Automobile engine cooling liquid and its preparing process

A technology for automobile engine and coolant, applied in the field of coolant, can solve the problems of poor coolant stability, unstable coolant, low solubility, etc., and achieve good corrosion inhibition effect, stable and reliable quality, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1. Add 20kg of deionized water to a reactor with a stirrer, then add 30kg of ethylene glycol, 0.1kg of phosphoric acid and 1kg of borax, and stir until they are completely dissolved.

[0033] Step 2, add 50kg of deionized water to another reactor with agitator, then add 1kg of triethanolamine, 0.1kg of sodium hydroxide, 0.1kg of 2-amylaminebenzimidazole (PAB), 0.2kg of mercaptobenzothiazole Sodium (NACAP), 0.1kg of 3-(trihydroxymethylsiloxane)-propanyl-monophosphate phosphate and 0.1kg of sodium silicate, fully stirred until completely dissolved.

[0034] Mix and stir the materials in step 1 and step 2 evenly, and add an appropriate amount of simethicone emulsion and direct sunfast blue to prepare the cooling liquid 1 of the present invention.

Embodiment 2

[0036] Step 1. Add 30kg of deionized water into the reaction kettle with agitator, then add 40kg of ethylene glycol, 0.05kg of phosphoric acid and 0.51kg of borax, and stir until they are completely dissolved.

[0037] Step 2, add 30kg of deionized water to another reactor with agitator, then add 0.5kg of triethanolamine, 0.05kg of sodium hydroxide, 0.05kg of 2-amylamine benzimidazole (PAB), 0.15kg of mercaptothiazole di Sodium (NATD), 0.05kg of 3-(trihydroxymethylsiloxane)-propanyl-monophosphate phosphate and 0.05kg of sodium silicate, fully stirred until completely dissolved.

[0038] Mix and stir the materials in step 1 and step 2 evenly, and add an appropriate amount of simethicone emulsion and direct sunfast blue to prepare the cooling solution 2 of the present invention.

Embodiment 3

[0040] Step 1. Add 25kg of deionized water into the reaction kettle with agitator, then add 50kg of ethylene glycol, 0.15kg of phosphoric acid and 1.5kg of borax, and stir until all of them are dissolved.

[0041] Step 2, add 25kg deionized water in another reactor with agitator, then add 1.5kg triethanolamine, 0.15kg sodium hydroxide, 0.15kg2-pentylamine benzimidazole (PAB), 0.15kg mercaptothiazole di Sodium (NATD), 0.1kg sodium mercaptobenzothiazole (NACAP), 0.15kg 3-(trihydroxymethylsiloxane)-propanyl-monophosphate phosphate and 0.15kg sodium silicate, fully stirred until completely dissolved .

[0042] Mix and stir the materials in step 1 and step 2 evenly, and add an appropriate amount of simethicone emulsion and direct sunfast blue to prepare the cooling liquid 3 of the present invention.

