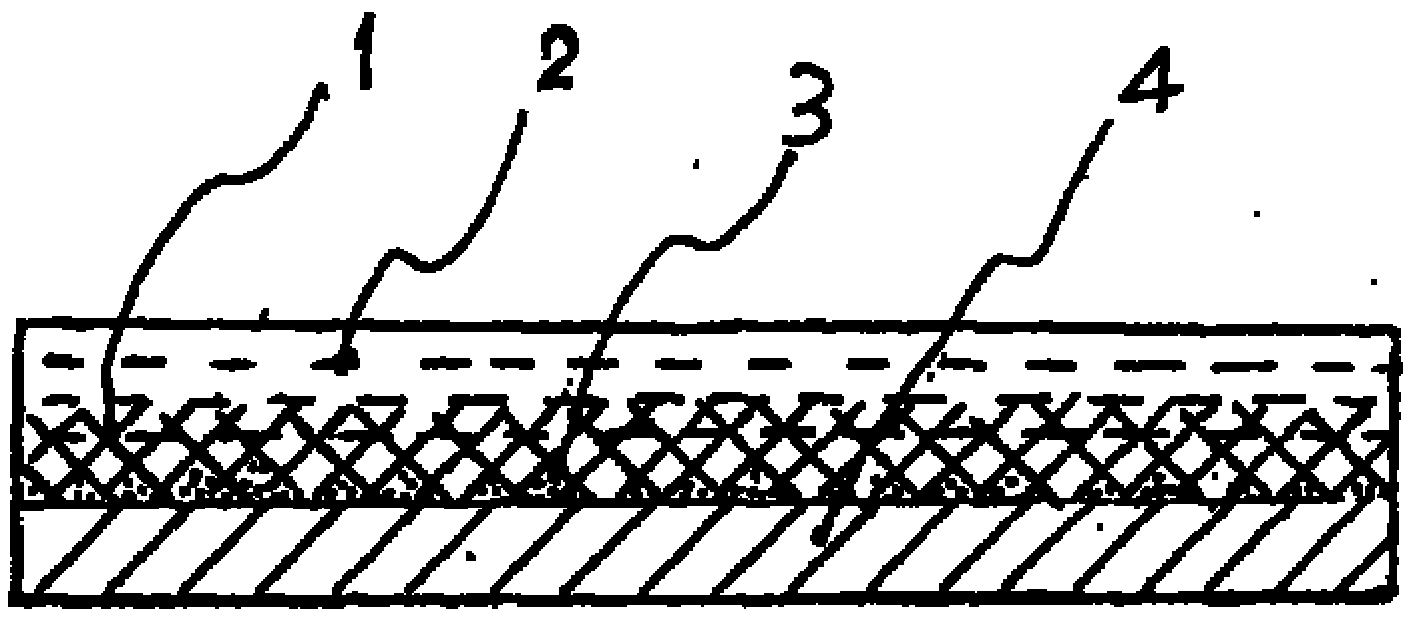

[0014] 3) by figure 2 As shown, the metal mesh 1 exposed on the side of the polymer material is pasted on the metal surface 4 to be protecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com