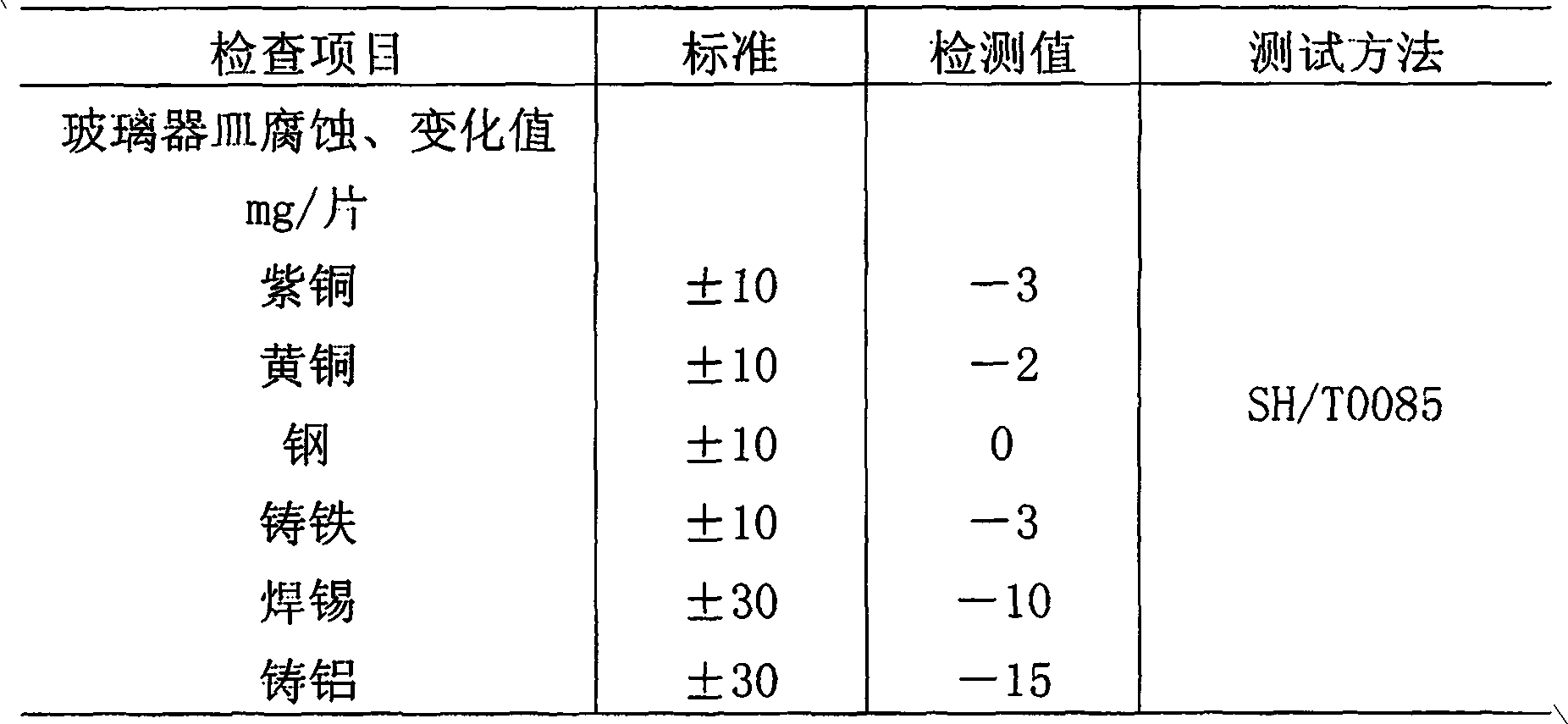

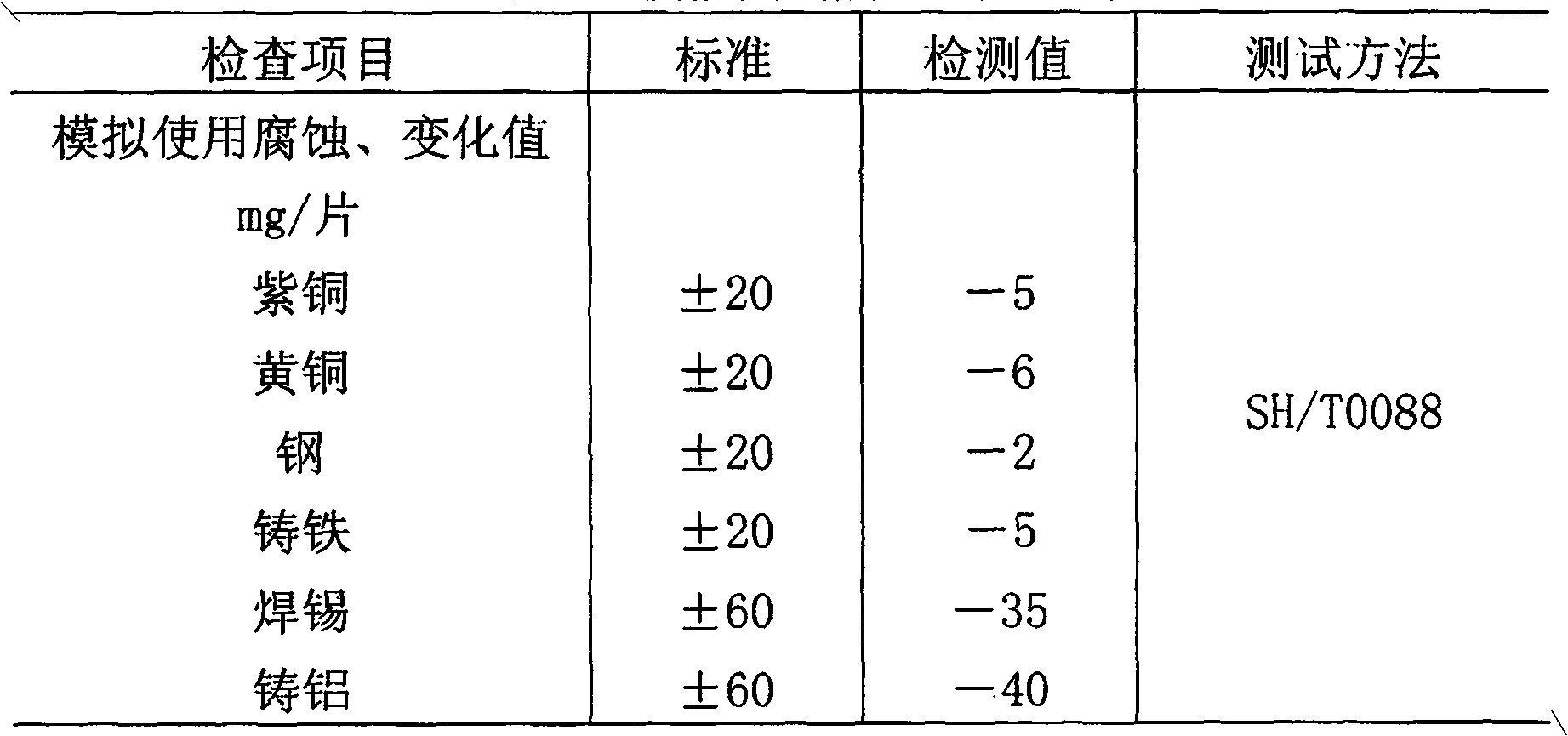

[0043] The cooling liquid 1 of the present invention is subjected to a glassware corrosion test, the cooling liquid 2 of the present invention is subjected to a simulated practical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com